INCA Renewtech awarded $10 million to invest in commercial biocomposites facility

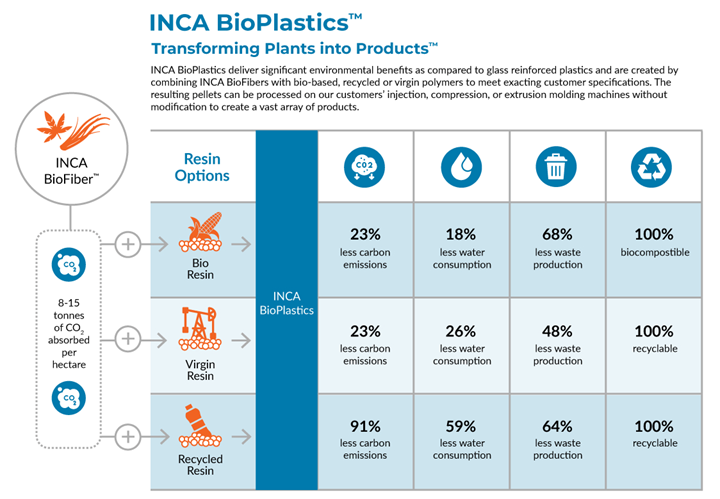

Under Alberta’s Circular Economy Projects, INCA will construct and operate a facility for processing and manufacturing waste hemp into BioPlastics and Biocore composite materials for wide industry use.

Share

Read Next

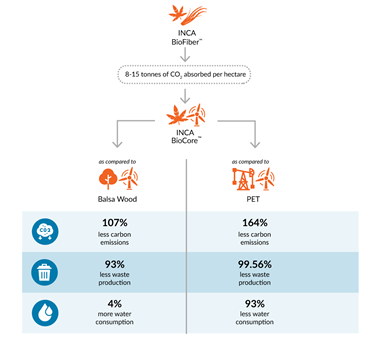

The government of Alberta (Canada) is advancing the province’s global leadership in the circular economy by committing $58 million through Emissions Reduction Alberta (ERA) to projects across the province worth $528 million. Under the ERA’s Circular Economy Challenge, INCA Renewable Technologies (Kelowna, Canada) has been awarded a $10 million grant toward constructing and operating what is reported to be a first-of-its-kind commercial processing and manufacturing facility to process waste hemp stalk from hemp grown for protein and manufacture it into BioPlastics and BioCore — a core material that can be deployed instead of rainforest balsa wood and petroleum-based PET in wind turbine blades and marine cores.

In addition to these developments, INCA says processed fiber will be shipped to Indiana, where it will be manufactured into biocomposite prepreg and BioPanels for the automotive and RV industries (see “INCA Renewtech to build advanced biocomposites manufacturing facility in Alberta, Canada”). INCA currently has commercialization partnerships with Gurit (Wattwil, Switzerland and Bristol, R.I., U.S.), Toyota North America (Plano, Texas, U.S.) and Genesis Products (Elkhart, Ind., U.S.) and its customer Winnebago Industries (Forest City, Iowa, U.S.). Joint development agreements with Canadian- and U..S-based polymer producers are also under finalization.

“This funding will enable INCA Renewtech to significantly accelerate construction of our state-of-the-art hemp processing and composites manufacturing factory,” David Saltman, chairman and CEO, INCA Renewtech, says. “We will purchase waste straw from farmers currently growing hemp for plant-based protein and transform this renewable resource into advanced biocomposites for the automotive, marine, wind energy and consumer plastics industries.”

The Circular Economy Challenge projects support waste reduction, material and feedstock substitution, value recovery and reduction of the lifecycle environmental footprint of materials and products — producing high-quality fertilizer for farmers, recycling asphalt from roof shingles, sequestering carbon in concrete and novel plastics recycling are some examples of the technology solutions receiving funding. Ultimately, these technology solutions can reduce the impacts of material production, processing and disposal. The innovations invested in will support industry competitiveness, new venture creation and economic diversification.

If successful, the projects will reportedly result in cumulative greenhouse gas (GHG) reductions of up to four million tonnes by 2050 — equal to offsetting the GHG footprint of 1 million homes. Circular Economy Challenge funding is expected to create 1,835 person-year jobs in Alberta and have a $350 million GDP impact in the province by 2025.

The investment aligns with provincial initiatives including the proposed Extended Producer Responsibility (EPR) approach, the agricultural plastics recycling initiative and the Natural Gas Vision and Strategy’s goal to establish Alberta as a center of excellence for plastics diversion and recycling

“A more sustainable, diversified provincial economy requires using our resources more wisely, we need to think about waste as a resource rather than a cost,” Justin Riemer, CEO, Emissions Reduction Alberta, adds. “This investment in converting waste into other uses is going to make a real difference.”

Projects were selected through ERA’s competitive review process. A team of experts in science, engineering, business development, commercialization, financing and GHG quantification conducted an independent, rigorous, transparent review overseen by a Fairness Monitor.

All ERA funding recipients are required to produce a final outcomes report that is shared publicly for the broader benefit of Alberta, as well as other funding proposals. Funding recipients will be required to report on project outcomes, achievements and lessons learned including GHG reductions, job creation and other environmental, economic and social benefits.

All funding is sourced from the province’s Technology Innovation and Emissions Reduction (TIER) fund.

Related Content

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreDevelopment of a composite liquid hydrogen tank for commercial aircraft

Netherlands consortium advances cryogenic composites testing, tank designs and manufacturing including AFP, hybrid winding, welding of tank components and integrated SHM and H2 sensors for demonstrators in 2025.

Read MoreRevisiting the OceanGate Titan disaster

A year has passed since the tragic loss of the Titan submersible that claimed the lives of five people. What lessons have been learned from the disaster?

Read MoreMFFD longitudinal seams welded, world's largest CFRTP fuselage successfully completed

Fraunhofer IFAM and partners have completed left and right welds connecting the upper and lower fuselage halves and sent the 8×4-meter full-scale section to ZAL for integration with a cabin crown module and testing.

Read MoreRead Next

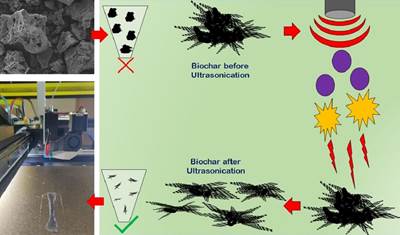

New research developments identify new methods for bio-derived carbon filler reinforcement for biocomposites

Sustainable methodologies employed by researchers from Tuskegee University enable the synthesis of carbon from biomass-based precursor materials, and its effective reinforcement in composites.

Read MoreSeaBioComp project develops biocomposite demonstrator products for marine applications

Prototype products explore thermoplastic polymers, natural fibers and 3D printing technologies to effectively reduce the use of fossil-based materials in the marine sector.

Read MoreComposite trends gaining industrial traction for 2026

Startups & Investors topics over the last year show the industry is rapidly gaining maturity while benefiting from macro-trends in circularity, AI and TPC and high-rate manufacturing, all potential gains for investors.

Read More