Isoco, V Frames, Lehvoss introduce recycled, biopolymer composites to bike frames

Bio-based, performance-optimized composite materials promote more lightweight, stiff and impact resistant E-bike frames and components.

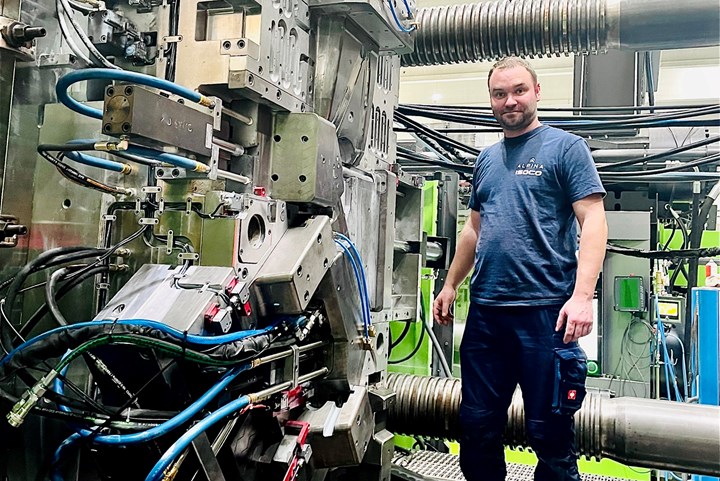

Isoco Bikes (Saalfeld, Germany), an E-bike manufacture producing high-performance injection-molded carbon fiber bike frames, and plastic fabrication company V Frames (Schmiedefeld) have signed an exclusivity agreement with Lehvoss Group (Hamburg) to introduce high-performance fiber-reinforced compounds, including long carbon fiber and biopolymer carbon fiber composite materials, into bike frame and component production.

Per the agreement, V Frames expects to enter mass production of injection-molded carbon fiber composite frames, forks, cockpits and other components for several OEMs by 2027, targeting volumes of 1 million components produced at the Isoco plant in Schmiedefeld, Thuringia. After this, the primary focus is to increase the performance of raw materials to achieve future frames that are more lightweight, impact resistant and feature an increased elastic modulus of up to 50,000 MPa long term (compared to the current 32,000 MPa), further increasing stiffness.

V Frames claims that it already produces some of the most sustainable bike frames on the market, reducing the carbon footprint by 64% compared to traditional aluminum frame production according a life cycle analysis (LCA) performed by the University of Linz, Austria.

V Frames and Lehvoss focus on compounds containing recycled fibers from different industries for new frames, and then recycle its products 100% at the end of their lifetime into new bike component products, providing complete circularity. Production is located in Germany. Isoco’s current production capacility is around three million frames per year.

“Lehvoss is an excellent partner for the development, production and testing of high-performance materials,” Managing Director Michael Müller explains. “With these steps we could push the limits of our technology to new levels. As an example, the Buddy Electric/Isoco X1 frame passed the falling mass test with 23 kilograms at a drop height of 1,120 millimeters, a level far beyond the maximum test requirements of any institute and unreachable by most aluminum and traditional carbon [fiber] frames.”

He says the material used for these high-performance frames is now available for third parties. Additional materials are now being developed and in testing, such as what is contended to be the world’s first bio-based long carbon fiber material for water injection technology [WIT] assisted injection molding.

“Together, we now also push the limits of environmental sustainability with introducing bio-based polyamides reinforced with carbon fibers,” Müller continues. “We are excited to show the results of the new materials in the performance of our frames and components in the next months and years. The approach of V Frames is to provide the perfect material for any frame geometry, any component developed by V Frames, tailor made.”

The new materials introduced in the market under this cooperation consist of:

- Bio-based long carbon fiber materials for WIT injection molding.

- Bio-based polyamides (PA) reinforced with short carbon fibers.

- Economical-, ecological- and performance-optimized materials based on PA, carbon fiber and glass fiber compounds.

All materials developed and tested in the cooperation are available for purchase. For details please contact V Frames and Lehvoss. Material data sheets are available on request.

Related Content

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreAirbus works to improve the life cycle of composites in future aircraft

This companion article to CW's September 2024 Airbus Illescas plant tour discusses recycling, LCA, biocomposites, Fast Track technologies, qualification and more.

Read MoreBladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

Read MoreScaling up thermoplastic composites recycling

Thermoplastic composites are always said to be “recyclable.” Netherlands-based recycler Spiral RTC discusses the process, challenges, applications and opportunities to building a real recycling ecosystem.

Read MoreRead Next

Ultrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read More