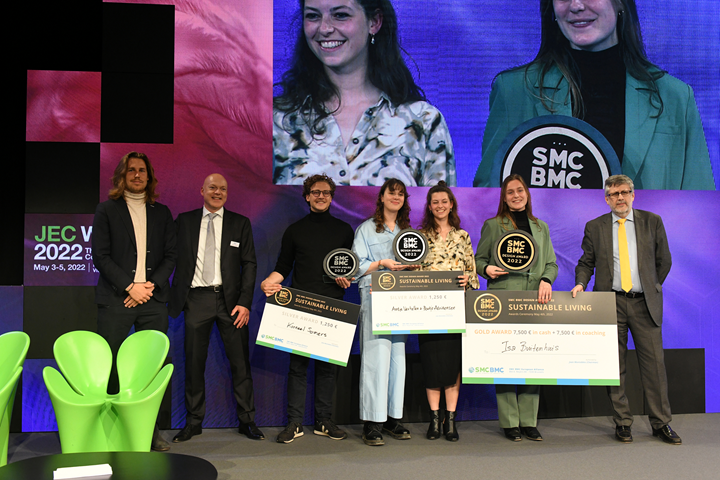

SMC BMC Design Award 2022 winners are revealed

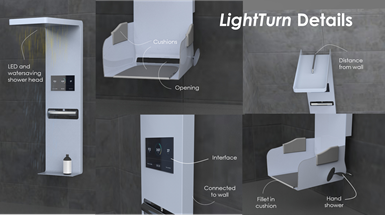

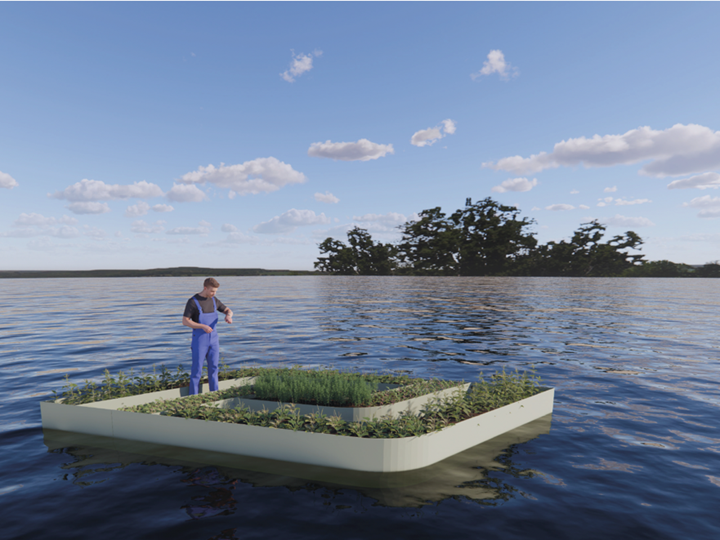

Gold and Silver awards include SMC LightTurn design for seated showering, an SMC floating platforms for sustainable, floating gardens and a BMC TileTurn Solar reflective sustainable roofing solution.

SMC BMC Awards 2022 Gold and Silver winners. Photo Credit, all images: JEC World 2022

Isa Buitenhuis (An industrial design student at Technical University Delft, Netherlands) has won the Gold Award of the SMC BMC Design Award 2022 launched by the European Alliance for SMC BMC (Brussels, Belgium). During the award ceremony at JEC World 2022, she presented the LightTurn, a new experience for seated showering targeted at elderly consumers, providing optimized ergonomics to the user, durability and low water usage.

The theme of this year’s edition of the SMC BMC Design Award was “Sustainable Living.” It is the third time the European Alliance for SMC BMC successfully organized the design competition. With the objective to find new applications for these versatile materials, students from design schools around Europe were invited to submit their projects. Each project was reviewed in detail by an independent Jury against key selection criteria: creativity, end-user functionality, sustainability and feasibility in SMC BMC.

The Jury consisted of expert members from both the design community and the composites industry:

- Joan Montobbio, Jury chairman, managing director of Menzolit Spain/ Menzolit UK, president of European Alliance for SMC BMC

- Joachim Froment, co-founder and creative director at FutureWave Design & Engineering

- Franck Glowacz, editor-in-chief of JEC Composites magazine

- Andrea Ratti, professor composites engineering and design, Politecnico (Milano, Italy)

- Hubertus Rehermann, retired from Daimler AG, responsible for SMC Manufacturing and Technology Center

The LightTurn design, comprised of sheet molding compound (SMC), combines a chair, shower head, interface and light system in one product. Traditional showering solutions for elderly consumers are said to be visually unattractive and do not fit well in a private living environment. Through using a modular design, parts can be exchanged over time enabling the initial shower tray to be converted into a seat. The integrated interactive display keeps track of showering time, hence minimizing water consumption.

“For me, it was great to participate in the SMC BMC Design Award, and I am truly excited to win,” Buitenhuis says. “It was a nice experience to learn more about SMC and to get the exposure to the composites world. I was a bit nervous at the award ceremony, but this prize makes me feel very happy and does make me forget all the long hours I invested in the project.”

According to Joan Montobbio, president of the SMC BMC Alliance and chairman of the jury, “the Jury thought that Isa’s design was highly creative and new, addressing true consumer needs. We thought the design was very complete and professionally presented, the solution durable and therefore sustainable, and moreover, we envision it is feasible in SMC and can be successfully commercialized.”

As winner of the SMC BMC Design Award Gold Award, Buitenhuis received a prize of €7,500 in cash. In addition, she will receive support from the European Alliance Members to fine-tune her design for improving functionality and manufacturing ability, with the objective to help successfully introduce the LightTurn into the market.

Two teams won the Silver Award, in addition to €1,250. Antje Verhellen and Boukje Adriaensen (design students at Thomas More in Mechelen, Belgium) designed Sea-weeds floating garden solutions, enabling growth of food in urban areas on lakes and sea shores, using available space in an efficient way. These are floating platforms made from multiple SMC components, with an integrated system for desalination of seawater and powered by solar heat.

TileTurn Solar.

Korneel Somers (an industrial design at TU Delft) designed the TileTurn Solar reflective sustainable roofing solutions. The bulk molding compound (BMC) roofing tiles in his design proposal can turn black or white, and thus reflect or absorb solar energy dependent on season and external temperature. This enables to optimize energy generation inside the house, minimizing natural gas consumption.

Please note that the intellectual property ownership of the designs submitted for the SMC BMC Design Award resides with the finalists.

Related Content

Exel Composites adopts bio-based UPR resin at commercial scale

Purchase of Polynt bio-based resin delivers 20% cut in CO2 footprint for composites manufacturers, builds Exel’s efforts to give customers more sustainable options.

Read MoreScaling up thermoplastic composites recycling

Thermoplastic composites are always said to be “recyclable.” Netherlands-based recycler Spiral RTC discusses the process, challenges, applications and opportunities to building a real recycling ecosystem.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreJEC World 2024 highlights: Glass fiber recycling, biocomposites and more

CW technical editor Hannah Mason discusses trends seen at this year’s JEC World trade show, including sustainability-focused technologies and commitments, the Paris Olympics amongst other topics.

Read MoreRead Next

From PMCs to sandwich composites: Tracing the path of test method standardization

Over the decades, progression of PMC and sandwich composite test method development and standardization has been shaped by the requirements of the composites industry.

Read MoreRobotic computed laminography brings X-ray CT resolution to large composite structures

Omni NDE collaborative robots, X-ray end effectors and Voxray’s reconstruction approach enables 5-micron inspection of aerospace parts without size constraints.

Read MoreCutting engine weight via thermoplastic composite guide vanes

Greene Tweed replaces metal stator vanes with its DLF material co-molded with a metal leading edge that meets performance, cost and high-rate production targets while cutting 4 kg per engine.

Read More