Injection/Overmolding

SPE ACCE 2018 preview

Mobility composites are expected to draw an international crowd to this annual Motor City gathering.

Read MoreMolding in fasteners to CFRP parts

Placed into the mold prior to RTM, compression or injection molding/overmolding, this specially-shaped fastener enables composites to be fastened with standard methods used for metal parts.

WatchComposite aircraft interiors market to exceed US$1.8 billion by 2023

According to Stratview Research, the aircraft cabin is one of the most discussed subjects in the airline industry today.

Read MoreOsborne Industries secures ISO 9001:2015 certification

International Organization for Standardization (ISO) 9001:2015 is currently the most up-to-date standard for performance of a manufacturer’s Quality Management System.

Read MoreSo, you want to overmold

If so, CompositesWorld is hosting, June 13-14, the Composites Overmolding conference, to explore the software, materials and processes being used to combine continuous fiber composites with overmolded thermoplastics.

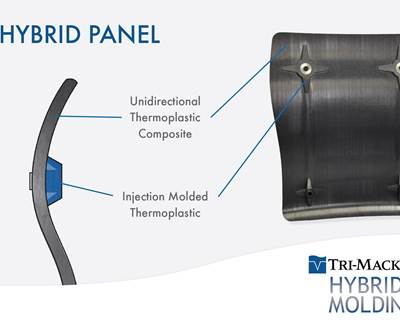

Read MoreJEC World 2018 preview: Tri-Mack Plastics

Tri-Mack Plastics Mfg Corp. is sharing the results of a recently completed test that demonstrates the bond strength of Tri-Mack’s overmolded thermoplastic composite hybrid parts.

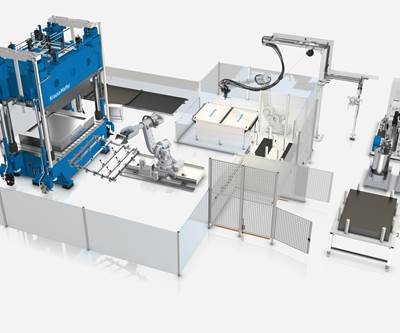

Read MoreJEC World 2018 preview: KraussMaffei

KraussMaffei (Hall 6, F61) is featuring several composites manufacturing technologies, covering wet molding, pultrusion, long fiber injection and overmolding.

Read MoreSGL Group optimizes supply chain for composites

SGL’s takeover of former BENTELER and BMW JVs, plus sale of Kumpers JV, consolidates the company’s CF activities while it broadens its composites technology portfolio.

Read MoreCore Molding acquires HPI

Core Molding Technologies, a compounder of custom sheet molding compound and molder of fiberglass-reinforced plastics, has acquired substantially all of the assets of Canada-based Horizon Plastics International Inc.

Read MoreOvermolding as enabler for composites, aerospace to automotive

CCP Gransden can make 50 to 100,000 parts/yr economically viable using PEEK, PPS, PEI or PA.

Read More

.jpg;maxWidth=300;quality=90)