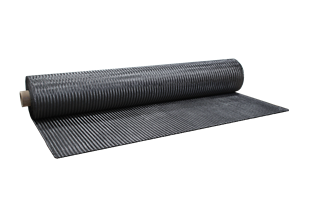

As composites manufacturing is applied increasingly to high-volume parts, material efficiency will become paramount. This presentation will review the use of braiding technologies to produce high-quality, conformable fabrics that offer users significant cost advantages when making composite parts. A&P's braided fabrics are tailored to meet areal weight and width requirements, minimizing waste, and are customized to the architecture required for optimal performance. This presentation will explore the manufacturing benefits of braided fabrics, including handling performance, ease of layup, and infusion efficiency.

Agenda:

- Less scrap – creating optimized widths, areal weights, and architectures

- Easier handling – manufacturing aids including laminations and powder coating

- Reduced manufacturing time – from composite tooling to high-performance materials, including thermoplastics

- Lightweighting through optimized design

Presenters:

Nathan Jessie

Senior Application Engineer, A&P Technology

Nathan Jessie started at A&P in 2007, designing braids for use in aerospace, industrial, recreation and automotive applications. His composite design expertise enables optimization of braid architectures to provide design and manufacture solutions. Nate earned a composite materials engineering degree from Winona State University in 2007.

Billy Wood

Program Manager, Braided Fabrics; A&P Technology

Billy Wood manages A&P's line of braided fabrics, identifying areas of growth and fabric solutions for a variety of markets. Prior to A&P, Billy held positions of increasing responsibility at Solvay. Billy holds a BS in chemistry and biology from the University of South Carolina and an MBA from the University of Delaware.