Virgin Galactic moving closer to commercial service

Virgin’s all-composite VMS Eve was recently relocated to Spaceport America where the company has begun operations, implementing a newly designed Mission Control and preparing for commercial service.

VMS Eve Source | Virgin Galactic

As we celebrate the final day of National Composites week, the theme of the day is “how composites help us explore.” The past year has been filled with exciting developments in the space industry and collaborations between commercial space companies and government agencies. Recent developments at Virgin Galactic (Mojave, Calif., U.S.) are an example of some of the exciting work that is being done.

Recently the company’s mothership the all-composite VMS Eve was relocated to Spaceport America (Sierra County, New Mexico). Virgin Galactic made the decision to move spaceline operations to Spaceport America after two successful spaceflights. The company has begun operations out of the spaceport, implementing a newly designed Mission Control and flight briefing rooms. The move is another step toward readying Virgin Galactic for commercial service.

From Spaceport America, VMS Eve will fly simulated spaceship launch missions, testing in flight communications and airspace coordination. The spaceplane will return to Mojave later this year to pick up Virgin’s carbon fiber composites-intensive spaceship Unity and return to Spaceport America where Virgin will continue Unity’s flight test program.

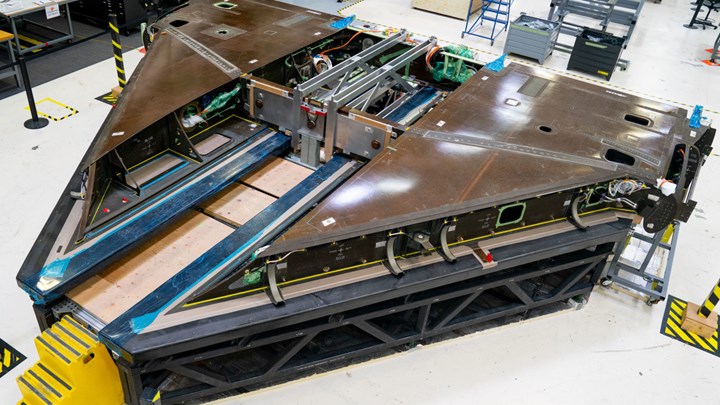

Virgin Galactic completes wing for next spaceship. Source | Virgin Galactic

In addition, last month, the Spaceship Company (TSC, Mojave, Calif., U.S.), Virgin Galactic’s space-system manufacturing organization, completed the systems install and main structure for the wing of the next spaceship in Virgin Galactic’s fleet. The completion of this significant assembly means that the team can begin preparing for the mate of the spaceship’s fuselage to the new wing and moves it closer to beginning its flight test program.

Related Content

-

One-piece, one-shot, 17-meter wing spar for high-rate aircraft manufacture

GKN Aerospace has spent the last five years developing materials strategies and resin transfer molding (RTM) for an aircraft trailing edge wing spar for the Airbus Wing of Tomorrow program.

-

Materials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.

-

Cycling forward with bike frame materials and processes

Fine-tuning of conventional materials and processes characterizes today’s CFRP bicycle frame manufacturing, whether in the large factories of Asia or at reshored facilities in North America and Europe. Thermoplastic resins and automated processes are on the horizon, though likely years away from high-volume production levels.

.png;width=70;height=70;mode=crop)