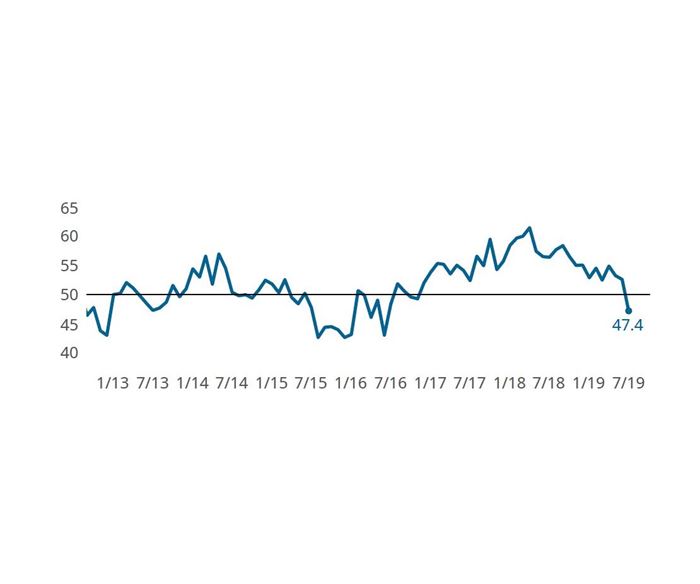

Composites Index contracts on a surprise 5-point decline

Steep contraction in both production and new orders pulled the Composites Fabricating Index to 47.4 for July 2019.

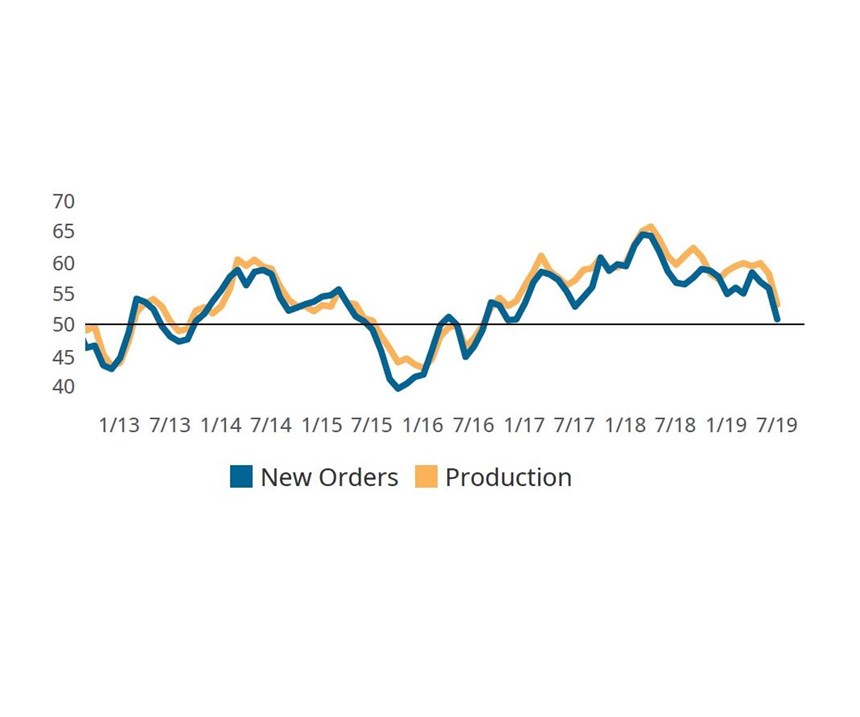

The Composites Index closed July at 47.4, ending a 31-month expansion that first started in late 2016. The duration of the expansion was the longest on record, dwarfing the last recorded expansion on record of 10 months set in 2014. The latest Index reading is 17.4% lower compared to the same month one year ago, and 10.6% lower from just the previous month. Index readings above 50 indicate expanding activity, while values below 50 indicate contracting activity. The further away a reading is from 50, the greater the change in activity. Gardner Intelligence’s review of the underlying data revealed that the Index experienced a steep contraction in both production and new orders. The Index — calculated as an average of its components — was pulled lower further by the ongoing weakness in exports. Contracting new orders and production data pressured backlog activity, which reported the lowest reading in July among all components.

Surprise declines in new orders and production activity have occurred in the past, and each time the Index was able to quickly recover. Since late 2011, there have only been two periods of sustained contraction, both of which lasted for approximately six months before the Index resumed expanding.

More information about the Composites Fabricating Index can be found at http://www.gardnerintelligence.com/.

Related Content

-

Novel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.

-

JEC World 2022, Part 3: Emphasizing emerging markets, thermoplastics and carbon fiber

CW editor-in-chief Jeff Sloan identifies companies exhibiting at JEC World 2022 that are advancing both materials and technologies for the growing AAM, hydrogen, automotive and sustainability markets.

-

Recycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)