RTM

MVP launches Fast Flow LRTM process to speed closed mold part production

Increasing part production by decreasing injection times, Fast Flow LRTM is said to be capable of injecting a 50 square foot part in under four minutes using only one injection port.

Read MoreRevisiting the Fundamentals of Light Resin Transfer Molding (LRTM)

Like other closed molding composites processes, Light Resin Transfer Molding (LRTM) offers reduced waste and emissions, efficient materials use and a consistent and repeatable process. But LRTM requires less costly tooling and can still provide excellent cosmetics on both sides of a part in an efficient manufacturing process.

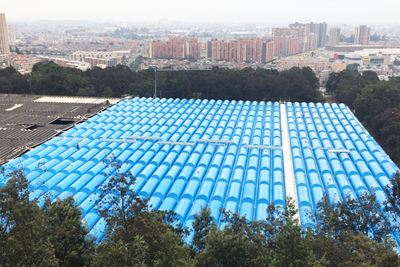

Read MoreSoling, Magnum Venus Products partnership produces LRTM composite domes

Incorporating the LRTM process enabled Soling to produce the largest LRTM part by volume manufactured in Colombia.

Read MoreTeijin Ltd. Tenax carbon fiber qualified for Airbus A320neo

Tenax dry reinforcements non-crimp fabrics and braided fibers will form the skins and stiffeners via automated RTM.

Read MoreWebinar presentation: Next-Generation Composites Materials and Processes (July 2020)

CompositesWorld hosted on July 28, 2020, a webinar titled, “Next-Generation Composite Materials and Processes.” If you missed the live webinar, you can watch the recording or download a PDF of the presentation.

Read MoreLeonardo and CETMA: disrupting composites for lower cost and environmental impact

Italian OEM and tier supplier Leonardo works with CETMA R&D to develop new composite materials, machines and processes, including induction welding for in-situ consolidation of thermoplastic composites.

Read MoreComposites 4.0: Digital transformation, adaptive production, new paradigms

An evolving landscape of automation, sensors and AI software is not an end, but a means to achieve the cost, quality, efficiency and agility required for future manufacturing.

Read MoreAimplas-led project develops thermoplastic prototypes

The RECONTRANS project adapts Arkema’s Elium thermoplastic resin for car, truck and rail applications.

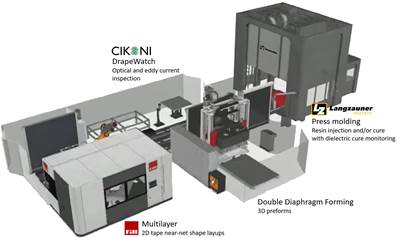

Read MoreHigh-rate, automated aerospace RTM line delivers next-gen spoilers

At Spirit AeroSystem’s Prestwick facility in Scotland, a glimpse of the future of aerocomposites manufacturing in a resin transfer molding line for A320 spoilers.

Read MoreSwinburne University and CSIRO's Industry 4.0 Testlab for Composite Additive Manufacturing

Australia and Germany collaborate to build Composites 4.0 production line for competitive advantage in next-gen manufacturing and workforce.

Watch

.jpg;maxWidth=300;quality=90)