XlynX Materials introduces PFAS-free BondLynx molecular adhesive

Improved version of BondLynx eliminates fluorine for a more sustainable adhesive option, while still outperforming conventional adhesive bonding strength.

Dr. Rashid Nazir speaks to the development of this new version of BondLynx BXW-202. Photo credit, all images: XlynX Materials

XlynX Materials (Victoria, Canada) announces the redesign of its flagship molecular adhesive, BondLynx, a commercial crosslinker capable of bonding non-functionalized polymers. BondLynx BXW-202, rebuilt from the ground up, now eliminates fluorine from its chemical structure. The result is an adhesive that is reported to be safer for the environment, more stable for storage and more cost-effective for customers.

Unlike traditional adhesives that rely on mechanical forces to hold materials together, BondLynx employs bis-diazirine technology to create covalent bonds between polymer chains, permanently crosslinking them through strong carbon-carbon bonding. Originally designed to bond “unbondable” low surface energy plastics like polypropylene (PP) and polyethylene, BondLynx has since found applications as a surface functionalizing agent, an additive in microelectronics fabrication, a performance textile strengthener and a molecular stabilizer for perovskites, quantum dots and organic electronics.

Until now, fluorine — one of the most reactive elements in the periodic table — was considered a critical component of bis-diazine crosslinking. But with the tide turning against the use of PFAS chemicals, the development of a suite of fluorine-free products was the company’s top priority.

“With all we now know about the persistence of PFAS chemicals in the environment, it was important for us to get ahead of the problem and be a part of the solution,” XlynX director of strategy, Sean Bourquin, states. “Our clients have been telling us the same thing. This issue is on everyone’s radar these days, so we knew we had to find a new formula for BondLynx.”

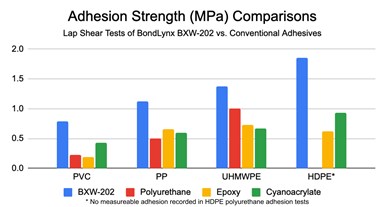

To accomplish this goal, the R&D team at XlynX Materials went back to the drawing board to create a version of BondLynx that did not depend on fluorine. While details about the designed solution have not been revealed, senior research chemist Dr. Rashid Nazir reports that test results for the new molecular adhesive have exceeded expectations. In comparative lap shear adhesion tests with conventional polyurethane, cyanoacrylate and epoxy adhesives, BondLynx BXW-202 outperformed the competition in every category, including:

- 70% to 124% stronger adhesion for PP

- 84% to 316% stronger adhesion for polyvinyl chloride rubber

- 100% to 200+% stronger adhesion for high-density polyethylene (HDPE)

XlynX Materials is now capitalizing on its platform technology to design a suite of PFAS-free crosslinkers for specific substrates and client applications. The company encourages new and existing clients to reach out for information on how BondLynx BXW-202 can address their manufacturing needs, unlock new opportunities and support their move towards a more sustainable future.

Related Content

-

Henkel releases digital tool for end-to-end product transparency

Quick and comprehensive carbon footprint reporting for about 58,000 of Henkel’s adhesives, sealants and functional coatings has been certified by TÜV Rheinland.

-

CAMX 2022 exhibit preview: Click Bond

Click Bond develops lightweight fasteners for assembly technology that require no installation holes, preserve structural integrity and are easy to install.

-

Materials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.