AI inspection system with laser projection advances layup precision

CAMX 2025: Visit Virtek to learn more about the Iris Ai system with its new Results Projection feature in action, closing the loop between detection and resolution on the production floor.

Share

See laser projection paired with AI-powered inspection in action with Virtek Vision’s (Waterloo, Ontario, Canada) Iris Ai composite inspection system, which is designed to elevate quality control, reduce rework and streamline production in aerospace, automotive and other high-precision industries.

Iris Ai combines advanced edge-processing AI cameras with laser projection to detect what the human eye might miss such as backing paper and foreign object debris (FOD) in real time, without the need for additional programming. The system adapts to lighting and environmental changes, ensuring consistent, reliable inspections across complex parts and large surfaces.

New this year is Results Projection, a feature that visually displays inspection results directly onto the part using laser projection. This innovation enables operators to instantly see where FOD or other anomalies are detected, enabling faster corrective action and reducing downtime.

Key features behind Iris Ai include:

- AI-driven FOD detection in under 3 sec

- Live, real-time feedback to operators

- Results Projection directs users instantly to detection locations

- Automated image capture and full traceability by part serial number

- Seamless API integration with existing software for real-time production insights

- Scalable camera options for narrow and wide fields of view.

Using Iris Ai, every ply, orientation and timestamp is digitally recorded, creating a comprehensive audit trail that supports continuous improvement and compliance. Backed by Virtek’s customer support and global service network, Iris Ai is a partner in industry’s digital transformation journey.

Related Content

-

Xnovo Technology, Exciscope introduce X-ray tensor tomography technique

Through a strategic partnership, the companies introduce the FiberScanner3D module, dedicated to bringing more rapid, reliable and robust fiber structure characterization methods to lab settings.

-

Voidsy expands composites NDT&E into international markets, grows business capabilities

In efforts to transform into a stable, internationally recognized company for quality assurance and predictive maintenance, voidsy is looking for distribution and partnership opportunities outside the DACH region.

-

Shearography equipment well suited to composites NDT

CAMX 2025: Laser Technology Inc. features analysis tools like the LTI-2100 and LTI 5200, which are optimal for detecting subsurface composite flaws.

Related Content

Xnovo Technology, Exciscope introduce X-ray tensor tomography technique

Through a strategic partnership, the companies introduce the FiberScanner3D module, dedicated to bringing more rapid, reliable and robust fiber structure characterization methods to lab settings.

Read MoreVoidsy expands composites NDT&E into international markets, grows business capabilities

In efforts to transform into a stable, internationally recognized company for quality assurance and predictive maintenance, voidsy is looking for distribution and partnership opportunities outside the DACH region.

Read MoreShearography equipment well suited to composites NDT

CAMX 2025: Laser Technology Inc. features analysis tools like the LTI-2100 and LTI 5200, which are optimal for detecting subsurface composite flaws.

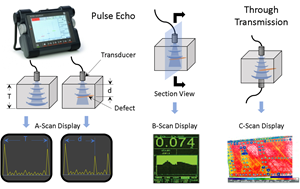

Read MoreNondestructive inspection methods available to composites manufacturers

An overview of composite laminate inspection techniques ranging from manual testing methods to more advanced, noncontact options.

Read MoreRead Next

Next-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read More