Axiom prepregs target pressure vessels

Axiom Materials has launched two new narrow prepreg products developed for use in pressure vessels to store compressed natural gas (CNG) and hydrogen for e-mobility applications.

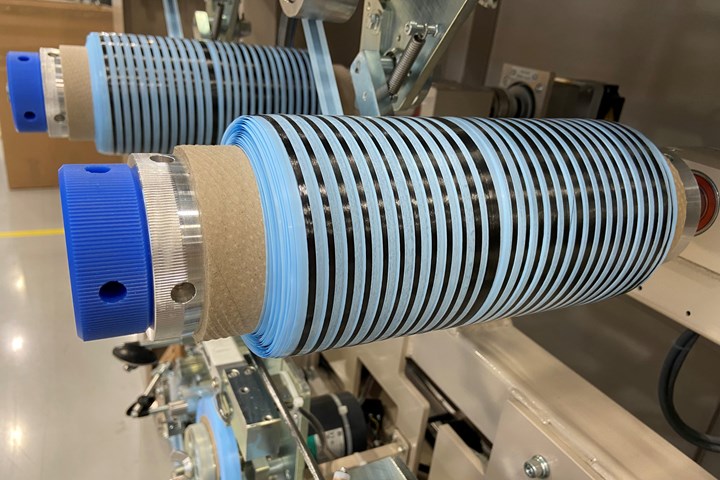

Axiom’s narrow prepreg is offered with cyanate ester or epoxy resin matrix. Photo Credit: Axiom

Axiom Materials (Santa Ana, Calif., U.S.), a subsidiary of Kordsa (Istanbul, Turkey), has launched two new narrow prepreg products developed for use in pressure vessels to store compressed natural gas (CNG) and hydrogen for e-mobility applications. AX-6170 and AX-6201XL are designed for use in either automated fiber placement (AFP) machines or machine-supported winding techniques used in the fabrication of round, cylindrical, and rectangular vessels and structures. AX-6170-C-150GT700-0.25'' RC37 prepreg is a 0.25-inch, 150-gsm cyanate ester carbon fiber prepreg for critical strength parts that operate in high-temperature environments up to 600⁰F (316°C), such as lithium-ion battery containers. AX-6201XL-C-150GT700-0.25'' RC37 is a 0.25-inch, 150-gsm toughened epoxy carbon fiber prepreg designed for the manufacture of larger parts that require excellent surface quality. Both prepregs can be cured via vacuum bag oven or autoclave processes. The product is also available in a flame-retardant variant. Primary uses are large structural parts and pressure vessels for compressed nitrogen gas (CNG) and hydrogen fuel tanks for vehicles. The resin systems were designed by Axiom Materials and will also be manufactured in Turkey at Kordsa’s Composite Technologies Center of Excellence.

Related Content

-

Carbon fiber in pressure vessels for hydrogen

The emerging H2 economy drives tank development for aircraft, ships and gas transport.

-

Materials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

-

Materials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.