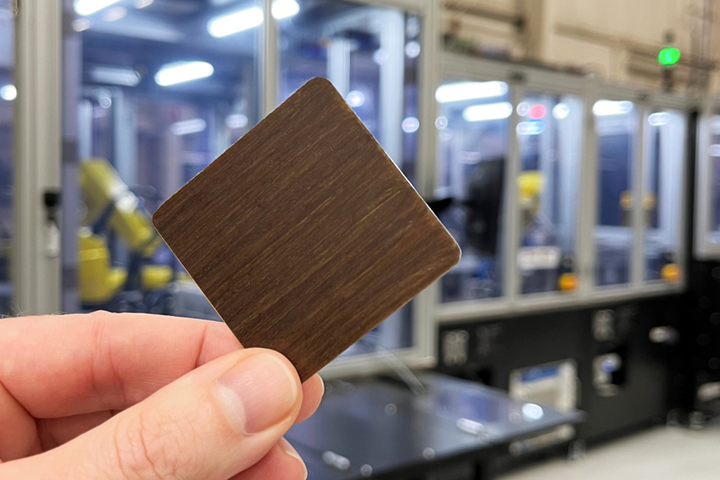

Arris unveils structural flax fiber composite

High-performance natural fiber adds to the company’s other biocomposite offerings, helps achieve sustainability initiatives.

Photo Credit: Arris

Arris (Berkeley, Calif., U.S.) announces a new sustainable flax fiber composite material offering for structural applications, with high-performance capabilities to complement its already available bio-nylon resin material being used with carbon and glass fibers. Flax has <5% of the CO2e footprint compared to carbon fiber, aiding in emissions reduction.

Sustainability and innovative material development are at the core of everything Arris does as the team scales Additive Molding for a production capacity in the millions to meet demand. Additionally, Arris says it has doubled its in-house material production capacity as of February 2023 to support growing customer programs.

“Since we started, our R&D team has been researching and investigating recycled, recovered, and natural fibers, as well as recycled, bio-based and bio-synthesized polymers that help brands achieve necessary sustainability initiatives without sacrificing the best-in-class performance their customers have come to expect,” Bert Mannhalter, Arris vice president of research and development (R&D), says. “I’m excited to reach this breakthrough in processing flax fibers. Though it’s been used for cosmetic parts such as veneers and paneling, we now see a way to use these fibers for true structural applications.”

Related Content

-

RUAG rebrands as Beyond Gravity, boosts CFRP satellite dispenser capacity

NEW smart factory in Linköping will double production and use sensors, data analytics for real-time quality control — CW talks with Holger Wentscher, Beyond Gravity’s head of launcher programs.

-

Thermoset-thermoplastic joining, natural fibers enable sustainability-focused brake cover

Award-winning motorcycle brake disc cover showcases potential for KTM Technologies’ Conexus joining technology and flax fiber composites.

-

Augmenting engineered thermoplastics with natural fibers

The Paris Climate Accord mandate for net-zero carbon by 2050 has kick-started an innovation revolution for natural fibers and sustainably engineered resins.