Rope Robotics automates onshore wind turbine blade repairs

Patented robot uses visual sensors to diagnose any potential damage for remote operators, and initiates a repair process in real time that is four times faster than manual alternatives.

After more than 18 months in operation, having repaired 150+ rain-damaged onshore wind turbine blades in the U.S., Canada, South Africa and Europe, the patented “BR-8” robot from Rope Robotics (Aarhus, Denmark), has demonstrated return on investment (ROI) for wind turbine owners within just six months. Compared to manual alternatives, the robot can repair the blade around four times faster at half the cost, the company contends.

An increasing problem, rain erosion damage compromises aerodynamic performance of the blade and, at worst, can lead to blade failure and expensive turbine downtime. The repairs offered by Rope Robotics is said to not only restore turbine power output but are quick, cost-effective and efficient as well as safe for technicians to perform in all but the most inclement weather conditions. Previously, technicians have had to abseil from the nacelle to the blade and work with harmful chemicals, a high-risk work environment that is weather-dependent and costly. Moreover, leading-edge repair accounts for some 25-30% of the build cost of the wind turbine.

“Rain erosion is an already serious and worsening issue with the longer rotor blades generating tip speeds of over 380 kilometers per hour,” Martin Huus Bjerge, CEO, Rope Robotics, explains. “Rain drops at that speed act like a hail of bullets that, over time, damage the leading edge of the blade.”

Rope Robotics’ “BR-8” robot can restore up to 3% energy output within less than one day per blade at half the cost of manual solutions, the company says. In addition to its aforementioned commercial operations, Rope Robotics is applying results from onshore repairs in countries like Denmark, Sweden and Germany — the information received will better inform in-progress test repairs on offshore turbines, in preparation for a commercial launch scheduled at the end of 2023.

After leading-edge damage has been established, typically by drones, the wind farm or service provider contracts Rope Robotics, who supplies the robot along with technician training and support on site.

The core of the system is a robot carrying visual sensors, which operates repair tools using a flexible arm, with technicians monitoring the robot from any location, on site or remotely.

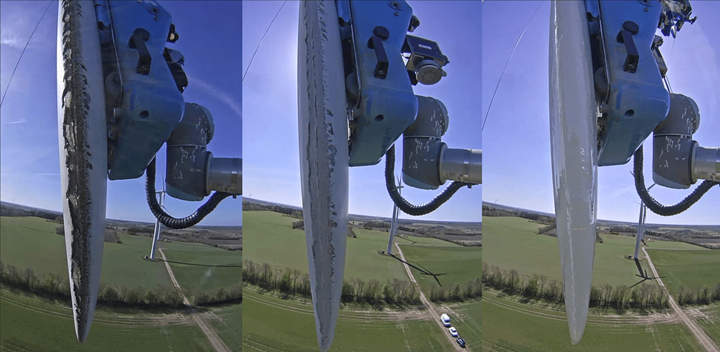

On site, the 150-kilogram robot is first attached to ropes that have been anchored in the nacelle before it is hoisted some 100 meters from the ground onto the damaged blade, which has been fixed in a vertical position. A vacuum system enables the robot to attach itself firmly while motors provide movement across the blade. Using its onboard high-resolution camera and laser scanner, the robot inspects the surface, sending images to the remote operator, who diagnoses the damage and initiates the repair process in real time.

The three-phase repair process starts with sanding the damaged area, applying appropriate speed and force to create a pattern ensuring surface roughness and geometry. A second tool cleans the surface using a brush and alcohol to remove dirt and grease. The patented dosing tool applies the leading-edge protective (LEP) material while the spreader tool, also patented, rebuilds the optimal aerodynamic blade shape, smoothing the material to pre-defined standards.

Controlled remotely on-screen by a technician viewing live images, Rope Robotics says the robot performs each step with high precision and consistency, thus ensuring quality. All images are recorded and serve as documentation, a global requirement for wind turbine maintenance.

Awarded two patents covering the robot system, the method, the spreading tool and the dosing tool, the robot took five years to develop and was launched in 2021. The robot has been proven in the field at wind speeds of up to 14 meters per second, relative humidity of up to 80% and temperatures from 0-40ºC. Using results received from other blade repairs, Rope Robotics says it is investing in artificial intelligence (AI) to offer autonomous repairs in the future.

Related Content

Broetje-Automation demonstrates rCF placement via AFP

Through the ScrapSeRO project, the system integrator and machine builder successfully processed recycled composites, in addition to more traditional materials, via its highly flexible Staxx One system.

Read MoreAES explores robot vs. gantry for large-format additive manufacturing

Additive Engineering Solutions, specialist at 3D printing very large parts and tools on gantry machines, now also uses a robot for large-format AM. Here is how the robot compares.

Read MoreHow AI is improving composites operations and factory sustainability

Workforce pain points and various logistical challenges are putting operations resilience and flexibility to the test, but Industry 4.0 advancements could be the key to composites manufacturers’ transformation.

Read MorePlyable releases AI-powered mold design tool

Plyable continues to rid composites engineers of workflow bottlenecks through an end-to-end automated system — from mold design to quotation to manufacturing fulfillment.

Read MoreRead Next

Ultrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read MoreScaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read More