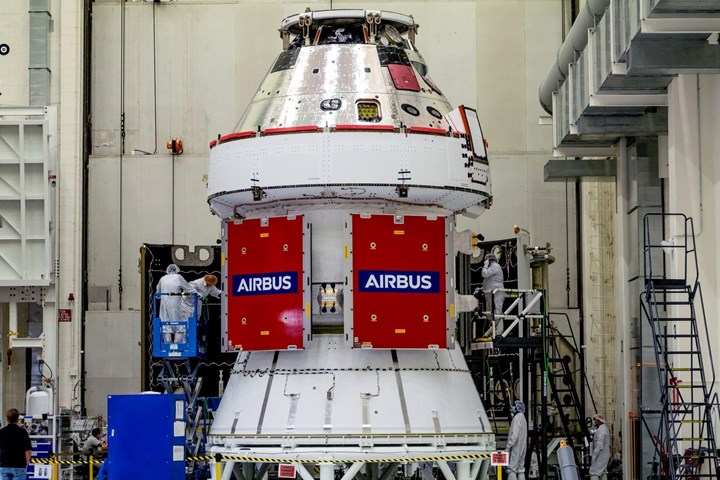

Airbus-built European Service Module is ready for launch with Orion spacecraft

The European Space Module (ESM) will power NASA’s Orion spacecraft to and from its lunar orbit as part of the Artemis missions, featuring a web assembly of carbon fiber sheets and deployable CFRP rigid panels.

NASA’s (Washington, D.C., U.S.) Orion spacecraft is to be launched in a few days from Cape Canaveral, Florida-based Kennedy Space Center on its mission to the moon. The Airbus (Bremen, Germany) built European Service Module (ESM) — comprising composite materials — will power Orion to and from its lunar orbit as part of NASA’s Artemis missions. Airbus has developed the ESM as prime contractor for the European Space Agency (ESA) and is designing and manufacturing an additional five ESMs.

The ESM is a key element of Orion, the next-generation spacecraft that will carry astronauts beyond low Earth orbit (LEO) for the first time since the Apollo program ended in the 1970s. The module provides propulsion, power and thermal regulation and will supply astronauts with water and oxygen on future missions. The ESM is installed below the crew module. Together, the two make up the Orion spacecraft.

“The launch of NASA’s Orion spacecraft with the European Service Module has historic significance 50 years after the last astronaut lunar mission and is another major step toward returning astronauts to the moon,” Jean-Marc Nasr, head of Space Systems at Airbus, says. “The program is now moving forward and we are ready for a return to the lunar surface in 2025, together with our customers ESA and NASA and our industrial partner, Lockheed Martin Space.”

The launch of the first Orion spacecraft using NASA’s new Space Launch System (SLS) rocket will be crewless and will take Orion more than 70,000 kilometers beyond the moon to demonstrate its capabilities. Artemis II, planned for around 2024 and powered by the ESM-2, will carry four astronauts to space and return them safely to Earth. Then, a year later, the ESM-3 will ensure that another Orion capsule safely carries the first woman to the moon. The technologies developed and experience collected during the Artemis missions will be fundamental for possible future long-term missions to Mars, for example, Airbus notes.

The ESM consists of more than 20,000 parts and components, from electrical equipment to thrusters, solar arrays, propellant tanks, life support materials and several kilometers of cables and hoses.

Artemis I stack rolls out to the launch pad.

The ESM is a cylinder about four meters high and wide. It is similar to the European Automated Transfer Vehicle (ATV 2008-2015), also built by Airbus, and features the signature four-bladed solar array (19 meters in diameter when deployed), which reportedly generates enough power for two households. The service module’s 8.6 tons of propellant power the main engine, eight auxiliary engines and 24 smaller thrusters ensure navigation and attitude control.

At launch, the ESM weighs a total of just over 13 tons. In addition to serving as the main propulsion system for the Orion spacecraft, the ESM will enable orbital maneuvering and attitude control. Airbus says it will provide the crew with key life support elements such as water and oxygen and regulate thermal control while docked to the crew module. Also the unpressurized service module can be used to carry additional payloads.

For the first landing on the moon, the Orion spacecraft will dock with the international Lunar Gateway — a lunar-orbiting platform that will enable sustained space exploration and expand humanity’s presence in space.

Learn more about the targeted launch date, “NASA announces targeted launch of Artemis I uncrewed flight test.”

Related Content

Prepreg compression molding supports higher-rate propeller manufacturing

To meet increasing UAV market demands, Mejzlik Propellers has added a higher-rate compression molding line to its custom CFRP propeller capabilities.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreThe next-generation single-aisle: Implications for the composites industry

While the world continues to wait for new single-aisle program announcements from Airbus and Boeing, it’s clear composites will play a role in their fabrication. But in what ways, and what capacity?

Read MoreDevelopment of a composite liquid hydrogen tank for commercial aircraft

Netherlands consortium advances cryogenic composites testing, tank designs and manufacturing including AFP, hybrid winding, welding of tank components and integrated SHM and H2 sensors for demonstrators in 2025.

Read MoreRead Next

Carbon fiber enables new, low-CO2 Skyrora orbital launch vehicle

U.K. private space company is developing and testing orbital launch vehicle Skyrora XL to carry small satellites in Earth’s orbit using eco-friendly fuel, a unified systems design and composites.

Read MoreComposite trends gaining industrial traction for 2026

Startups & Investors topics over the last year show the industry is rapidly gaining maturity while benefiting from macro-trends in circularity, AI and TPC and high-rate manufacturing, all potential gains for investors.

Read MoreCutting engine weight via thermoplastic composite guide vanes

Greene Tweed replaces metal stator vanes with its DLF material co-molded with a metal leading edge that meets performance, cost and high-rate production targets while cutting 4 kg per engine.

Read More