Beyond Gravity receives major Amazon contract for scalable CFRP dispenser systems

New Linköping, Sweden, facility to support development work of 3,236 satellites for Project Kuiper.

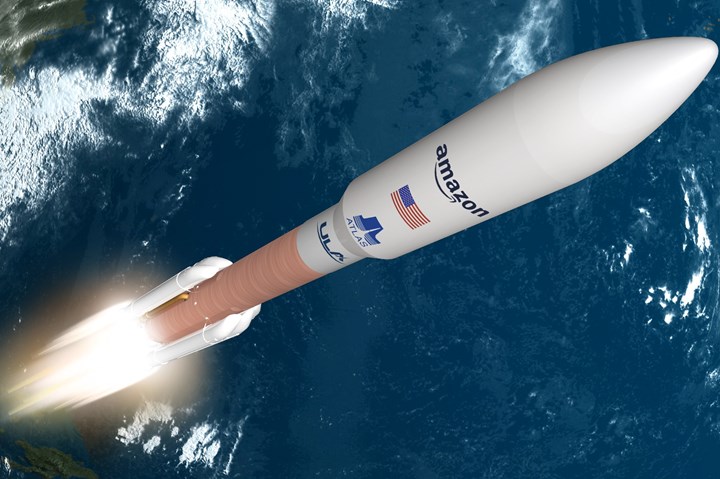

United Launch Alliance’s (ULA) Atlas V launch vehicle for Amazon’s Project Kuiper. Photo Credit: Amazon, Beyond Gravity

Amazon (Seattle, Wash., U.S.) has awarded space technology provider Beyond Gravity (formerly RUAG Space, Zürich, Switzerland) a major contract to design and manufacture the custom, scalable carbon fiber-reinforced polymer (CFRP) dispenser systems for its low-Earth orbit (LEO) satellite network, Project Kuiper. This is reported to be Beyond Gravity’s single largest order in history, which will support dozens of launches and underscore the company’s strong position in the New Space market.

The mission behind the Amazon initiative, Project Kuiper, is to increase global broadband access through a constellation of satellites in LEO. Amazon plans to deploy an initial constellation of 3,236 satellites, all of which will be manufactured by Beyond Gravity at its new facility in Linköping, Sweden, which will double production capacity for the dispensers. which will support the development work, double its production capacity for dispensers and create 60 additional jobs on site. Beyond Gravity’s scalable dispenser systems are able to accommodate multiple medium- and heavy-lift launch vehicles.

“We are honored to be part of such a globally unique project. Together with Amazon, we further contribute to the growth of the European space industry, as we will also source the material and components from a broad European supplier base,” André Wall, CEO of RUAG International, says. For Beyond Gravity, the order is another important step in strengthening the company's position in the fast-growing commercial space markets.

According to Rajeev Badyal, vice president of technology for Project Kuiper at Amazon, “We need a flexible, low-cost dispenser system that works across multiple rockets, and Beyond Gravity has the experience required and the passion to invent alongside our team. We’re proud to be working together and supporting the growth of the European space industry.”

Engineers from Beyond Gravity and Project Kuiper have worked together for nearly two years to develop a flexible, scalable dispenser system suitable for a variety of rockets and payload configurations. The Beyond Gravity dispenser system uses advanced, ultra-lightweight materials to reduce mass, thereby lowering development costs. This supports Amazon's goal of lowering production and deployment costs for its entire satellite system.

In Linköping, Sweden, where the dispenser systems for Project Kuiper are produced, Beyond Gravity broke ground in mid-March on a new dispenser production facility in partnership with the Swedish Space Agency and the city of Linköping. The new facility will be completed by 2023.

Related Content

-

JEC World 2024 highlights: Thermoplastic composites, CMC and novel processes

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.

-

Plant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.