The lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

Cyclops-class submersible, Titan, undergoing dive operations, as reported by OceanGate in October 2019. Photo Credit: OceanGate

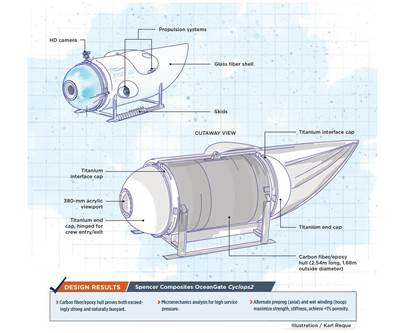

When I first heard, on June 18, the news that OceanGate had lost contact with its Titan submersible during a dive to the Titanic wreck, I was immediately taken back to early 2017 and my interview with OceanGate CEO Stockton Rush. I had spoken to Rush for about an hour about the unprecedented application of carbon fiber composites in the fabrication of the hull of Cyclops 2, Titan’s predecessor. The reason for the interview was to gather information for a story I subsequently wrote for CW, published in May 2017.

The story was part of our Focus on Design series, which, as the name implies, focuses on design and materials use decisions in the engineering of a composite part or structure. My interview with Rush revolved around four main topics: The unusual pressure and cyclic loading of the deep-sea environment, Rush’s stated need for weight reduction in deep-sea submersibles, the design parameters and performance requirements of a carbon fiber composite hull and the safety considerations to be taken into account when operating a deep-sea submersible.

My impression during the interview was that Rush was passionate about deep-sea exploration and had invested much of his personal fortune and energy in development of what he hoped would be a lightweight, durable submersible capable of multiple missions — mostly for scientific purposes. I also got the impression that Rush, although obviously familiar with the basics of composite materials and composites manufacturing, lacked the kind of in-depth knowledge that one might need to develop a high-performance carbon fiber hull of the type he had in mind. Still, Rush had engaged several reputable composite material and technology suppliers to develop the hull, and all of them had significant knowledge and experience. I hoped/assumed Rush would apply whatever expertise they might have shared with him.

A few days after OceanGate reported loss of contact with Titan, the U.S. Navy reported that on the day of contact loss and near the area of contact loss, its sensors had detected “an acoustic anomaly consistent with an implosion.” The subsequent discovery on the ocean floor of Titan’s remains confirmed our fears that Rush and his four passengers had been lost.

The U.S. Coast Guard and other specialists will assess the wreckage and other data and, I hope, eventually report the cause of Titan’s demise. In the meantime, we are left to assess the information available to us, which is voluminous. This has given birth to robust, passionate and widespread speculation (some of it informed, some of it not) about the cause of Titan’s implosion, along with even more speculation about who was to blame. This occurred in mass media outlets like The New York Times, The Washington Post and The New Yorker, plus a litany of social media channels. CompositesWorld got into the act on LinkedIn.

Fruit of the poisonous tree

A byproduct of this speculation is a “fruit of the poisonous tree” phenomenon that sometimes occurs — that is, a tendency to heap blame on everything and everyone associated with the accident. In this case, everyone and everything associated with OceanGate and Titan. Interviews (including mine with Rush), videos and documents of and about Rush and the development of Titan were unearthed and pointed to as proof of Rush’s arrogance, hubris and carelessness. Rush was criticized for not subjecting Titan to classification, which might have detected the flaws apparently built into the submersible. Rush was vilified as a wealthy, entitled, risk-taker who callously sacrificed his life and the lives of his passengers in pursuit of more wealth and notoriety.

On the materials front, other fruit from this poisonous tree included carbon fiber composites, titanium, acrylic polymer (used in Titan’s viewport) and even the Logitech game controller used to operate Titan. Carbon fiber composites received particular vitriol. There was discussion about carbon fiber’s performance in tension (good) and compression (not as good). There was discussion about the insufficiency of the safety factor (2.25) for which the hull was designed. There was discussion about the hull’s fabrication and whether OceanGate had tested appropriately for porosity. There was discussion about cyclic loading on the hull during dives and the lack of testing between dives. Even James Cameron chimed in, declaring that carbon fiber had no business being applied in the manufacture of a hull for a deep-sea submersible.

Again, some of this criticism about how carbon fiber was applied in the Titan hull was made by people with extensive composites experience, and they referenced reliable sources and data to support their arguments. Others, lacking such knowledge, made simply wrong-headed statements about carbon fiber composites — their design, fabrication, capabilities and failure mode. Eventually, particularly in the popular press, carbon fiber itself bore the blame: Titan’s implosion was the result of a hull failure, caused by Rush’s inappropriate application of carbon fiber composites.

The New Yorker finished its report on the Titan accident with this: “But, in 2021, Stockton Rush told an interviewer that he would “like to be remembered as an innovator. I think it was General MacArthur who said, ‘You’re remembered for the rules you break.’ And I’ve broken some rules to make this.” He was sitting in the Titan’s hull, docked in the Port of St. John’s, the nearest port to the site where he eventually died. “The carbon fiber and titanium? There’s a rule you don’t do that. Well, I did.”

The four-legged stool

Of course, anyone who knows composite materials knows it’s not that simple, and it’s not fair to place blame for Titan’s failure at the feet of carbon fiber composites. In fact, this accident, the tragic loss of life notwithstanding, can and should provide an excellent lesson on the important and complex interdependence of materials, design, tooling and fabrication.

There’s an old saying in the composites industry that says you can make a bad part from a good tool, but you can’t make a good part from a bad tool. You can extend this to materials, design and fabrication as well. Fabrication of a composite part that meets the performance requirements of the application depends on intelligent materials selection, robust design engineering, strong tooling development and a well-controlled fabrication regime that includes reliable testing. And, of course, the “requirements of the application” matter — the requirements for the fabrication of a composite aircraft fuselage are significantly greater than the requirements of a composite golf club shaft. Regardless of the application, however, failure in any of these core functions imperils the entire structure and can lead to service failure and, in the worst case, loss of life.

This isn’t a trivial enterprise. Composites, as the name implies, encompass a vast universe of fiber types, fiber formats, resin types, tooling types and fabrication methods, all of which can be mixed and matched to produce structural parts for a variety of uses — aircraft wings, wind turbine blades, sailboat hulls, electric vehicle battery enclosures.

Linking up these variables in a sensible way requires a level of knowledge and experience that many of you have spent entire careers developing. Lacking this knowledge and experience is not a crime, but if you want to apply composites in a new and interesting way, it’s incumbent on you to find the experts who can save you from your ignorance.

What was at risk

Does this mean that carbon fiber composites should not have been applied to the hull of the Titan? It does not. I am confident that the proper combination of materials, design engineering, tooling and fabrication could produce a carbon fiber composite submersible hull capable of doing everything Stockton Rush wanted Titan to do — provide repeated and safe deployment in deep-sea exploration.

Accomplishing this would have required that Rush recognize the profound risk represented by his ignorance and submit to the expertise and knowledge that this industry has to offer. That, apparently, was not Rush’s modus operandi.

We are, undeniably, attracted to innovators and risk-takers like Rush who “push the envelope” and dare to break rules in an effort advance human capability and performance. This was the ethos driving creation of the internet, early space exploration and the advent of the airplane, among other human endeavors. But risk-taking depends entirely on the nature of the risk. Titan was at a depth of 3,500 meters and under 4,993 psi of pressure when it imploded. Such an environment is violent and unforgiving and offers no margin for risk-induced error.

If it were Rush and Rush only in the Titan on June 18, we might have said that he pushed the boundaries and paid the price for his aggressiveness. We might have been thankful that no one else was aboard Titan. And we might have, more quickly, moved into discussion how Rush’s work could lead to better composite hull designs and safer submersibles.

As it stands, we are angry at Rush for having taken four lives with his and eager — appropriately so — to condemn his arrogance. But the opportunity still exists to learn lessons about how composite structures should and should not be developed.

What, exactly, those lessons are, will be explored by CW in the coming weeks. We will assess the technical feasibility of composites use in a submersible and shed much-needed light on how the proper marriage of design, materials, tooling and fabrication can produce a composite hull that meets the performance requirements of a deep-sea environment.

Related Content

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreOne-piece, one-shot, 17-meter wing spar for high-rate aircraft manufacture

GKN Aerospace has spent the last five years developing materials strategies and resin transfer molding (RTM) for an aircraft trailing edge wing spar for the Airbus Wing of Tomorrow program.

Read MoreCycling forward with bike frame materials and processes

Fine-tuning of conventional materials and processes characterizes today’s CFRP bicycle frame manufacturing, whether in the large factories of Asia or at reshored facilities in North America and Europe. Thermoplastic resins and automated processes are on the horizon, though likely years away from high-volume production levels.

Read MoreThe making of carbon fiber

A look at the process by which precursor becomes carbon fiber through a careful (and mostly proprietary) manipulation of temperature and tension.

Read MoreRead Next

Composite submersibles: Under pressure in deep, deep waters

Manned deepsea exploration calls for a highly engineered composites solution that saves weight and preserves life — at 6,500-psi service pressure.

Read MoreThermoplastic composite pipe on the rise in the deep sea

Demonstrators, pilot programs and qualification efforts are paying off as thermoplastic composite pipe (TCP) makers take orders for deep-sea oil and gas applications.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read More

.jpg;maxWidth=300;quality=90)