Episode 26: Achim Fischereder, Hexcel

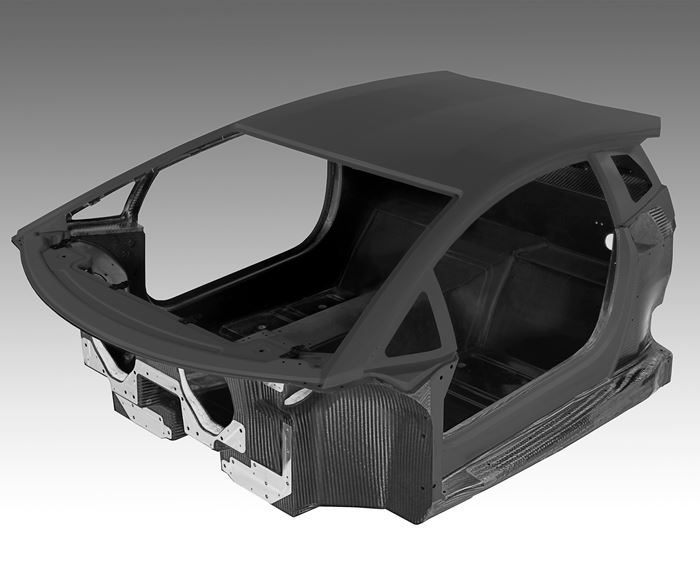

Achim Fischereder, director of sales and marketing for the automotive business segment at Hexcel, discusses the state of composites in cars and trucks today and the outlook for the future.

Hexcel's Achim Fischereder on composite use in cars and trucks today and the future of composites in automotive.

In this episode of CWTalks, CW editor-in-chief Jeff Sloan interviews Achim Fischereder, director of sales and marketing for the automotive business segment at Hexcel (Stamford, Conn., U.S.).

Fischereder has been at Hexcel for almost eight years, working almost exclusively on the automotive side of the business. In this podcast he discusses composite use in cars and trucks today, the future of composites in automotive, and what the composite industry needs to keep in mind as it considers car consumers.

You can listen to the full CW Talks interview above or visit:

Related Content

-

Plant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

-

Revisiting the OceanGate Titan disaster

A year has passed since the tragic loss of the Titan submersible that claimed the lives of five people. What lessons have been learned from the disaster?

-

Plant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.