Elastomer reusable vacuum bags address traditional material limitations

CAMX 2023: Sprayomer Technology Amor-Vac RVBs, distributed by Technology Marketing, are said to be more efficient, sustainable, long-living and lighter in weight compared to sprayable silicone or nylon film alternatives.

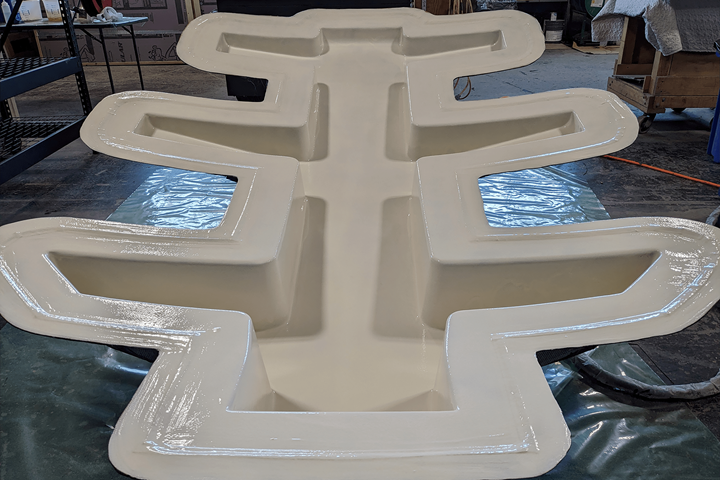

Distributor Technology Marketing Inc. (TMI, Salt Lake City, Utah, U.S.) supplies Sprayomer Technology Amor-Vac elastomer reusable vacuum bags (RVBs), bio-based elastomer materials that provide a variety of advantages compared to traditional sprayable silicone RVBs employed in composites manufacturing.

Sprayomer Technology Armor-Vac elastomer RVBs are suggested to work better than sprayable silicone RVBs and have an extended useful life beyond silicone when used with epoxy resins and prepreg systems. Moreover, when compared to silicone, this solution is said to be up to 80% lighter in weight, which could have positive effectives on process efficiency.

Elastomer RVBS can reportedly be manufactured in seamless near-net shape, tailored to a mold tool of any size. This enhances labor efficiency with rapid fitment and sealing of the bag while reducing the need for excess material and adjustments typically associated with conventional nylon-type tape down film bags. They are also a cleaner method of processing with fewer issues of concern related to cross-contamination and tracing in the manufacturing environment, and offer a lower carbon footprint than any other consumable film or reusable RVB, which can be an important consideration for environmentally conscious manufacturing practices.

TMI supports and excels technology and material with custom debulk table systems which accommodate flat stretchy elastomer bags and/or near-net shape bags on the same table system with quick and efficient processing. Debulk and or cure table systems can also be heated.

Related Content

-

Ceramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

-

Melker of Sweden accomplishes sea kayak with 100% sustainable composite construction

Built with ampliTex flax fabrics, a solid cork core and Sicomin plant-based resins, the company’s Värmdö kayak model highlights an environmentally conscious design for paddlers of all levels.

-

Low-cost, efficient CFRP anisogrid lattice structures

CIRA uses patented parallel winding, dry fiber, silicone tooling and resin infusion to cut labor for lightweight, heavily loaded space applications.