Wind turbines are massive and expensive machines that must function reliably with minimal downtime in order to be as effective as possible. That means there’s no room for error when it comes to manufacturing and installation. As a result, wind turbine manufacturer Vestas (Aarhus, Denmark) has depended on specialized inspection gauges at its manufacturing facilities and inspection sites, often requiring parts to be sent between various facilities. However, this process can be time consuming, and adds onto the time and production costs needed to produce specialized wind blade components.

To eliminate these bottlenecks, in 2021 Vestas launched a program at its blade production facilities to produce many of these components in a more streamlined, digitized way via additive manufacturing (AM). Vestas’ direct digital manufacturing (DDM) program uses Markforged’s (Cambridge, Mass., U.S.) cloud-based, AI-powered Digital Forge AM platform, 3D printers and materials to produce thousands of specialized parts quickly and on the site where they are needed.

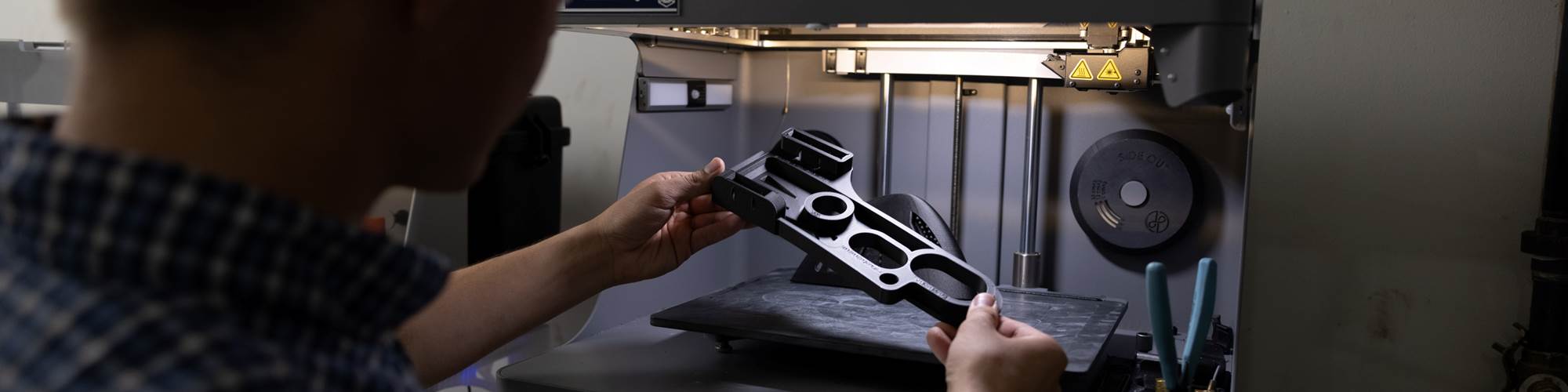

One of these parts is a carbon fiber-filled composite top center (TC) marking tool (shown in images and in video below) that is used by the wind blade assembly team in the field. Using the tool as a measurement, an indicator mark is placed on the root of the blade to ensure the blade is aligned at the correct pitch during installation. This tool, which originally took weeks to manufacture, ship and then validate for use, is now being made in only a few days.

Previously, Vestas machined these tools from metal, and validation involved shipment of the tools to a facility to check alignment against the blades themselves — this process could take about three weeks including manufacture and validation.

Now, with the DDM system in place, the tools can be designed anywhere and then printed directly at the blade facility using Markforged’s X7 fused deposition modeling (FDM) printer and Onyx carbon fiber-filled nylon blend material. The Blacksmith tool within Markforged’s software platform performs digital inspection and calibration of the tool and generates a calibration report, eliminating the need for a physical inspection and calibration step. The switch to composites also results in 85% total weight savings for the part.

Today, the DDM program is said to include more than 2,000 total Vestas parts, including composite parts like the TC marking tool. The design files for all of these parts are stored in a Markforged Eiger cloud-based digital repository. This enables employees at any Vestas location — even those with little or no AM expertise — to quickly search for and print fiber-reinforced composite parts on their local X7 printers.

According to Jeremy Haight, principal engineer – additive manufacturing and advanced concepts at Vestas, “Our approach is end to end. We provide the physical article in near real time to a variety of places. It’s the closest thing to teleportation I think you can get.”

Thanks to the repository, the Vestas team can manufacture consistent, up-to-spec parts at a moment’s notice, anywhere in the world without the need for specialists at global facilities. This is said to have dramatically reduced shipping and freight costs, as well as manufacturing lead times. Most importantly, the Vestas team no longer has to worry about parts failing compliance tests because they are printed on-demand and in-house using exact digital specifications. Also, tool accuracy is verified using Markforged Blacksmith for in-process inspection, analysis and reporting.

In 2022, Vestas says it will begin rolling out DDM for inspection gauge tooling beyond its blades to facilitate on-demand gauge production at all 23 of its manufacturing locations. Vestas has also partnered with fastener and assembly materials supplier Wurth (Künzelsau, Germany) to build an additive ecosystem and manage an inventory of spare parts made with Markforged’s Digital Forge platform to support maintenance, repair and overhaul (MRO) for local field support and other suppliers.

Once the initial rollout is complete, Vestas will turn its attention to implementing a more in-depth, end-to-end process at its sites. For example, the company is making it easier for individuals at any Vestas site with the right permissions to scan a part code or search for a part in its enterprise asset management (EAM) and enterprise resource planning (ERP) systems, and have it automatically sent to the right local 3D printer. This centralized control of users, printers and parts inspection, using Blacksmith and Eiger Fleet, will ensure high-quality, high-performing tools and end-use parts that do the jobs they’re designed to do.

Related Content

JEC World 2022, Part 1: Highlights in sustainable, digital, industrialized composites

JEC World 2022 offered numerous new developments in composites materials, processes and applications, according to CW senior editor, Ginger Gardiner, most targeting improved sustainability for wider applications.

Read MoreMaterials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

Read MoreForvia brand Faurecia exhibits XL CGH2 tank, cryogenic LH2 storage solution for heavy-duty trucks

Part of its full hydrogen solutions portfolio at IAA Transportation 2022, Faurecia also highlighted sustainable thermoplastic tanks and smart tanks for better safety via structural integrity monitoring.

Read MoreMaterials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

Read MoreRead Next

CW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)