Teijin carbon fiber-reinforced thermoplastics qualified for aerospace applications

Collins Aerospace deemed Teijin Ltd.’s Tenax thermoplastic woven fabric and consolidated laminate materials suitable for large-scale production of structural components.

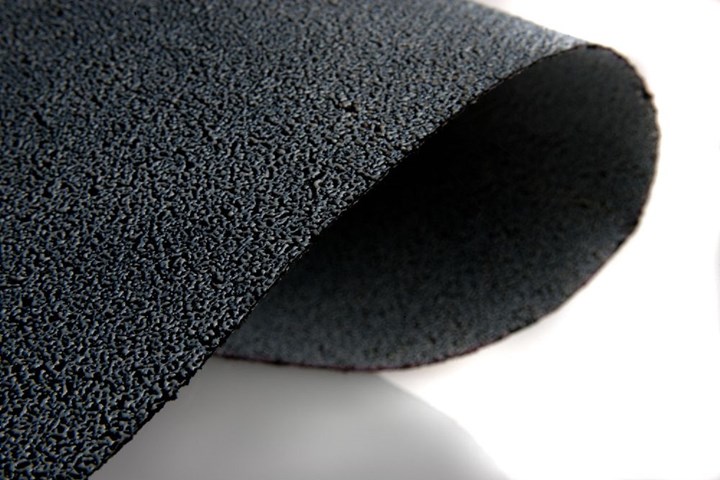

Tenax ThermoPlastic Woven Fabric (TPWF). Photo Credit: Teijin Ltd.

Teijin Ltd. (Tokyo, Japan) announced on Oct. 9 that it has qualified its carbon fiber-based materials Tenax ThermoPlastic Woven Fabric (TPWF) and Tenax ThermoPlastic Consolidated Laminate (TPCL) by Collins Aerospace (Cedar Rapids, Iowa, U.S.), a unit of Raytheon Technologies Corp. (Waltham, Mass., U.S.).

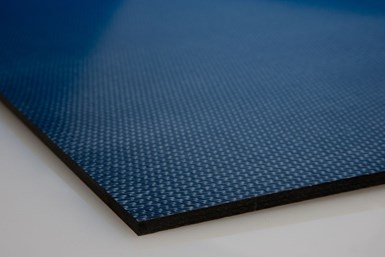

According to Teijin, Tenax TPWF is a woven carbon fiber fabric coated with a thermoplastic polymer and Tenax TPCL are completely impregnated and consolidated sheets made of several layers of Tenax TPWF.

The qualified product is based on woven high-strength carbon fiber and polyetheretherketone (PEEK) polymer, which achieves high heat, impact and fatigue resistance, helps to reduce production costs and improve component manufacturing efficiency as a result of the potential of a rapid molding process. Teijin notes that the material is suited for large-scale production of parts combined with high mechanical performance, such as structural components for aerospace.

Tenax ThermoPlastic Consolidated Laminate (TPCL). Photo Credit: Teijin Ltd.

Teijin adds it has an existing strong business relationship with Collins Aerospace. As a proof, the company points to a facility of Teijin Carbon America, Inc., the company’s core carbon fiber business in the U.S., which was awarded Supplier Gold as the only fiber manufacturer worldwide for the supply of an oxidized PAN fiber (OPF) Pyromex for aircraft brake-friction materials.

As one strategic focus of its medium-term management plan for 2020-2022. Teijin is intensively accelerating its development of mid- to downstream applications for aircraft, such as cost-effective carbon fibers with higher-tenacity and higher-tensile modulus, intermediate materials including Tenax Dry Reinforcement carbon fiber materials (Tenax DR), carbon fiber thermoplastic unidirectional pre-impregnated tape (Tenax TPUD), carbon fiber thermoplastic consolidated laminate (Tenax TPCL) and thermoset prepreg. Going forward, Teijin intends to further strengthen its carbon fiber and its intermediate material business as a leading solution provider for aircraft applications, targeting annual sales in this field in excess of USD 900 million by around 2030.

Related Content

-

Cutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

-

Otto Aviation launches Phantom 3500 business jet with all-composite airframe from Leonardo

Promising 60% less fuel burn and 90% less emissions using SAF, the super-laminar flow design with windowless fuselage will be built using RTM in Florida facility with certification slated for 2030.

-

Automated robotic NDT enhances capabilities for composites

Kineco Kaman Composites India uses a bespoke Fill Accubot ultrasonic testing system to boost inspection efficiency and productivity.