Addcomposites path-planning, simulation and defect detection platform for AFP

Purpose-built OLP software platform, AddPath, now supports multiple AFP tools, enabling end users to use their own existing hardware.

Photo Credit: Addcomposites

Addcomposite’s (Espoo, Finland) AddPath platform, a purpose-built OLP software, now supports multiple automated fiber placement (AFP) tools, enabling end users to use their own existing hardware. Addcomposites says it is developing and providing AddPath for a range of third-party AFP systems; currently it supports two commercial AFP systems and three independent academia developed AFP tools.

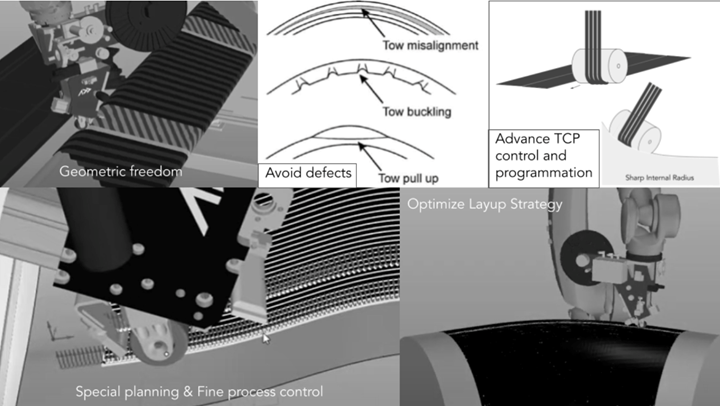

According to the company, the AddPath platform unleashes the capabilities of the AFP process. Offering geometric freedom features, it can perform 2D layups, closed shapes (traditional AFP or tape winding methods) import stress paths, create or plan selective area patches or passes to add localized strength and more. Customized details, such as trimming, redrawing, flipping or suppressing individual passes are possible.

Additional key features include:

- Fine process control: Manipulate tool orientation at any point to address special geometric constraints, avoid collisions, control the heat profile and compaction force and achieve in-situ consolidation.

- Defect detection: Analyze the planned passes for fiber waviness, gaps, overlaps and ply drops, then edit individual points for a high-quality result.

- Sustainable manufacturing: Optimize layup strategies for minimal material and time usage by choosing approach, retract and other tool motion parameters.

- Virtual production: Create complete virtualized production simulations, visualize every step of the simulated motion or run a collision/singularities analysis to identify troubled areas.

- FEA software interoperability: Provide an FEA-ready file that can be imported into commonly used FEA software to analyze a planned layup with material definitions.

- Program: Automate program generation for select robotic languages with advanced TCP controls, eliminate manual editing.

- Automate changes: Edit program post-processor for specific geometry, material in a programmed manner to avoid editing small tweaks for each specific project.

- Visualize data: Import and organize captured process data into AddPath, creating insightful visualizations to correct programmed parameters.

- Quality control: Generate quality control/assurance reports from the input and captured data, thermal images and other process data. Highlight anomalies in real time to notify the operator for correction.

- Artificial intelligence: AddPath can export captured data into a user’s own neural network platform in structured format to analyze the data and automate defect detection and further FEA validation.

To get started, users can fill out a process documentation form (30 min) and can receive a customized AddPath for their AFP tool and robot within a few days.

Related Content

-

Nine factors to consider when designing composites cure tooling

Gary Bond discusses the common pitfalls and compromises when designing good cure tooling and their holistic significance for a robust composite production process.

-

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

-

CFRTP upper stage propellant tank

PROCOMP uses in-situ consolidation AFP and ultrasonic welding to demonstrate lightweight, novel tank design.

.jpg;maxWidth=300;quality=90)