Joby delivers eVTOL aircraft to Edwards Air Force Base ahead of schedule

Composites-intensive air taxi is delivered six months ahead of schedule for use in logistic mission demonstrations by the U.S. Air Force and AAM-focused research by NASA.

Joby Aviation Inc. (Santa Cruz, Calif., U.S.) has announced the delivery of its first electric vertical takeoff and landing (eVTOL) aircraft to Edwards Air Force Base (Edwards AFB, Calif., U.S.) approximately six months ahead of the expected 2024 delivery date. On-base operations with Joby aircraft will be used to demonstrate a range of logistics missions, including cargo and passenger transportation, and will be operated by Joby and U.S. Air Force personnel. In partnership with the U.S. Air Force, NASA will also use the aircraft for research focused on how these aircraft could fit into the national airspace, benefiting the entire air taxi industry.

Joby’s aircraft, which has already begun flying at Edwards AFB, is believed to be the first electric air taxi to be stationed on a U.S. military base and the first delivery of an electric air taxi in the U.S., as part of Joby’s $131 million AFWERX Agility Prime contract with the U.S. Air Force. The company’s current and previously completed work with the Department of Defense (DOD) represents a total potential contract value of $163 million.

The Agility Prime contract includes the provisioning of up to nine aircraft to the U.S. Air Force and other federal agencies. A second aircraft is planned to be delivered to Edwards in early 2024.

The aircraft, which was the first built on Joby’s pilot production line in Marina, Calif., U.S., will be stationed at Edwards AFB for at least the next year, with charging and ground support equipment provided on-base by Joby in a facility purpose-built by the Air Force for joint flight test operations. The U.S. Air Force and Joby will conduct joint flight testing and operations to demonstrate the aircraft’s capabilities in realistic mission settings. On-base operations will also include the training of Air Force pilots and aircraft maintenance crews, which will provide the DOD with valuable insight into the performance of eVTOL aircraft and will give Joby on-the-ground operational and training experience as the company prepares for the launch of commercial passenger service in 2025.

Read “Joby selects Dayton, Ohio, for first scaled eVTOL manufacturing facility”

“We’re proud to join the ranks of revolutionary aircraft that demonstrated their capabilities at Edwards Air Force Base, including the first American jet fighter, the first supersonic aircraft and many others that have pushed the boundaries of aviation technology,” JoeBen Bevirt, founder and CEO of Joby, says. “The longstanding support of the DOD and NASA has been critical to the rapid development of electric aviation and eVTOL aircraft, and demonstrates how successful public-private partnerships can bring new technology to life at speed.”

Joby’s partnership with the DOD dates back to its 2016 engagement with the Defense Innovation Unit (DIU), which granted the company early funding as well as access to test ranges and expertise that have aided its aircraft development program.

“Agility Prime’s stated objective in 2020 was to work towards an operational capability for transformative vertical lift in the DOD by 2023. The arrival of Joby’s aircraft at Edwards AFB is an important step towards achieving this objective,” says Col Elliott Leigh, AFWERX director and CCO for the Department of the Air Force.

In partnership with the U.S. Air Force’s AFWERX program, NASA will also be supporting this testing at Edwards AFB with NASA’s pilots, researchers and equipment as part of its commitment to advancing the advanced air mobility (AAM) industry as a whole, for the benefit of all. NASA’s Armstrong Flight Research Center is located on Edwards AFB, and has a long history of supporting important technological milestones in aviation and space — supersonic and hypersonic flight, digital fly-by-wire control systems and the space shuttles.

“NASA’s participation in the Joby and AFWERX project will provide our researchers with hands-on experience with a representative eVTOL vehicle, concentrated on how these types of aircraft could fit into the national airspace for everyday use, that will inform NASA’s effort in supporting the entire eVTOL industry,” NASA research pilot Wayne Ringelberg notes. “The research will include a focus on handling qualities evaluation tools, autonomy and airspace integration, which is all needed research to push the industry forward.”

Related Content

Joby plans to double U.S. eVTOL manufacturing capacity

Joby and Toyota are finalizing strategy to ramp up to four aircraft/month in 2027 at California and Ohio facilities.

Read MoreOn the radar: Innovations in composite battery enclosures

A look at recently reported design, material and process innovations for composites-intensive battery enclosures, developed to support the ramp-up of EV and AAM vehicles.

Read MoreWhat you might have missed at Paris Air Show 2025

A surge in defense spending, partnerships in hydrogen propulsion and new combat aircraft agreements, many backed by composites industry leaders, culminated the 55th Paris Air Show.

Read MoreArcher acquires assets from Overair, Mission Critical Composites

Aiming to accelerate its defense aircraft portfolio, acquisitions include a patent portfolio from tiltrotor aircraft specialist Overair, and a composites manufacturing site.

Read MoreRead Next

Lilium commences fuselage assembly for Lilium Jet

First of seven fuselages, to be manufactured and assembled at partner Aciturri’s facility in Spain by the end of 2023, marks a pivotal step in the eVTOL aircraft’s industrialization.

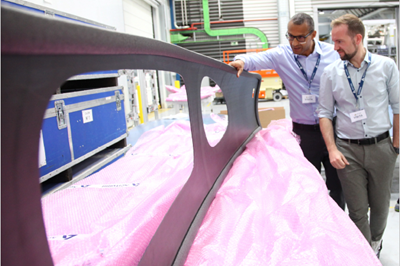

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read More9T Labs selected to supply composite connectors to Dufour eVTOL

Structural thermoplastic composite connectors will further lightweight the Aero2 tilt-wing aircraft.

Read More