How to patch a racecar

The current state of the art in automotive CFRP repair borrows heavily from experiences gained in the aerospace/aviation and racing fields.

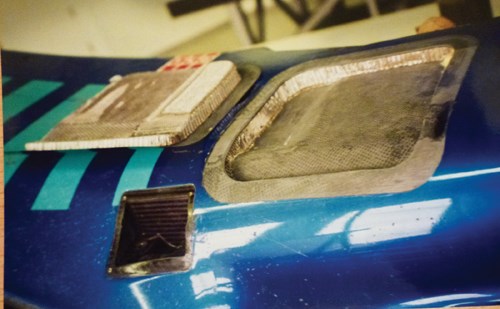

The current state of the art in automotive CFRP repair borrows heavily from experiences gained in the aerospace/aviation and racing fields. This repair was made to a car owned by the Swiss Formula 1 race team, Sauber (circa. July 1997).

Step 1

Damage (white scars/scuffs) sustained by Formula 1 car when wheel was pushed into the CFRP chassis during brush with a wall during a race.

Step 2

Outer skin and core removed from damaged area. Outer skin is chamfered with a 30-mm/1.2-inch wide beveled edge prior to being joined to patch.

Step 3

Repair patch is a precured outer skin with honeycomb that will be bonded in with a paste adhesive.

Step 4

Repair patch is a precured outer skin with honeycomb that will be bonded in with a paste adhesive.

Related Content

-

Guidance for the thermoforming process

A briefing on some of the common foam core material types, forming methods and tooling requirements.

-

Seven tips for machining composite aerospace components

Machining composite materials is a dusty, arduous and abrasive process that is hard on cutting tools, requiring the right combination of strategies and know-how to properly navigate their dynamics.

-

Ceramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

.jpg;width=70;height=70;mode=crop)