Scott Francis Contributing Editor

Scott Francis is an editor for CompositesWorld and Products Finishing media brands, as well as a contributor to related properties of Gardner Business Media. He has also edited for the Writer's Digest, HOW, Popular Woodworking media brands and has authored books on a range of topics including the Monster Spotter's Guide to North America (HOW Books 2007).

Scott has a bachelor’s degree in writing and editing and a minor in biology from Western Carolina University. PRESS KIT

Roboze 3D printing partners with Yamaha Motor Racing

Yamaha Motor Racing selects Roboze as its technology partner for high-performance 3D printing with super polymers and composite materials.

Read MoreNadcap forms additive manufacturing task group

New task group will focus on all additive manufacturing activity within Performance Review Institute’s Nacap program.

Read MoreJetZero unveils plan for BWB midmarket airliner, tanker

Blended wing body aircraft design targets need for new midmarket airplane (NMA) and defense tanker-transport program.

Read MoreELIOT Project finds solvolysis best method for aerospace biocomposites recycling

Aimplas and TNO study analyzed 12 methods for six different biocomposites. Solvolysis and pyrolysis proved the two most promising alternatives tested in large-scale production at a pilot plant.

Read MoreNCC reaches milestone in composite cryogenic hydrogen program

The National Composites Centre is testing composite cryogenic storage tank demonstrators with increasing complexity, to support U.K. transition to the hydrogen economy.

Read MoreTempest Program receives new funding

Ministry of Defence awards £656 million to BAE Systems for Tempest next-generation combat aircraft program.

Read MoreIndustrial Fiberglass Specialties: From corrosion-resistant industrial pipes to specialty custom projects

Based in Dayton, Ohio, U.S., IFS recently developed an FRP console for the U.S. Air Force using a custom mold design and specialized paint.

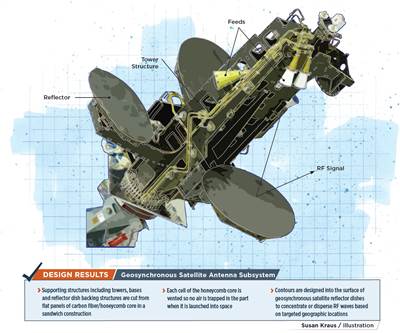

Read MoreTooling, precision enable composites in satellite subsystems

Tight tolerances drive design and engineering of large-format composite component and dishes to create unique satellite structures.

Read MoreThe evolution of composites in NASCAR

The growing role of carbon fiber in stock car racing.

Read MoreComposites in the race to space

Advanced materials use in current and upcoming NASA missions.

Read MoreUK composites structure manufacturer continues to expand

Norco, which built its reputation as a manufacturer of large glass fiber reinforced structures, continues to grow and currently offers a wide range of bespoke composite products.

Read MoreNational Composites Centre unveils digital composites technologies

The U.K.’s National Composites Centre unveils new composites manufacturing technologies, marking the culmination of a two-year, £36.7m digitization project.

Watch.png;maxWidth=250;quality=70)