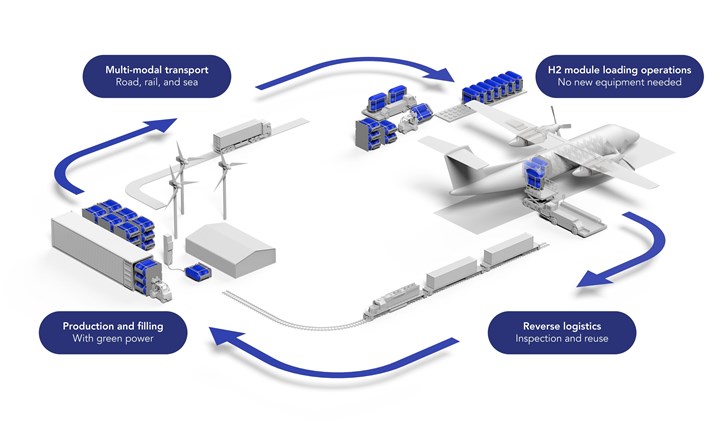

Universal Hydrogen’s twin-tank module uses carbon fiber-wrapped pressure vessels to store H2 gas at 850 bar, enabling a 400-nm range for a Dash 8 or ATR turboprop as well as easy transport and loading using existing infrastructure. Photo Credit: Universal Hydrogen

Hydrogen as a CO2-free alternative to fossil fuels has been on the horizon for decades, and growth in carbon fiber-reinforced plastic (CFRP) pressure vessels for hydrogen storage has definitely been on the rise. But in 2020, hydrogen became a mandate, identified by the European Commission (EC) as a key priority to achieve the European Green Deal for a sustainable economy and climate-neutral EU by 2050. Key events for hydrogen in aviation include:

- May 2020 — Clean Sky 2 and The Fuel Cells and Hydrogen Joint Undertaking (FCH JU) published “Hydrogen-powered aviation,” detailing how short-range (85-165 passenger) hydrogen-powered aircraft could achieve entry into service (EIS) by 2030-2035.

- June 2020 — France’s $17 billion pandemic relief program is tied to goals from the “Hydrogen-powered aviation” report; Air France says it will cut CO2 emissions in half for domestic flights by 2024.

- July 2020 — EC publishes “A hydrogen strategy for a climate-neutral Europe,” calling for a €65 billion investment for hydrogen transport, distribution, storage and refueling stations, listing support policies and funding mechanisms including the Clean Hydrogen Partnership and ETS Innovation Fund (€10 billion during 2020-2030).

- July 2020 — Airbus CEO Guillaume Faury, in an interview with Aviation Week editor Graham Warwick, commits to the first decarbonized aircraft EIS by 2035; he forecasts program launch by 2027-28 and maturation of necessary technologies by 2025.

- July 2020 — ZeroAvia (Hollister, Calif., U.S.) completes test flight of single-engine, six-seat Piper aircraft modified to use compressed hydrogen (H2) gas and unveils U.S.-based flight testing for a similarly modified twin-turboprop, 19-seat Dornier Do 228 per its roadmap to certify a 20-seat, H2-powered aircraft with 500-mile range by 2023.

- August 2020 — Universal Hydrogen (Los Angeles, Calif., U.S.) announces twin tank modules for a 50-seat aircraft (see photo), plus refueling logistics and infrastructure for regional airlines/operators to be commercial by 2024.

Hydrogen’s viability as a fuel source — regardless of industry — depends on rapid development of a variety of transport, delivery and storage technologies that are young but fast-evolving. Commercializing these technologies will not be simple, but they are being addressed. Below is a summary of some work being done.

Universal Hydrogen

Co-founded in 2020 by Paul Eremenko, ex-CTO for Airbus SE (Leiden, Netherlands) and United Technologies Corp. (Farmington, Conn., U.S.), Universal Hydrogen’s goal is to help transition to hydrogen-powered aviation by providing a hydrogen fueling infrastructure. One key component is its fuel module comprising twin H2 storage tanks in a carbon fiber-reinforced polymer (CFRP) frame. “We will supply the modules to site as needed, so there's no need for hydrogen storage infrastructure,” explains Universal Hydrogen CTO J.P. Clarke. “The modules are simply loaded into the plane like a battery or galley supplies.”

Photo Credit: Universal Hydrogen

Modules have been developed first for the 50-seat Dash 8 and ATR turboprop regional aircraft. These modules will feature 7-foot long by 3-foot-diameter tanks, using either carbon fiber to hold H2 gas at 850 bar achieving a density of 50 kg/m3, or insulated metal tanks to hold liquid H2 (LH2) at standard pressure and temperature achieving a 71 kg/m3 density. Though the LH2 tanks offer higher volumetric efficiency, the insulated but uncooled tanks must be used within 42 hours because LH2 vaporizes if not kept at -253°C. “Both type tanks will sit within a lightweight, structurally-optimized composite frame that also lends impact resistance and some load-bearing capabilities,” says Clarke.

The H2 gas tanks will include an impermeable polymer liner wrapped with layers of dry carbon fiber braid and a Kevlar aramid fiber protective outer layer. “There is no need for resin,” Clarke explains. “The liner addresses permeability, while the carbon handles the hoop and axial loads and the outer layer plus frame prevents damage; thus weight and thickness are reduced. This integrated tank and frame design, when combined with the mapping of functions to each of the tank layers, has allowed us to get some significant improvements in the mass fraction.”

Mass fraction is calculated by dividing the mass of the stored hydrogen mass by that of the whole module, thus the larger the mass fraction, the better. “We did a very extensive trade study looking at the mass fraction and volumetric efficiency in the context of the Dash 8 and ATR aircraft,” Clarke notes. “So, you’re looking at volume and weight of fuel versus what can fit in these aircraft, achievable range and maximum takeoff weight, weight distribution, etc. With H2 gas at 850 bar, we can fly about 400 nautical miles with a 45-minute reserve and about 550 nautical miles with the LH2 tanks. However, the average stage length for a turboprop mission is around 300 nautical miles, so the vast majority of these flights can be done with a gaseous H2 system using CFRP tanks.”

Will Universal Hydrogen partner with a composite tank manufacturer? “Our strategy is to partner where it makes sense and stick to our core business,” says Clarke. He reiterates Universal Hydrogen’s focus: “We want to be the provider of the fuel and the infrastructure. We'll provide the modules, and we'll get them to where they’re needed so that our partners can focus on the rest of the aircraft design and operation. Our goal is to be an enabler of hydrogen-powered aviation.”

SpaceTech4Sea

Like aviation, shipping is also coming under regulations designed to reduce CO2 and other greenhouse gas (GHG) emissions. From January 2018, ships of more than 5,000 gross tons loading or unloading cargo or passengers at ports in the European Economic Area (EEA) must monitor and report their CO2 emissions. Even further, as part of its MARPOL convention to reduce pollution from ships, the International Maritime Organization (IMO) has mandated from January 2020 that sulfur in fuel oil must be reduced from 3.50% m/m (mass by mass) to 0.50%. The IMO has also committed to an initial GHG strategy to pursue a 50% reduction by 2050 compared to 2008 levels.

“The best possibility to be in compliance is to initially shift to liquid natural gas (LNG),” says Dr. Panayotis Zacharioudakis, managing director of Ocean Finance (Athens, Greece), an advisory firm advancing maritime sustainability and coordinator of the EC projects SuperGreen and SpaceTech4Sea. SuperGreen will create a sustainable and green transport system in Greece comprising electric commuter vessels and two hybrid LNG/electric catamarans that will connect the port of Piraeus with other ports in the eastern Mediterranean network. “For this project, we are building a high-speed ferry in CFRP,” explains Zacharioudakis. “If we used a state-of-the-art metal LNG tank, it would weigh seven metric tons, which equates to a little more than 70 passengers [100 kilograms per person with baggage]. So, we’d have to decrease the passenger capacity by 70.”

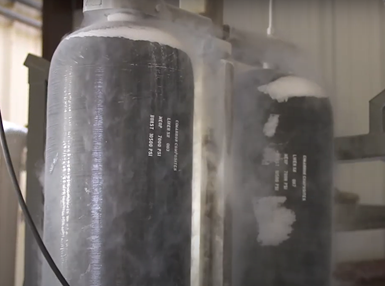

Cimarron Composites performs cryogenic testing on CFRP pressure vessels. Photo Credit: Cimarron Composites

Why the extra weight? “Compared to diesel, LNG must be stored at a cryogenic -163°C and the metal tanks must use materials, construction, insulation and operating systems that meet the IMO’s requirements for gaseous fuels, or IGF code,” says Zacharioudakis. For Ocean Finance, the extra weight was not acceptable, so it began researching possible solutions and found a report about cryotanks Cimarron Composites (Huntsville, Ala., U.S.) developed with NASA.

“This is when we began the EASME (European Agency for SMEs) SpaceTech4Sea project,” says Zacharioudakis. “The idea is to modify aerospace technology for maritime applications.” The third project partner is classification society American Bureau of Shipping (ABS, Houston, Tex., U.S.), which will validate and qualify the technology. In September 2019, ABS granted approval in principle (AIP) for Cimarron’s conceptual design of an ultralight, cryo-capable composite LNG tank. Since then, it has built and tested sub- and full-scale tanks for certification. “They just finished the last testing,” says Zacharioudakis. “In a little more than two months, we will have a full certification for composite LNG tanks for the marine market. This tank will provide weight savings of more than 85% versus a conventional metal tank.”

Though most of the tank’s specifics are proprietary, Cimarron Composites founder and president Tom DeLay says it is made with carbon fiber and an advanced thermoset resin using some resin infusion and wet filament winding. “We have tested 25-inch- and 40-inch-diameter tanks and are talking to the CFRP ferry builder for SuperGreen about tanks with a capacity of five cubic meters [5,000 liters], which could be achieved with a tank 2 meters in diameter and 2.5 meters long.” Ocean Finance sees a market for more than a thousand such tanks and will work with Cimarron to establish automated production, possibly in Greece.

And what about hydrogen? “Even while we finish these LNG projects, we have started to look at hydrogen,” notes Zacharioudakis. “There is so much interest, activity and now funding available in Europe. One issue, however, is that maritime regulations specify tanks must provide a holding time of up to 15 days for LNG. This will be the same for LH2.” DeLay concedes that developing a cryo-capable tank for LH2 (-253ºC, see above) is much more difficult than developing a cryo-capable tank for LNG (-196ºC); among the challenges is to find materials that can resist embrittlement and cracking. He is working now with Ocean Finance to help complete a trade study, looking at the technical and economic factors of using liquid versus gaseous H2 for marine vessels.

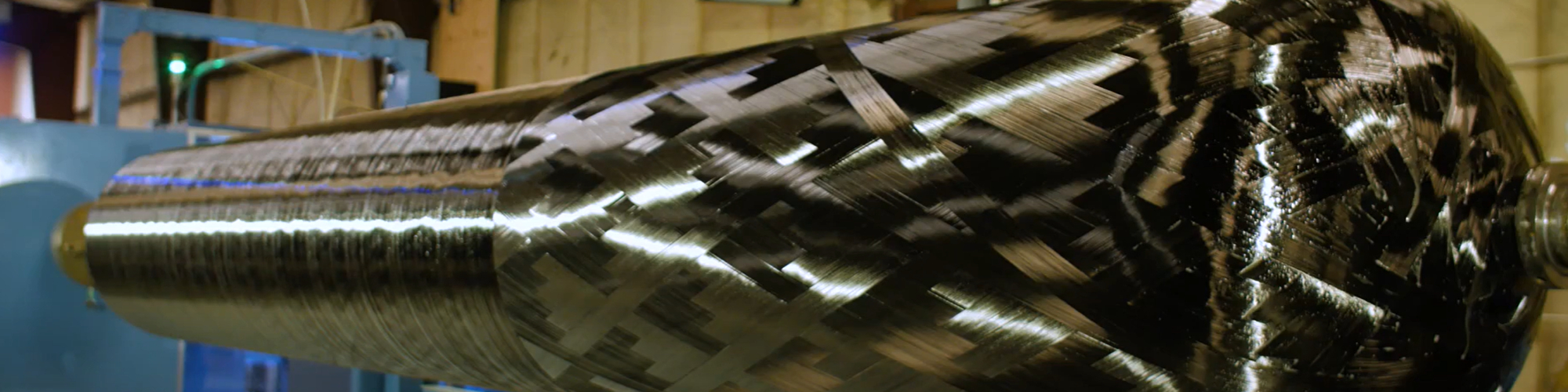

Filament winding of a Jupiter Type IV CFRP pressure vessel. Photo Credit: Cimarron Composites

Neptune tanks for H2 gas

Notably, Cimarron Composites has already developed a Type IV CFRP tank for high-pressure storage of hydrogen and other gases. “Our original Jupiter tank was developed for the transport of most industrial gases, including hydrogen, at a pressure of 4,350 psi [300 bar],” says DeLay. “Hydrogen, however, is transported more effectively at higher pressures, which is why we developed the 7,500 psi [517 bar] Neptune tank.”

H2 gas transport by road, rail or sea

Neptune high-pressure (517 bar) CFRP tanks enable transporting 600 kg of H2 gas in a standard 20-ft container. Photo Credit: Cimarron Composites

Both Jupiter and Neptune tanks have passed the myriad tests per UN ISO 11515 requirements and are available in a range of diameters and lengths up to 26 feet. “These tanks were developed for shipping in standard modules by truck, rail or ship,” notes Delay. “We have found that a 30-inch diameter has an ideal packing efficiency, allowing us to haul more hydrogen than with larger-diameter cylinders. With a 19-foot length, we can fit nine tanks into a standard 20-foot container. At 67 kilograms of hydrogen gas per tank, we can move 600 kilograms in a 20-foot container and 1,200 kilograms in a standard 40-foot container.”

“We buy carbon fiber from all of the main suppliers, including Toray [Tokyo, Japan], Mitsubishi Rayon [Tokyo], Teijin [Rockwood, Tenn., U.S.] and Hyosung [Seoul, South Korea],” adds DeLay, “but for Neptune we have qualified with three different suppliers simultaneously. We formulate the resin ourselves using commercially available products and very tightly control the fiber and resin content as well as the tension during filament winding and oven cure cycle to prevent thermal stress. All of this adds to the mechanical performance of the tanks.”

Regardless of whether the need is for cryogenic liquid storage or high-pressure gas storage, DeLay sees the opportunities growing. “It has taken us years to develop our expertise,” he says, “starting from fuel tanks for rockets to the large storage and transport tanks we’re developing and producing now. A year ago, I was skeptical about hydrogen, thinking the only reason for it was a push by the government. But now we are getting very large orders and all kinds of requests. We can see that, globally, a wide range of industries are investing seriously in hydrogen and governments are supporting this development. It looks like we’re ready with the right products at the right time.”

This article was originally published 10/23/2020, updated 7/11/2022

Related Content

Cycling forward with bike frame materials and processes

Fine-tuning of conventional materials and processes characterizes today’s CFRP bicycle frame manufacturing, whether in the large factories of Asia or at reshored facilities in North America and Europe. Thermoplastic resins and automated processes are on the horizon, though likely years away from high-volume production levels.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreRead Next

Hexagon Purus to produce high-performance composite pressure vessels

The subsidary of Hexagon Composites has been awarded a contract to design, develop, qualify and produce for a new major aerospace company.

Read MoreIACMI collaboration aims to develop carbon fiber for hydrogen storage tanks

The $2.7 million U.S. Department of Energy funding supports the vision for affordable hydrogen production, storage distribution and use.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read More

.jpg;maxWidth=300;quality=90)