Dieffenbacher automates SMC lines for enhanced productivity and efficiency

Quick-change cutting system reduces changeover times to six to seven minutes, and ensures maximum reproducibility, even with the complex geometries.

Photo Credit: Dieffenbacher

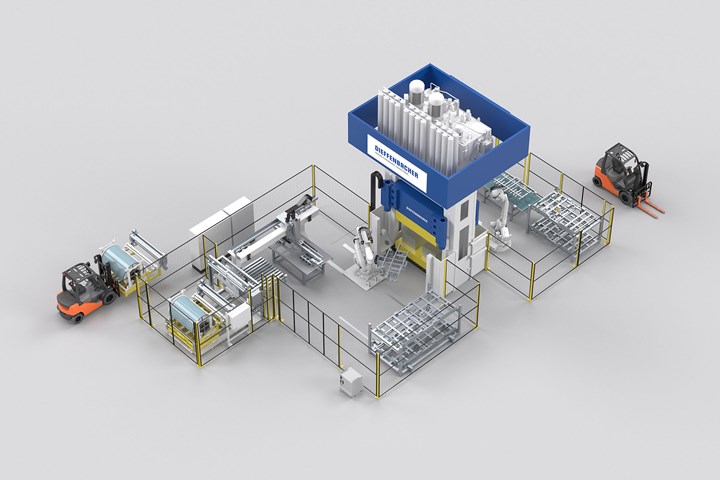

Dieffenbacher (Eppingen, Germany) has fully automated its sheet molding compound (SMC) lines to enable short cycle times, reduced scrap costs, increased output and an overall boost in productivity and plant efficiency, particularly as parts suppliers for the automotive, logistics and construction industries are increasingly turning away from manual operations.

According to Marco Hahn, director of sales for Dieffenbacher’s Composites Business Unit, with conventional cutting systems, a change of SMC input material takes about 10 minutes, causing constant production interruptions. In contrast, the Dieffenbacher quick-change system is said to save about six to seven minutes each time a user changes the SMC batch, by allowing the material to be changed parallel to ongoing operation. Prepared outside the production cell, the quick-change device with the new SMC batch is moved into the plant cutting system at the push of a button and automatically inserted as soon as the previous batch has been used.

Further, the Dieffenbacher SMC lines are equipped with automated cutting peripherals that communicate automatically with a stacking portal, enabling several complex layup profiles with different cutting patterns to be produced simultaneously. Active-compensation cutting automatically corrects deviations in stack weight, and weight tolerances in the semi-finished product are said to be reliably met. This ensures maximum reproducibility, even with the geometric complexity of the SMC layer structure, the company reports.

Automation offers other benefits, says Dieffenbacher. Flexible cutting geometries also make optimum use of the input material and minimize waste, protecting the environment and reducing disposal costs.

Related Content

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

-

Materials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

-

A new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.