Composite Materials: Where to Find Them at NPE2018

If you have come to NPE2018 with composites on your to-do list, you do have options. Over the last few years, several plastics material suppliers have extended their product portfolios in an effort to build a presence in the composites space.

Plastics manufacturing and composites manufacturing theoretically should, given their shared polymer-based DNA, have much in common. However, the predominance of continuous fiber reinforcements in composite parts and structures makes crossover between plastics and composites more the exception than the rule.

Still, if you have come to NPE2018 with composites on your to-do list, you do have options. Indeed, over the last few years, several plastics material suppliers have extended their product portfolios in an effort to build a presence in the composites space.

A few materials suppliers have been active in the composites industry over the last few years. PolyOne (Room S210), for its part, entered the composites industry in a substantial way in 2016 when it acquired Colorado-based sister companies Gordon Composites and Polystrand, both of which specialize in continuous fiber thermoplastics. Polystrand offers a tape-based product called X-ply with 0° and 90° fiber orientations. Fiber is E-glass, S-glass or aramid and resins options are PP, PE and PET. These tapes can be co-molded in direct long fiber processes, including compression molding and injection overmolding. Polystrand also offers a line of sandwich panels that offer good chemical and corrosion resistance, as well as UV stability.

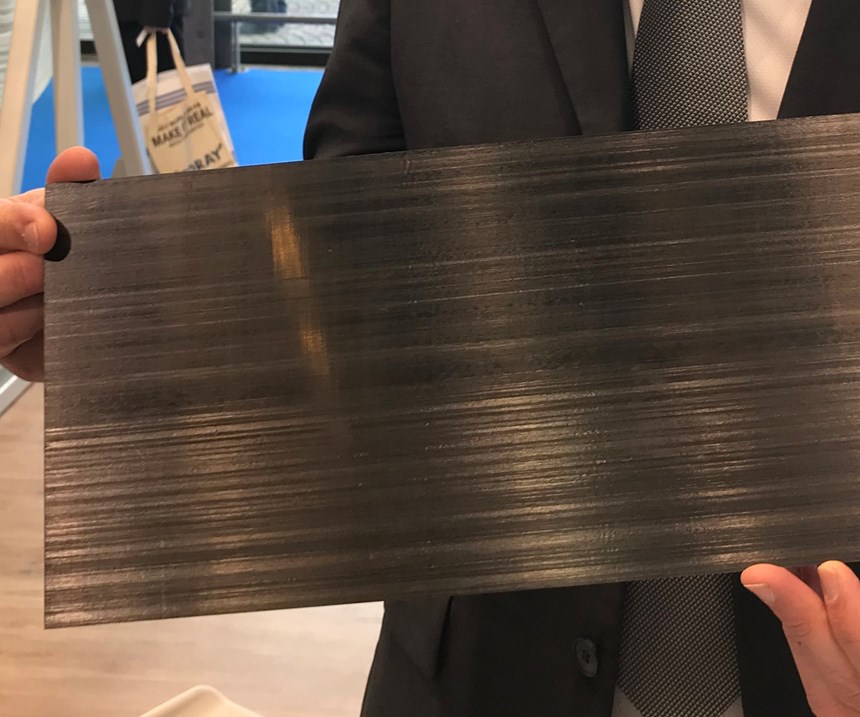

More recently, SABIC (Booth S19001) announced that it has partnered with Airborne International and Siemens to develop a preconsolidated carbon fiber/polycarbonate laminate product called UDMAX. It’s made in a fully automated process developed by Airborne that orients pre-cut unidirectional carbon fiber tapes in 0° or 90° orientations using plies dropped into conveyorized trays, which pass under drop zones as frequently as desired to build the ply stack. The manufacturing system will be located at Airborne, Siemens is providing digital control solutions, and the system is expected to go live in early 2019. SABIC will sell the laminates produced by the line.

A. Schulman (Booth S24023) just introduced to the composites market its Quantum LYTEX SF Series, a styrene-free sheet molding compound (SMC). The product is offered in three varieties, including the 6000 Series (high stiffness/strength), the 6500 series (good surface appearance) and the 6700 Series (good thermal performance). All varieties are also available with A. Schulman’s Forged Preg continuous carbon fiber product. Target applications for this SMC are automotive, sports/consumer, aerospace and oil and gas.

BASF (Booth S15023) offers several resins designed specifically for composites fabrication. Acrodur acrylic resins are targeted toward automotive applications and are particularly compatible with natural fiber reinforcements. Elastocoat is a waterproof polyurethane resin developed for pultrusion and targeted toward the building and construction market. For aerospace applications, BASF offers a line of Ultrason products targeted toward specific parts and structures. These include UD tapes, thermoplastic sheets and panels, impact modifiers for thermosets and honeycomb-cored sandwich panels.

Huntsman Polyurethanes (Booth S20131) features, for composites processing, RIMLINE SK 97018 Polyol. This low-viscosity polyol blend includes internal mold release intended for use in pultrusion processing. Designed as part of a two-component system in conjunction with SUPRASEC 9701 MDI-based isocyanate, the resin is said to offer good wetting characteristics, accelerated line speeds, low pull forces and no VOC emissions. Huntsman says the complete polyol/isocyanate resin system is best suited for structural profiles in applications where strength and durability are required.

Finally, if you have come to NPE in search of carbon fiber reinforcements, there is only one exhibitor featuring this material. Zoltek (Booth S10094) is a long-established carbon fiber manufacturer that specializes in large-tow carbon fiber for wind energy, pressure vessel and automotive applications. At NPE, Zoltek is emphasizing its PX35 chopped carbon fiber products for compounding with thermoplastic resins. The company offers several grades of PX35, each targeted toward or compatible with a certain thermoplastic type, including ABS, PET, PA, PC, TPU, PPS, LCP, PEI, PEEK and more.

Related Content

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreComposite rebar for future infrastructure

GFRP eliminates risk of corrosion and increases durability fourfold for reinforced concrete that meets future demands as traffic, urbanization and extreme weather increase.

Read MoreThermoplastic composites welding advances for more sustainable airframes

Multiple demonstrators help various welding technologies approach TRL 6 in the quest for lighter weight, lower cost.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreRead Next

Composites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read More

.jpg;maxWidth=300;quality=90)