Yes, you clean tooling board with dry ice

Coastal Enterprises and Cold Jet cooperate to assess the use of dry ice blasting to clean the contaminated surface of a high-density urethane tooling board material.

Dry ice blasting of Coastal Eneterprises tooling board.

Dry ice blasting is often used to clean metallic molds in composites fabrication operations, and it can do so without damaging the mold itself. Coastal Enterprises Co., however, wondered if dry ice blasting could be used to clean its Precision Board high-density urethane (HDU) tooling board material. Coastal worked with dry ice equipment supplier Cold Jet LLC to clean a PBLT70 tool coated with FSC88 WB Primer.

The results? Dry ice cleaning removed the primer and left the Precision Board HDU surface smooth and with no visible surface deterioration.

The test replicated cleaning contaminants off of a fouled mold without damaging the material, allowing for multiple cycles of cleaning and resealing of a Precision Board tool.

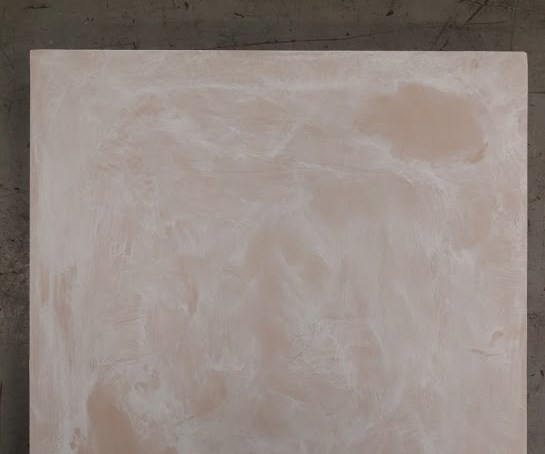

Tooling board before cleaning.

Dry ice blasting is similar in concept to sand or water blasting, but dry ice blasting uses non-abrasive media in the form of recycled CO2 pellets that will not damage surfaces. The combination of dry ice blasting’s kinetic energy and thermal effects break the connection between the contaminant and surface, lifting it away. Unlike blasting with other media, dry ice does not leave any secondary waste, because the dry ice particles sublimate upon impact – converting from solid to gas.

Tooling board after cleaning.

Dry ice cleaning can help meet strict industry demands by providing a composite tool cleaning solution that is fast, delicate and does not use chemicals or solvents. It is a nonabrasive cleaning solution that extends the life of molds and equipment by eliminating the need for harsh chemicals, wire brushes and coarse pads.

Tooling used for, but not limited to, compression molding, resin transfer molding, extrusion, prepregging and wetlayup are all said to be good applications for dry ice blast cleaning.

Testing was done on a sample of Precision Board PBLT70 partially coated with FSC88 WB Surface Primer. Cold Jet used the i3 MicroClean, with conventional block dry ice, MC88 nozzle, and 60 psi blast pressure.

According to Steve Wilson, director of global business development for Cold Jet, “The contaminant on this sample required a little less pressure than the uncoated sample of PBLT75 that we also tested, but could be dialed in to clean quite nicely.” While it cleaned a bit slower than the second sample, the process can be adapted for larger nozzles with the SDI Select60 machine from Cold Jet.

“The blast pressure is on the very low end of the process capabilities,” says Wilson. “There is plenty more cleaning capacity if needed. From visual, 400X photos and calibers, I can see no deterioration to the Precision Board sample surface. About two-thirds of it has been cleaned so that you can see the comparison between before and after. The surface of the part still feels very smooth.”

Testing on the second sample of Precision Board, PBLT75, with no coating, was also done with Cold Jet’s i3 MicroClean machine.

For more with Coastal Enterprises, check out Episode 14 of CW Talks: The Composites Podcast.

Related Content

KAI demonstrates thermoplastic and infused structures for future airframes

Korea Aerospace Industries advances its expertise through a welded TPC fuselage section and resin-infused wing skin module and torsion box demonstrators.

Read MoreBladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

Read MoreSyensqo, Teijin Carbon achieve aerospace qualification for composite resin

Resin infusion system Prism EP2400 achieves NCAMP qualification with Teijin Carbon’s advanced NCF and UD reinforcements.

Read MorePrepreg compression molding supports higher-rate propeller manufacturing

To meet increasing UAV market demands, Mejzlik Propellers has added a higher-rate compression molding line to its custom CFRP propeller capabilities.

Read MoreRead Next

Robotic computed laminography brings X-ray CT resolution to large composite structures

Omni NDE collaborative robots, X-ray end effectors and Voxray’s reconstruction approach enables 5-micron inspection of aerospace parts without size constraints.

Read MoreFrom PMCs to sandwich composites: Tracing the path of test method standardization

Over the decades, progression of PMC and sandwich composite test method development and standardization has been shaped by the requirements of the composites industry.

Read MoreComposite trends gaining industrial traction for 2026

Startups & Investors topics over the last year show the industry is rapidly gaining maturity while benefiting from macro-trends in circularity, AI and TPC and high-rate manufacturing, all potential gains for investors.

Read More