Machina Labs awarded contract for robotic composites manufacturing

The initiative, enabled by the U.S. Air Force, is designed to advance metal tooling for high-rate production of composites.

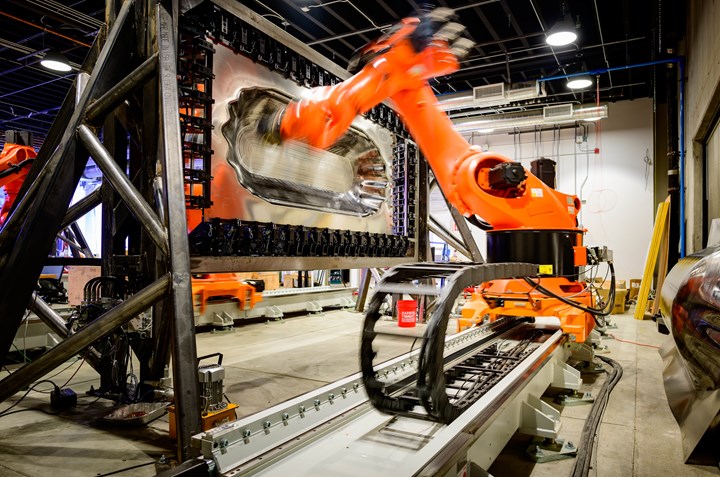

Advanced manufacturing company Machina Labs (Los Angeles, Calif., U.S.) has been awarded $1.6 million by the U.S. Air Force (USAF, Washington, D.C., U.S.) to advance and accelerate the development of its robotic technology for manufacturing of metal tooling for high-rate production of composites.

Higher vehicle production rates in comparison to current rates is anticipated as experts project that the airline industry will need to triple its fleet to about 60,000 airplanes over the next 20 years. With respect to military applications, there is a similar drive towards balancing mission agility, sustainment and vehicle cost — this has been giving rise to emerging air vehicle concepts like the low-cost autonomous collaborative platforms (ACP) program where there is a higher tolerance over limited life and loss of vehicles during operations.

In addition, advanced/urban air mobility (AAM/UAM) vehicles have received considerable commercial traction in recent years. These highly automated, on-demand passenger and air cargo vehicles are anticipated to have production rates in the tens to hundreds of thousands per year. Lightweight, high-strength composite structures are a key enabler for achieving these goals. As such, the factory throughputs of advanced composite structures have to be increased and their production cost lowered.

Machina Labs’ AFWERX Tactical Funding Increase (TACFI) contract will be focused on metal tooling for a fast-cure, out-of-autoclave (OOA) composite processing route. Through its previous contract with the Air Force Research Laboratory (AFRL, Wright-Patterson Air Force Base, Ohio, U.S.), Machina Labs has validated that its tools have vacuum integrity, are dimensionally stable once thermally stabilized and are thermally more responsive than conventional metal tools.

“Machina Labs has demonstrated that its large-envelope, two-robot, incremental sheet metal forming technology can be used for manufacturing of metal tooling for composites, resulting in dramatically reduced tool costs and time-to-market of composite parts,” according to Craig Neslen, manufacturing lead for the ACP Program at AFRL. “At the same time, given that no part-specific hardware is necessary for manufacturing of the sheet metal tools, it is possible to not only fabricate the tools expeditiously, but to quickly accommodate design changes when necessary.”

Machina Labs combines the latest advances in AI and robotics to deliver finished metal products in days — rather not months or years. Robotic sheet forming is the first process enabled by Machina’s patented manufacturing platform. Using material- and geometry-agnostic technology, the platform reportedly outperforms traditional sheet forming methods that rely on custom molds or dies. The technology enables the company to creatively manufacture different designs and material, introducing reportedly unseen flexibility and agility to the manufacturing industry. (Learn more about Machina Labs’ technology in this article’s sidebar)

“We are pleased to advance our work with USAF in order to advance composite tooling for a wide variety of applications,” Babak Raeisinia, co-founder and head of applications and partnerships at Machina Labs, says. “Keeping inventory of tooling is expensive. I believe technology will free up capital and allow organizations such as USAF to transition to an on-demand tooling model.”

Visit sister publication, Additive Manufacturing Media, for more information regarding metal additive manufacturing.

Related Content

Carbon fiber composite pallet revolutionizes freight industry

LOG Point Pallet fuses advanced materials with innovative design and manufacturing to improve supply chains worldwide.

Read MorePlant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read MoreCarbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreRead Next

Vestas implements composites 3D printing to increase efficiency for blade alignment tools

A Markforged digital repository and multi-material 3D printers enable faster, more accurate and less costly manufacture of a variety of tools and blade components across Vestas sites.

Read MoreLighter, stronger, faster bionic hand aided by composites design

Psyonic’s touch-sensing prosthetic hand leverages bionic technology, 3D printing and a carbon fiber composite exterior for light weight, high strength and high-tech functionality.

Read MoreRobotic computed laminography brings X-ray CT resolution to large composite structures

Omni NDE collaborative robots, X-ray end effectors and Voxray’s reconstruction approach enables 5-micron inspection of aerospace parts without size constraints.

Read More