2019 CAMX award, ACE winners illustrate industry trends

Among this year’s award winners are Continental Structural Plastics, the Institut fur Textiltecnik of RWTH Aachen University, LyondellBasell, Fortify, Spirit AeroSystems and more.

Spirit AeroSystems’ ASTRA fuselage panel demonstrator, on display at CAMX 2019. CW photo | Heather Francis

The CAMX 2019 trade show, held Sept. 23-25 in Anaheim, Calif., U.S., showcased the latest processes, materials and solutions in composites manufacturing, and highlighted new and up-and-coming projects and products across a variety of end markets. This year’s CAMX Award and ACMA ACE winners represent some of the best on display at this year’s show and what’s trending in the industry, with innovations ranging from next-generation aerospace parts and high-volume automotive parts, to greener materials and revolutions in composite 3D printing. Here is a rundown of the winners:

The CarbonPro pickup box, winner of the 2019 CAMX Unsurpassed Innovation Award. CW photo | Heather Francis

CAMX Awards: CarbonPro box and laser drilling

CAMX gives two awards each year, one in the Unsurpassed Innovation category and one in the Combined Strength category.

General Motors (Detroit, Mich., U.S.) and Continental Structural Plastics (Auburn Hills, Mich., U.S.) were awarded the CAMX Unsurpassed Innovation award for the CarbonPro chopped carbon fiber/polyamide box for the GMC Sierra Denali pickup truck.

The Institut für Textiltechnik of RWTH Aachen University (Aachen, Germany) took home the CAMX Combined Strength award for its high-accuracy laser drill for cutting holes in carbon fiber preforms for inserts and fasteners.

ACE winners: from SMC to ASTRA

The American Composites Manufacturers Assn. (ACMA; Arlington, Va., U.S.) Awards for Composites Excellence (ACE) are given for exemplary achievement in materials and processes, equipment and tooling, creative design, growth opportunity and sustainability.

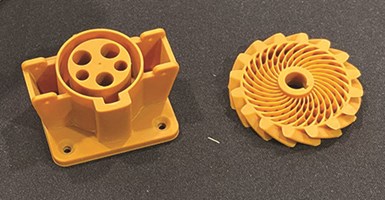

3D-printed parts on display at Fortify’s CAMX 2019 booth. CW photo | Heather Francis

The Innovation in Green Composite Design award went to LyondellBasell (Houston, Texas, U.S.) for its new styrene-free sheet molding compound (SMC) that meets the requirements of California’s Proposition 65 law, plus the LEED building quality standard for use of sustainable materials. Proposition 65 requires businesses to provide warnings to Californians about significant exposures to chemicals that cause cancer, birth defects or other reproductive harm.

The Infinite Possibility for Market Growth Award went to the University of Delaware (Newark, Del., U.S.) for the development of its Tailorable Universal Feedstock for Forming (TUFF), a short-fiber composite material engineered for the fabrication of complex-geometry parts.

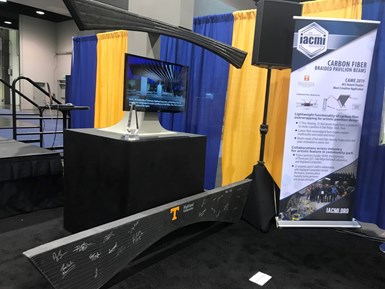

A demonstrator of the University of Tennessee's braided, arched beams on display at CAMX 2019. CW photo

The Fibers and Composites Manufacturing Facility (FCMF) at the University of Tennessee (Knoxville, Tenn., U.S.) was awarded the Most Creative Application award for its braided, arched beams developed for the International Friendship Bell pavilion in Oak Bridge, Tennessee.

The winner of the Equipment and Tooling Innovation award was Fortify (Boston, Mass., U.S.), for its development of a stereolithography 3D printing technology that can magnetically align fibers in a finished composite part.

The Material and Process Innovation award was given to aircraft Tier 1 fabricator Spirit AeroSystems (Wichita, Kan., U.S.) for its development of the Advanced Structures Technology & Revolutionary Architecture (ASTRA) demonstrator, a next-generation aircraft fuselage panel that Spirit says can meet the strength, throughput and cost requirements of a single-aisle commercial aircraft.

Related Content

TPC, FRP poles and fire-retardant panels

CAMX 2025: Avient Corp. is bringing its latest composites innovations including Polystrand, GridCore and Hammerhead solutions.

Read MoreAutomated RTM, SQRTM enhance aerospace composites serial production transition

CAMX 2025: Coexpair, in partnership with Radius Engineering, combines equipment development and fabrication with engineering of composite parts, demonstrated in its European customer support, deliveries.

Read MoreVIDEO: Recycling and machining carbon fiber scraps

Elevated Materials has partnered with Toray Composite Materials America, Inc. to collect and upcycle reclaimed carbon fiber scraps into large billet laminates, which can then be cut into various parts using CNC mills.

Read MoreNew brand identity launch aligns with nonwoven portfolio offerings

CAMX 2024: James Cropper, formerly known as Technical Fibre Products, is bringing its new name to the U.S. composites industry, highlighting its specialization in carrier, surface and fire protection veils, among other products.

Read MoreRead Next

From PMCs to sandwich composites: Tracing the path of test method standardization

Over the decades, progression of PMC and sandwich composite test method development and standardization has been shaped by the requirements of the composites industry.

Read MoreRobotic computed laminography brings X-ray CT resolution to large composite structures

Omni NDE collaborative robots, X-ray end effectors and Voxray’s reconstruction approach enables 5-micron inspection of aerospace parts without size constraints.

Read MoreCutting engine weight via thermoplastic composite guide vanes

Greene Tweed replaces metal stator vanes with its DLF material co-molded with a metal leading edge that meets performance, cost and high-rate production targets while cutting 4 kg per engine.

Read More