Winners for 2020 Award for Composites Excellence (ACE) announced

The 2020 Awards for Composites Excellence (ACE) recognized the University of Tennessee, TRB Lightweight Structures, University of Delaware, IYRS School of Technology and LyondellBasell for outstanding achievement and innovation.

For the Design category, the Most Creative Application Award went to the University of Tennessee for UTK Filament Tower. Photo Credit: ACMA

On Sept. 24 the American Composites Manufacturers Association (ACMA; Arlington, Virg., U.S.) announced the winners for the Awards for Composites Excellence (ACE) sponsored by Composites One (Arlington Heights, Ill., U.S.). According to the ACMA, the ACE is a prestigious composites industry competition that recognizes outstanding achievement and innovation in design, manufacturing and market growth. The winning entries were announced virtually at the seventh annual Composites and Advanced Materials Expo (CAMX).

Each category with its designated winner is categorized below.

Design

In the Design category, the Most Creative Application Award went to the University of Tennessee for UTK Filament Tower.

The UTK filament tower was the first composite structure featured at Exhibit Columbus (Columbus, Ohio, U.S.), a biennial event where designers create outdoor installations and experiences. A team of 23 students, faculty and staff used a nine-axis robot and a novel coreless filament winding technique, which eliminated the need for a surface mold, to construct the 30-foot lattice tower. It featured 3D-printed composite bases and 27 composite components, each weighing between 5-30 pounds. and measuring 3-8 feet in length. The project explored computational design and robotic fabrication of composite structures for architectural applications, highlighting the aesthetic qualities of carbon and glass fiber.

Manufacturing

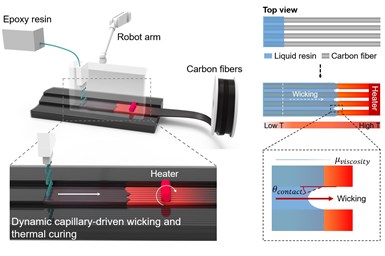

In the Manufacturing category, the Equipment and Tooling Innovation Award went to the University of Delaware for 3D Printing Continuous Carbon Fiber/Thermoset Composites.

The University of Delaware won in the Manufacturing category for its LITA 3D printing system.Photo Credit: University of Delaware

The University of Delaware Composite and Additive Manufacturing (CAM) Laboratory has developed a localized in-plane thermal assisted (LITA) 3D printing technique to fabricate continuous fiber-reinforced thermoset composite parts. The 3D printing technique is based on a robotic system consisting of printing head, liquid thermoset resin dispenser and heater. This 3D printing technique allows thermoset polymer liquid with a controllable viscosity and degree of curing to enable its fast and near-simultaneous infusion and curing to implement in-situ solidification of composites into arbitrary shapes. A wide range of thermoset polymers and fibers (e.g., carbon, glass and Kevlar) could be applied.

The Manufacturing category also features the Materials and Process Innovation Award which went to TRB Lightweight Structures Ltd. (Huntingdon, U.K.) for Fast Press Cure, A Disruptive High Volume Composite Manufacturing Method..

TRB has developed a fully automated and vertically integrated process to unlock composites at scale. Photo Credit: ACMA

TRB has developed a fully automated and vertically integrated process to unlock composites at scale, resulting in the manufacture of complex components in a fraction of the time of traditional hand layup. It works with carbon fiber, glass, hemp and other composite fiber materials and can incorporate EMI shielding, thermal insulation, high voltage insulation in the layup process, to enable the right material mix and structure for a wide variety of components. This innovation means that for the first time, composites can meet the cost, velocity and quality requirements of the electric.

Market Growth

In the Market Growth category, the Composites Sustainability for Market Growth Award went to LyondellBasell (Houston, Tex., U.S.) for Composite Manhole Covers Solve Iron Problems.

LyondellBasell and Composite Access Products (CAP) collaborated to replace traditional materials like metal and concrete used in manhole applications with composites. Photo Credit: ACMA

With rising construction activities worldwide, the manhole cover market is expanding. Through the collaboration between LyondellBasell and Composite Access Products (CAP; McAllen Tex., U.S.), composite solutions are replacing traditional materials like metal and concrete used in manhole applications due to its superior properties like strength, corrosion resistance and molding capabilities. Through CAP’s compression molding process of LyondellBasell’s thermoset material, cost improvements and rapid production cycles are realized when compared to resin transfer molding (RTM) and other fiberglass (FRP/GRP) casting processes. This process enhances quality by reducing entrapped gas, ensuring a complete thermoset polymer cure, delivering fully impregnated fiberglass and eliminating many post-process operations.

Finally, in the Market Growth category, the Infinite Possibility for Market Growth Award went to the IYRS School of Technology (Newport, R.I., U.S.) for Heavy Lift Aerial Platform (HLAP).

The Heavy Lift Aerial Platform (HLAP) concept model has a range of applications from urban air mobility, commercial or military, including delivery of goods, observation, inspections, communications, search and rescue or cinematography. This multi-purpose unmanned aerial vehicle features a 29-pound primary airframe with an all-up flying weight of 61 pounds. The eight power units produce a load capacity of 103 pounds. The array of processes employed include: Direct tool CNC machining, prepreg fabrication, vacuum infusion, 3D printing and hollow form braiding. The three-year project has involved multiple generations of IYRS students engaged in CAD modeling, CNC operations and fabrication of various platform components.

IYRS School of Technology wins Market Growth category for the Heavy Lift Aerial Platform (HLAP) concept model. Photo Credit: ACMA

Related Content

Aerospace manufacturing innovations demonstrate the future of aerocomposites

CAMX 2025: Attendees are able to explore several of NIAR ATLAS’ prototype developments in person, highlighting tool-less space manufacturing, AI-enabled inspection and repair and thermoplastic overmolding.

Read MorePrecision composite formatting solutions enable customer success

CAMX 2025: Web Industries spotlights its wide experience in material versatility and contract manufacturing services, including converting and supply chain solutions for aerospace, space, satellite, oil and gas, automotive and energy sectors.

Read MoreFall events chart the course for composites

A busy fall brings industry-leading events and recognition for operations setting new benchmarks for excellence.

Read MoreNoncontact optical strain gage delivers complete 3D surface measurement insight

CAMX 2025: The Aramis system by Trilion, based on DIC and photogrammetry technology, performs high-precision measurements in the sub-micrometer range, across a wide range of testing environments and material types.

Read MoreRead Next

Thermoplastic composite materials and processing interactions

Selection of product material formats and their interactions with various process methods heavily influence a final TPC part’s properties and fabrication options.

Read MoreRobotic computed laminography brings X-ray CT resolution to large composite structures

Omni NDE collaborative robots, X-ray end effectors and Voxray’s reconstruction approach enables 5-micron inspection of aerospace parts without size constraints.

Read MoreComposite trends gaining industrial traction for 2026

Startups & Investors topics over the last year show the industry is rapidly gaining maturity while benefiting from macro-trends in circularity, AI and TPC and high-rate manufacturing, all potential gains for investors.

Read More