Highlights: Future of Thermoplastics Composites Conference, TPRC

The ThermoPlastic composites Research Center celebrates its 10th anniversary by looking forward to the growth in thermoplastic composite applications.

If you are interested in thermoplastic composites, then the place to be was the ThermoPlastic composites Research Center (TPRC, Enschede, Netherlands) on Oct 8, when it hosted a one-day conference at the University of Twente to celebrate its 10th anniversary. However, rather than looking backwards over the last 10 years, this event was very much looking forward to the growth in thermoplastic composite applications.

The TPRC was founded in 2009 with four initial partners: The Boeing Company, GKN Fokker, Toray Advanced Composites (formerly TenCate Advanced Composites) and the University of Twente. This has changed dramatically over the last decade, with 22 partners mainly in the aviation and automotive industries representing the entire value chain including OEMs, Tier 1 suppliers, part fabricators, material suppliers and equipment manufacturers. The TPRC focuses on pre-competitive research and employs 40 people including graduate and PhD students at its own 8,100-square foot facility close to the University of Twente. More than eight PhD thesis publications have resulted, ranging in topic from consolidation of laser-assisted automated fiber placement (AFP) laminates and fusion-bonded thermoplastic composites to recycling.

ThermoPlastic composites Research Center partners. SOURCE | TPRC

Kickoff and Boeing keynote

The 10th anniversary conference comprised a full day of presentations, panel sessions and networking opportunities, as well as displays from the TPRC and many of its partners. Harald Heerink, director of the TPRC, welcomed more than 300 attendees who had come from Europe, North America, and Asia, with more than 55% of the participants from organizations that are not TPRC members. The opening presentation was by Professor Remko Akkerman, one of the initiators of the TPRC and the scientific director from its inception. He set the stage for the day in his presentation: The Basics of Thermoplastic Composites - Getting it Right First Time.

Dr. Alex Rubin, senior technical fellow, The Boeing Company, gave the keynote presentation: Thermoplastic Composites Take Flight. He provided several visual representations of the aerospace and defense industry and where it is headed. In addition, he gave a snapshot of what the future may hold and the types of vehicles that may utilize thermoplastic composites. Rubin predicted that the urban air mobility (UAM) market will grow significantly, which will require the development of personal air vehicles produced in high volumes, and thus, requiring reinforced thermoplastics.

Experts and panel sessions

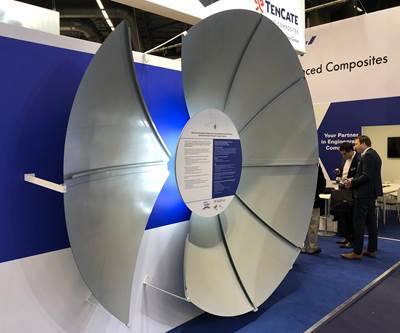

The focus then moved to thermoplastic composite materials with Frank Meurs and Winand Kok of Toray Advanced Composites. They gave a brief description and introduction of Toray’s (and TenCate’s) history and growth. They also discussed the evolution of the company and range of materials solutions they now provide.

GKN Fokker has championed thermoplastic applications on large commercial aircraft and business jets for decades, and its head of R&D, Arnt Offringa, gave a proactive presentation themed Achieving Technology Maturity Together. Offringa began his talk by reminding the audience of the contradictory social trends of reducing carbon emissions, which drives many to find alternatives to air travel, while at the same time, in many parts of the world, the growing middle class wants more opportunities to travel by air. He highlighted that thermoplastic composites can offer weight reduction opportunities and, therefore, a reduced carbon footprint, particularly in fuselage applications. Offringa also discussed defect-free manufacturing, the potential for recycling and that thermoplastic composites are still at the beginning of their maturity curve.

Throughout the day, technology expert Danny Mekić acted as moderator. Using Buzzmaster interaction technology, the audience was able to submit questions and respond to the presentations and prompts from Danny, which were projected onto the screen. This was very effective in broadening the discussion compared to the usual Q&A approach, and made the whole event very engaging and visually interactive.

A panel session on the theme Starting and Growing in the Thermoplastic Composites Market brought together representatives from a variety of companies including parts fabricators ATC Manufacturing, Dutch Thermoplastic Components and Herone, process modelling software supplier Aniform, AFP equipment supplier Coriolis Composites and REIN4CED, which produces composite material forms and bicycles. Each company gave a short introduction about their business, followed by a broader discussion prompted by questions from both Danny and the audience. The companies were paired by “Starting,” “Running,” and “Growing” a business in the thermoplastic composites market space. Discussion and audience engagement were energetic, and the presentations were well received.

The theme then moved to Tier 1 suppliers with presentations and joint discussion by Mike Grondalski, VP operations for Collins Aerospace, and Brad Blonigen, senior manager R&T for Spirit AeroSystems. Both companies highlighted potential benefits of thermoplastic composites, including performance and lower total cost of ownership. Grondalski and Blonigen highlighted many opportunities to stimulate growth, including common databases, design methodologies, fragmented expertise and the relatively low technology and manufacturing readiness level (TRL/MRL) of thermoplastic composites. This led to a lively discussion on how to accelerate technology adoption including working with competitors.

Training, knowledge-sharing

Final sessions included Thermoplastic Composites and the Battle for Talent and Training the Composite Engineers of Tomorrow. The first was a discussion between two leaders from University of Twente and Saxion University of Applied Sciences, including how the Netherlands has become a center of excellence for reinforced thermoplastics. During the second session, the technical director for the TPRC’s affiliate ThermoPlastic composites Application Center (TPAC), Ferrie van Hattum, and the technical director for the TPRC, Sebastiaan Wijskamp, debated the possibilities and concerns of training and how to retain talent, as well as how universities can be more collaborative while still maintaining uniqueness.

One of the common themes of the day was that in a growing area of technology there is a tension between “golden eggs,” where companies protect the proprietary technology they have developed to maintain a competitive edge and “growing the pie”, where companies share their knowledge and developments for the benefit of the whole industry and expand applications.

Chas Prebil of The Boeing Company and current chairman of the TPRC Consortium Board, gave the concluding comments, emphasizing that the high-performance thermoplastic composites industry is no longer nascent, having grown and broadened to become a global industry.

From the energy level and engagement of the participants, the many spirited discussions during the networking sessions and the overall experience of this conference, the future of thermoplastic composites is indeed bright. Those wanting more on thermoplastic composites should note opportunities in 2020 including:

- ACMA Thermoplastic Composites Conference, San Diego, April – May 1.

- SAMPE Conference, Thermoplastic Composites Tutorial and Conference Sessions Seattle, May 47, 2020.

- ITHEC, International Conference and Exhibition on Thermoplastic Composites, Bremen, Germany, October 1314, 2020.

ATC Manufacturing is a member of the ThermoPlastic composites Research Center.

Related Content

Co-molding SMC with braided glass fiber demonstrates truck bed potential

Prepreg co-molding compound by IDI Composites International and A&P Technology enables new geometries and levels of strength and resiliency for automotive, mobility.

Read MoreBraided thermoplastic composite H2 tanks with co-consolidated molded boss areas to fit EV battery space

BRYSON project demonstrates possible designs, automated manufacturing and low permeability concepts, including EVOH liner and novel PPA matrix.

Read MoreEaton developing carbon-reinforced PEKK to replace aluminum in aircraft air ducts

3D printable material will meet ESD, flammability and other requirements to allow for flexible manufacturing of ducts, without tooling needed today.

Read MoreDevelopment of a composite liquid hydrogen tank for commercial aircraft

Netherlands consortium advances cryogenic composites testing, tank designs and manufacturing including AFP, hybrid winding, welding of tank components and integrated SHM and H2 sensors for demonstrators in 2025.

Read MoreRead Next

Accelerating thermoplastic composites in aerospace

ATC Manufacturing produces millions of thermoplastic composite parts per year, and is investing for future growth.

Read MoreWelding thermoplastic composites

Multiple methods advance toward faster robotic welds using new technology for increased volumes and larger aerostructures.

Read MoreThermoplastic composites: Poised to step forward

The evolving role of thermoplastic materials and processes and their future in next-generation commercial aircraft.

Read More