BMI

Kaneka, Janicki reveal study results for TP2230 BMI tooling prepreg

Lowering cure temperatures without compromising durability, Kaneka Aerospace BMI prepreg TP2230 offers aerospace manufacturers a pathway to reduce tooling costs and lead times while maintaining high-temperature capability.

Read MoreLow-temp demold BMI prepreg enables low-cost master molds

CAMX 2025: Kaneka Aerospace 250°F BMI prepreg tooling, developed in collaboration with Janicki Industries, elevates composite tooling capabilities.

Read MoreSyensqo composites demonstrate titanium replacement on Boeing MQ-25 Stingray

Validation of integrating Cycom 5250-4HT prepreg into the UAV’s exhaust nozzle structure underpins the material system’s use in other high-temperature aerospace applications.

Read MoreHexcel introduces mid-temp Flex-Core HRH-302 honeycomb core

Bismaleimide (BMI) option to serve complex curvatures and thermal management needs of military, commercial and UAM aircraft.

Read MoreCAMX 2022 exhibit preview: Current Inc.

Current Inc. produces thermoset-based products such as tubing rods, sheets and more with high electrical and mechanical characteristics and different color combinations.

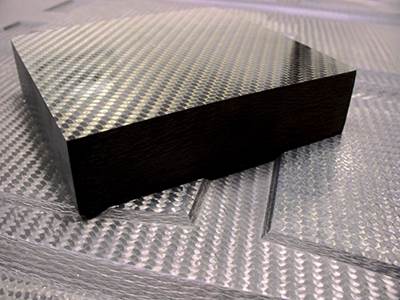

Read MoreMaterials & Processes: Tooling for composites

Composite parts are formed in molds, also known as tools. Tools can be made from virtually any material. The material type, shape and complexity depend upon the part and length of production run. Here's a short summary of the issues involved in electing and making tools.

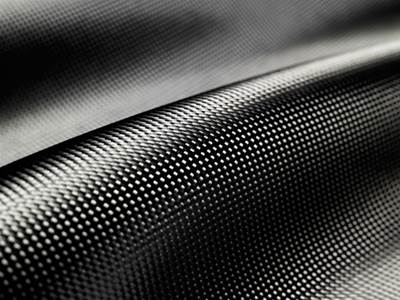

Read MoreMaterials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

Read MoreMaterials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

Read MoreThe making of carbon fiber

A look at the process by which precursor becomes carbon fiber through a careful (and mostly proprietary) manipulation of temperature and tension.

Read MoreMaterials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

Read More