Optimizing machining for composites: Tool designs, processes and Industry 4.0 systems

Hufschmied moves beyond optimized milling and drilling tools to develop SonicShark inline quality control system and Cutting Edge World cloud platform for optimized tool use and processes.

Hufschmied Zerspanungssysteme (Bobingen, Germany) was founded in 1991 by Rudolf M. Hufschmied and his son, Ralph, as an industrial agency for technology products in the field of machining. Initially, designing his own tools was just a side project for mechanical engineer Ralph Hufschmied. This changed when an automotive customer had a problem with the production of a new type of airbag cover. Ralph found the right solution with a special tool geometry and a few trial tools turned into a major order. In 1998, the sports car — which owed its instrument panel to this tool development — conquered the market and the design of cutting tools for new materials became Hufschmied’s business model.

“A new world opened up for us when we realized how great the demand for machining solutions for plastics and fiber composites was. Composite materials were becoming increasingly important,” recalled Ralph at the company’s anniversary in 2021, referring to the aerospace and automotive industries as examples. Composites and other high-tech materials, he explained, “often had to be reworked by hand due to a lack of suitable machining solutions. Based on innovative cutting-edge geometries and coatings, we were able to offer solutions that solved the various problems faced by manufacturers in the best possible way. Tools for other problematic materials such as graphite or ceramics were gradually added.”

Start of production

From 1998 on, Hufschmied began to focus more and more on the construction and design of cutting tools for demanding materials such as fiber-reinforced composites and ceramics, with steadily growing success. After moving into a new facility in Bobingen in 2003, the company set up its own production facility just 2 years later with the acquisition of a tool grinding company.

In 2016, the company headquarters were expanded to include an engineering center for process optimization in customer projects. That same year, Hufschmied received the BMW Group’s Supplier Innovation Award for process optimization for the i3 and i8 models and contributions to the production of the Carbon Core body of the BMW 7 Series.

In 2018, Hufschmied added a tool development center equipped with the latest generation of high-precision 3D measuring devices to further strengthen research into quality factors in machining. In 2022, Hufschmied opened a second production site in Sigmaringen. Today, Hufschmied employs around 130 people and has subsidiaries and sales partnerships worldwide.

Tool design optimized for composites

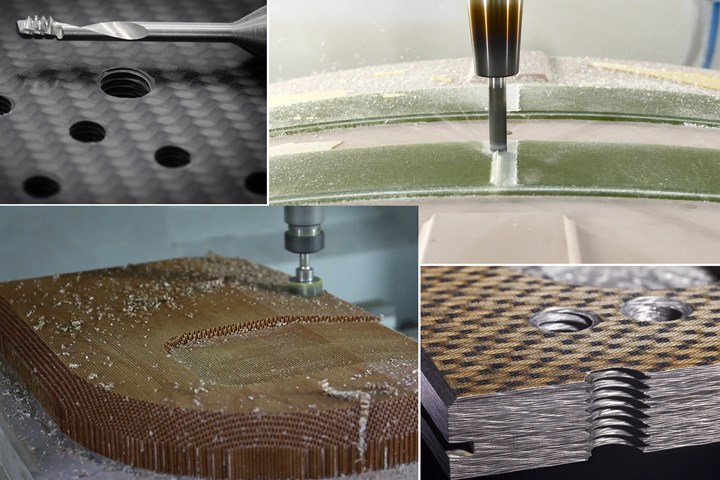

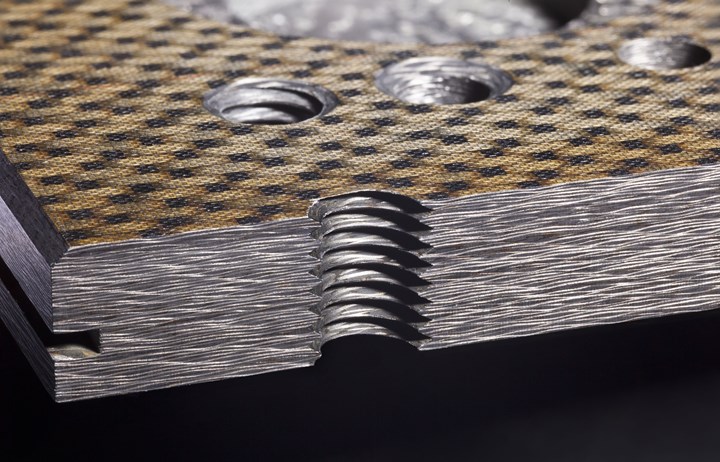

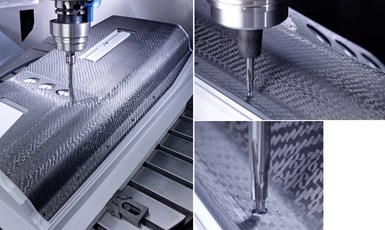

Hufschmied machining tools for composite materials (bottom) are designed to produce high-quality surfaces without reworking.

When it comes to machining, plastics and fiber-reinforced composites are often underestimated by users who come from the metal-cutting industry — after all, they are not particularly hard. However, the temperature sensitivity of thermoplastics creates risk for melting the material, while composites may delaminate and fray. Manual reworking is often seen as unavoidable. But Hufschmied believed it was possible to do better, and thus, has developed tools to eliminate reworking and improve quality across a wide range of composite materials and machining processes. To date, Hufschmied has developed more than 200 standard tool geometries for fiber-reinforced composites, including ceramic matrix composites (CMC).

One example of Hufschmied’s tools designed for composites is the HexaCut. As explained in the video below, this provided a solution for Steptics’ (Munich, Germany) automated production of carbon fiber-reinforced polymer (CFRP) prosthetics. The HexaCut is used to machine the tread (bottom) and outer contour of the foot/spring element for a lower leg prosthetic, which was particularly challenging to machine without burring. As explained by Daniel Kun, Steptics CEO, the HexaCut has a drawing cut — it pulls the fibers and then cuts — which is important for machining the spring element’s orthotropic laminate structure of unidrectional (UD) reinforcements. Steptics also chose a diamond coating, which provides smooth, burr-free surfaces and a longer tool life. HexaCut has also been designed for challenging material combinations, such as with copper mesh, common in the aerospace industry.

Glass fiber and natural fiber composites

Another example of Hufschmied’s composites-focused tools is with the German automotive supplier Reinert Kunststofftechnik (Bissingen an der Teck, Germany) which manufactures the basic frames of many brand-name sports seats from polyamide (PA6) with 47% glass fiber content. During final machining of circular pockets and drill holes in the 2-millimeter-thick blanks, the thermoplastic composite material frayed at the edges, so that each of the 45,000 seat shells/year had to be deburred by hand.

Hufschmied’s development team trialed the T-Rex tool at 8,000 rpm with a 2 meter/second feed rate. The helical path of the tool plunged into the circular pockets and milled in the opposite direction, producing smooth edges without delamination of the composite material. T-Rex has four cutting edges with a patented geometry that offers pulling and pushing action and roughing and finishing functions in one tool. This limits heat generation and vibrations during machining. The tool is also available with a microcrystalline diamond coating to counter the abrasive effect of glass or carbon fibers. Reinert was able to eliminate the entire manual deburring process and also reduced milling time by 40%.

Hufschmied has also performed research on natural fibers, such as flax and hemp, used to reinforce automotive door panels, for example. Natural fibers are gaining increased application due to their sustainability benefits, but they exhibit greater fluctuations in their characteristic values and can char if the heat input is too high. Hufschmied has worked with Bcomp (Fribourg, Switzerland) to optimize machining of composites made with its powerRibs and ampliTex materials. Trials were performed with the T-Rex tool and processes for specific parts were optimized.

Process optimization as a service

In addition to its standard tools, Hufschmied also works with manufacturers to develop specially optimized tools for their material, part and process. For this, it pursues a holistic view of the process chain — from CAD/CAM programming and machine parameterization through to the individual tool. For example, if you are working on a machine with relatively low power and high speed, there must be space for a high chip volume and usually only two or three cutting edges can be provided. If, on the other hand, a rather slow machine with a high torque is to be used for cutting, the tool can be equipped with up to six cutting edges or more. By analyzing the whole process and the materials, Hufschmied is typically able to provide considerable improvements that pay for themselves quickly in serial production.

Industry 4.0: SonicShark

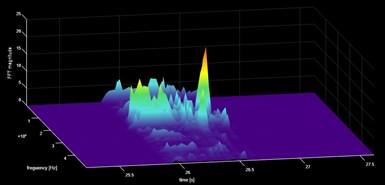

With the opening of its development center in 2018, Hufschmied began accelerating its research into digitization and how it could further improve machining operations for its customers. Here is where the SonicShark inline quality control system was developed. Launched in 2021, this system uses sensors to evaluate vibrations and acoustic signals in the machine tool and equipment. Combined with machine data and an adaptive AI, it monitors the machining process, workpiece and tool quality. It can recognize anomalies in production processes, identify material inhomogeneities and “hears” the onset of tool wear.

SonicShark technology uses sensors to capture and analyze time-based data to maintain quality, predict tool maintenance and maximize tool life. Source | Hufschmied

Depending on the size of the workpiece for which inline quality control is to be implemented, one or more structure-borne sound sensors are attached to the workpiece. A computer next to the CNC machine collects the time-based sensor data as well as the machine data such as position, tool speed and feed. The system creates a database of baseline data and then compares this with actual data during machining. It analyzes the differences and patterns and visualizes this on a screen. If deviations beyond defined threshold values occur, a warning is issued.

Such inline control saves money. It is estimated that quality assurance and testing comprise 25-30% of manufacturing costs in machining. Additional savings are possible through longer tool use before replacement. Normally, companies define safety reserves for tool replacement based on qualification tests. This reserve is often quite conservative to avoid quality problems or production interruptions. Hufschmied estimates that about 40% of the tools qualified in this way could run longer. Tests have shown that SonicShark reliably detects wear and predicts tool lives with a margin of ±3%. This means tools can be used longer without risk of reduced quality parts.

Cutting Edge World and future developments

Hufschmied has also established the Cutting Edge World (CEW) cloud platform for data exchange to optimize tool use. Hufschmied provides users with the final dimensions and DXF (data exchange format, for sharing across applications) data of each individual tool delivered.

A QR code on the tool enables users to access a database of all the tools the company uses and can track tool life and materials processed to optimize tool use. Hufschmied can also use CEW to share tool life and logged process and machine data between its own plants or with the tool manufacturer, material suppliers or machine builders, for example, to examine issues or explore new developments.

Note, however, that the data on the CEW platform is strictly private. External access must be explicitly authorized. For example, Hufschmied sets a check mark in the system to make additional tool data available to a customer. In the same way, customers can release data to others — for example, anonymized cutting data or only tool life and processed material. Project rooms can also be set up on the platform for more intensive collaboration in process optimization. This sharing of data to jointly improve machining processes is already being used by a major automotive customer. There is also a project in which Hufschmied is carrying out trial machining of a sophisticated CFRP component for a customer.

Hufschmied will continue to advance these and other technologies to improve the finished surfaces, tool life, cycle time and cost for machining complex composite materials and components.

About the Author

Thomas Niefenecker

Thomas Niefenecker started at Hufschmied (Bobingen, Germany) in 2011 as a trainee, moving to internal sales and service in 2014. and sales team leader in 2017. He earned an MBA in 2021 and has served as Hufschmied sales director overseas since 2022.

Related Content

Prepreg compression molding supports higher-rate propeller manufacturing

To meet increasing UAV market demands, Mejzlik Propellers has added a higher-rate compression molding line to its custom CFRP propeller capabilities.

Read MoreActive core molding: A new way to make composite parts

Koridion expandable material is combined with induction-heated molds to make high-quality, complex-shaped parts in minutes with 40% less material and 90% less energy, unlocking new possibilities in design and production.

Read MoreOtto Aviation launches Phantom 3500 business jet with all-composite airframe from Leonardo

Promising 60% less fuel burn and 90% less emissions using SAF, the super-laminar flow design with windowless fuselage will be built using RTM in Florida facility with certification slated for 2030.

Read MoreIndustrializing additive manufacturing in the defense/aerospace sector

GA-ASI demonstrates a path forward for the use of additive technologies for composite tooling, flight-qualified parts.

Read MoreRead Next

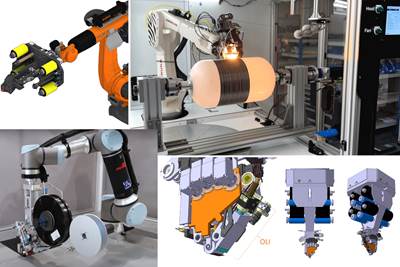

The next evolution in AFP

Automated fiber placement develops into more compact, flexible, modular and digitized systems with multi-material and process capabilities.

Read MoreAerodynamic considerations when repairing complex composite structures

An example process gives steps and issues to consider when determining the most effective repair method for preserving the aerodynamic surface of a complex-contoured composite sandwich structure.

Read MoreFastener selection for composite materials

How to navigate terminology, materials and functionality in choosing the right fastener for components or assemblies involving composite materials.

Read More