Composites Molds/Tools

Composite parts are typically formed in molds, also known as tools (see CompositesWorld’s introduction to fabrication methods for a primer on manufacturing methods). Tools can be made from virtually any material. For parts that will be produced in low quantities and can be cured at ambient or low temperature, or for prototype parts, where tight control of dimensional accuracy isn’t of prime importance, materials such as fiberglass, high-density foams, machinable epoxy boards or even clay or wood/plaster molds often are suitable.

Latest Molds/Tools Articles

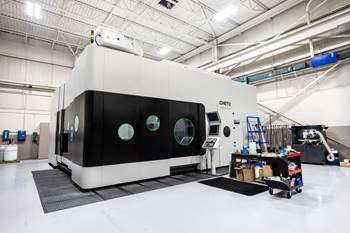

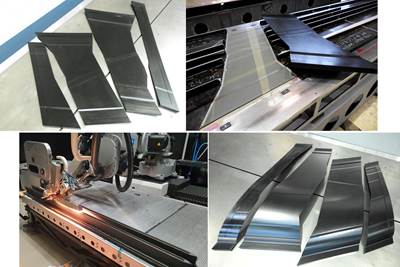

VIEW ALLCentury Tool investment boosts efficiency, capability in tooling for composites

Designer and builder of compression molds for composite structures installs seven-axis CNC deep-hole drilling and milling machine to improve productivity.

Read MoreMassivit, Sika to co-brand digital tooling materials for Massivit 10000 series

Strategic MOU initially introduces SikaBiresin CIM 120 and SikaBiresin CIM 80 to serve crucial composites market needs for 3D printing tooling, prototyping and more.

Read MoreBelotti to integrate hybrid BEAD system with Adaxis AdaOne software

Through this strategic collaboration, BEAD’s additive and subtractive capabilities for large-scale AM composite tooling production are made more accessible.

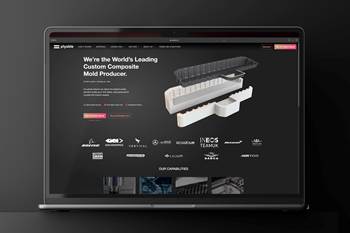

Read MorePlyable releases AI-powered mold design tool

Plyable continues to rid composites engineers of workflow bottlenecks through an end-to-end automated system — from mold design to quotation to manufacturing fulfillment.

Read MoreComprehensive group portfolio targets holistic engineering, tooling and epoxy resins

JEC World 2024: The RAMPF Group is bringing together three of its divisions — RAMPF Composite Solutions, RAMPF Tooling Solutions, and RAMPF Group Inc. — delivering a variety of materials and services to the composites industry.

Read MoreNational Composites announces partners with compression toolmaker Laval

The new alliance will broaden National Composites’ capabilities in SMC and BMC and tooling, while providing customers with comprehensive solutions, from initial design to final delivery.

Read MoreKnowledge Centers

This CW Tech Days event will explore the technologies, materials, and strategies that can help composites manufacturers become more sustainable.

LEARN MORE

Explore the cutting-edge composites industry, as experts delve into the materials, tooling, and manufacturing hurdles of meeting the demands of the promising advanced air mobility (AAM) market. Join us at CW Tech Days to unlock the future of efficient composites fabrication operations.

LEARN MORE

Review the state of the art in design, simulation, failure analysis, digital twins, virtual testing and virtual inspection.

LEARN MORELatest Molds/Tools News And Updates

Belotti retrofits Vega CNC center in BEAD hybrid machine for D-Composites

Combined LSAM and five-axis CNC milling capabilities will optimize D-Composites’ production services, flexibility and cut time and cost for composite tooling manufacture.

Read MorePRF Composite Materials granted U.K. patent for Q.tool

Innovative prepreg tooling is highly drapable, capable of forming complex carbon fiber tooling shapes, in addition to reducing through thickness porosity and only requiring one debulk during layup.

Read MoreORNL conducts sustainability analysis of 3D-printed composite molds

A comprehensive lifecycle, cost and carbon emissions study on carbon fiber molds, produced for New York’s concrete Domino building, cites economic benefits over wood alternatives.

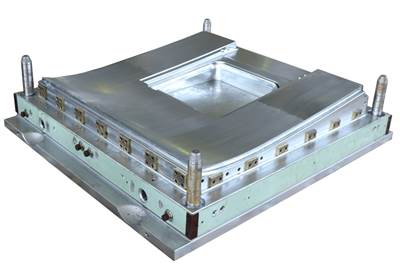

Read MorePrecision composite molds produce quality, reliable parts

CAMX 2023: Suase, under the Sanse Group, is presenting its design, development and manufacture of high-quality SMC/BMC/GMT/LFT molds for automotive, agriculture, construction, rail and more.

Read MoreAdvancing composite manufacturing through custom wire solutions

CAMX 2023: Pelican Wire’s engineering and manufacturing capabilities provide tailored wire solutions for complex heating, temperature monitoring and distinct sensing applications.

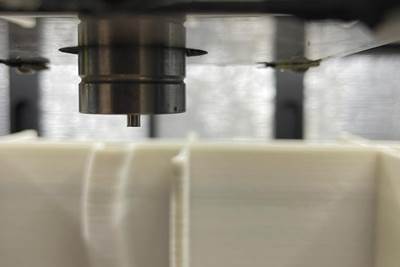

Read MoreTechnology investment contributes to complex industrial tooling services

CAMX 2023: A new five-axis router rounds out Accurate Patterns’ capabilities in precise toolmaking, patterns, plugs, fixtures and gauges for fiberglass fabricators, thermal formers, carbon fiber parts manufacturers and others.

Read MoreFeatured Posts

Mold 3D printing helps automate composite bathtub, shower production

As part of its efforts to automate as much of its production process as it can, Lyons Industries acquired a Massivit 10000 additive manufacturing system to quickly produce high-performance molds and support fixtures.

Watch3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

Read MorePlant tour: Airtech International, Springfield, Tenn., U.S.

Fifty years of supplying materials for composites manufacturing includes custom fabrication and now aims to advance 3D-printed tooling, parts and new resins.

WatchNine factors to consider when designing composites cure tooling

Gary Bond discusses the common pitfalls and compromises when designing good cure tooling and their holistic significance for a robust composite production process.

Read MoreProper application of semi-permanent mold release systems

Performing regular maintenance of the layup tool for successful sealing and release is required to reduce the risk of part adherence.

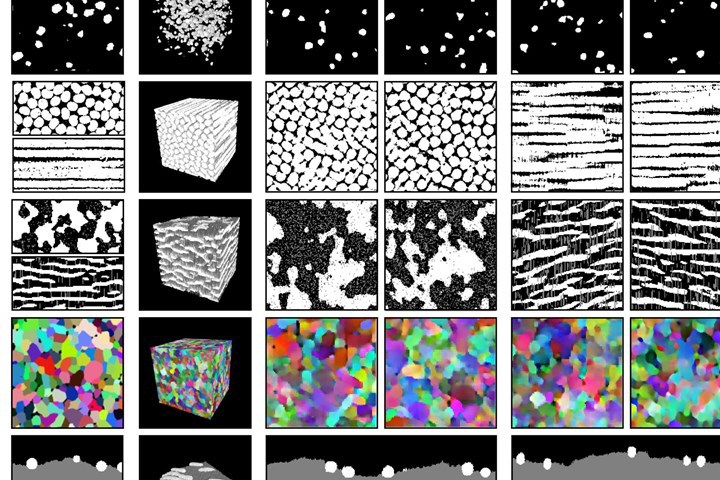

Read MoreMetal AM advances in composite tooling, Part 2

Toolmakers and molders continue to realize the benefits of additive versus conventional/subtractive manufacturing of molds and mold components.

Read More