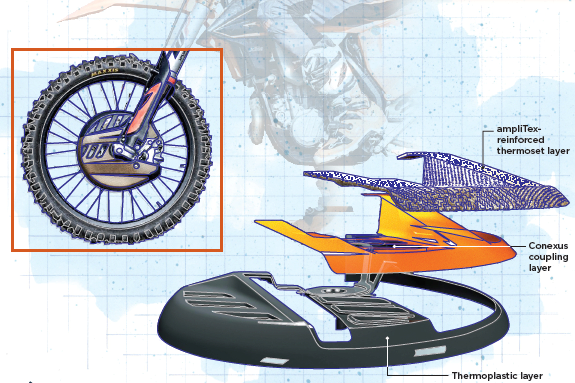

Showing off multi-material joining, natural fiber composites. With three iterations in development and poised to go on the market, KTM Technologies’ new motorcycle brake disc covers demonstrate potential for its Conexus joining technology to combine thermoset parts with thermoplastics. Photo Credit, all images: KTM Technologies

“Sustainability” was the official theme of the JEC World 2022 exhibition in Paris, France. One project that exemplified this theme, and that took home the 2022 JEC Innovation Award in the Sports, Leisure and Recreation category, is a motorcycle brake disc cover that aimed to demonstrate three sustainability-focused technologies in one part.

The cover, a circular panel designed to mount to the wheels of a racing motorcycle to protect the brake system from debris or impact, was entered into the competition by flax fiber supplier Bcomp Ltd. (Fribourg, Switzerland) and built by KTM Technologies (Salzburg, Austria), the R&D and innovation unit of motorcycle manufacturer KTM AG (Mattighofen, Austria).

The part combines three technologies: a compression-molded flax fiber/epoxy base structure, an injection overmolded thermoplastic outer layer and an innovative technology to join the two layers together without the use of adhesives.

Stefan von Czarnecki, director of sales and business development at KTM Technologies, explains that the entire company is emphasizing sustainability initiatives, including manufacturing, part design and end-of-life (EOL) solutions, starting with R&D initiatives aimed to qualify and evaluate opportunities for series production. One of these initiatives was the creation of an innovative joining technology called Conexus, which the award-winning brake cover was designed to demonstrate.

Illustrated by Susan Kraus.

Conexus: Adhesive-free, multi-material joining solution

Thermoset composite parts — in motorsports and many other end markets — are often combined with parts made of other materials, such as unreinforced plastic or metal. Multi-material joining with thermoset composites generally involves either mechanical fasteners, which add weight to the part, or adhesives. In addition to adding weight, the latter includes chemicals that are generally not considered to be sustainable, and often requires pre-treatment and a challenging process and quality control due to stringent nondestructive testing standards.

Conexus layering. Conexus technology was developed to be a thermoplastic coupling layer in between a molded thermoset component and a thermoplastic material, integrated via 3D printing or injection overmolding.

KTM Technologies sought a joining solution that would avoid the use of fasteners and adhesives. The basis of the Conexus technology that KTM ultimately developed over the past few years is a thermoplastic film — called a “coupling layer” — that can be added to a traditional thermoset composite layup in a curing process, such as, in this case, prepreg compression molding. During the cure process, the Conexus layer bonds to the thermoset composite part, acting as a chemical release agent and serving as an outer, unreinforced thermoplastic layer onto which the thermoplastic material can be directly joined. “You can then functionalize the part by injection molding, 3D printing or welding,” explains Michael Heider, lead engineer at KTM Technologies. Conexus can also be used with a variety of resin and fiber types.

The brake cover: Carbon fiber first

Testing material samples. Before proving out its technology on its brake disc covers, KTM started with coupon-level testing of Conexus on a range of fibers and plastic part combinations.

The brake disc cover project originated as a way to demonstrate the Conexus technology, and is in serial production at KTM as a carbon fiber/epoxy version that features a metal insert directly joined to a thermoplastic component via injection molding. Based on this serial part and the processes and tools used to manufacture it, the more sustainable flax fiber/epoxy demonstrator presented at JEC World was built.

Heider explains, “We were looking for a semi-structural part to showcase the feasibility that the connection is working on the same level as a structural adhesive. The brake cover was chosen because it’s a very visible part on the motorcycle.”

KTM’s industrial design department began with technical specifications for one of the company’s standard brake disc covers. Generally, these covers are made from metal or injection molded plastic, and include several holes to allow airflow to the brake disc underneath. Metal inserts fit into the bottom of the cover to enable the cover to mount and latch to the bike.

With the new design, the goal was to develop a part with three layers. The top outer layer would be an epoxy thermoset-based composite to increase the overall impact resistance and stiffness of the part, and a bottom layer would be unreinforced thermoplastic that would be fitted with the metal insert, with the Conexus coupling layer in between joining the two halves together, acting as the third layer. The thermoset and thermoplastic layers ultimately overlap slightly — “but this isn’t for connecting,” Heider explains. The overlap protects the edges from moisture and wear over time.

First iteration: Carbon fiber/epoxy. The initial carbon fiber/epoxy brake disc cover successfully proved out the technology for end-use parts. From there, KTM Technologies went back to the drawing board to use even more sustainable materials.

The design team began with CAD files of the existing design and used digital simulation to design a new part, with the goal of incorporating the right materials in the right place. Additional simulations were performed to help avoid warping and assure good filling and temperature distribution for the coupling layer during the injection molding process.

“Design for manufacture was key,” Heider notes. To be able to serially produce the covers, the manufacturing process had to be relatively fast, with part costs as low as possible. “We knew we wanted to produce an attractive optical part and give visibility to the hybrid construction, but we also needed a part that can be produced using known and approved processes, to give us the opportunity to make parts very quickly and efficiently,” he explains.

For speed, compression molding was chosen for the thermoset part, and injection molding for the thermoplastic part. “We designed the process for easy processability and low scrap,” Heider adds.

The original design of the cover involved a compression molded, carbon fiber/epoxy top layer joined via Conexus to an injection molded bottom layer made from a blend of polyamide 6 (PA6) and ABS (acrylonitrile butadiene styrene) from INEOS Styrolution (Frankfurt, Germany). KTM Technologies developed tooling for the thermoset part with partner Alba Tooling & Engineering GmbH (Forstau, Austria), and for the injection molding tool with Altendorfer Kunststofftechnik GmbH (Neureichenau, Germany).

First, the thermoset composite layer is formed via compression molding. During layup, a single layer of the Conexus film, about 100 microns thick in the final part after processing, is applied as the bottom layer in the mold. The Conexus layer uses a copolymer that works with the selected thermoplastic and thermoset — in this case, epoxy and polyamide — to join them together. Additionally, the Conexus layer acts as a release film in the tool. The carbon fiber fabric is then added on top, and subsequent molding at 150°C (302°F) creates a bond between the thermoset and Conexus layer. After molding, the part and a central metal insert are transferred to an injection molding station, where the PA6/ABS layer is injection overmolded directly onto the Conexus film, creating an additional bond between the coupling layer and thermoplastic.

“We don’t need a gluing step, or rivets or bolting or screwing. Directly out of the injection molding process we have a part that we can directly mount to the motorcycle,” Heider says.

A more sustainable, flax fiber version

The carbon fiber version of the cover was a successful demonstrator of the Conexus technology, Heider says, but “one of our goals is to reduce the overall carbon footprint of our components, so we thought next about how to make a more sustainable version. As a first step, we decided to replace the carbon fibers since it was the material with the highest CO2 footprint.”

KTM had worked with flax fiber supplier Bcomp on motorsports projects in the past, so a trial version of the cover using Bcomp materials felt like an obvious next step.

First, the two companies went back to the drawing board to perform coupon-level testing on an identical version of the carbon fiber/epoxy component, this time using Bcomp’s ampliTex 5040 300-gsm twill flax fabric combined with epoxy and a Conexus layer via compression molding. Again, this was followed by an injection overmolded PA6 bottom layer. A series of tests were done to prove that the flax fiber was compatible with the Conexus technology and that the combined parts would stay joined over time and in a variety of conditions. Heider notes that although the overall mechanical performance of the flax fiber is lower than that of carbon fiber, the material offers advantages like improved damping behavior, and that it does not splinter when broken, increasing safety.

Once validated at the coupon level, the same tooling and part design as the original carbon fiber cover were used to manufacture new demonstrator covers.

Flax fiber/epoxy and flax fiber/bio-based PA. For its second and third iterations of the brake disc cover, KTM Technologies used Bcomp flax fiber with epoxy (shown here) and flax fiber with a bio-based polyamide. Both versions of the cover won awards in 2022.

For the carbon fiber-reinforced polymer (CFRP) and flax fiber covers, KTM Technologies ultimately demonstrated the technology on in-house specimen- and part-level tests to prove adhesion for the joined parts, impact resistance, UV resistance and more, according to the company’s internal quality standards. “Our parts go directly onto the motorcycle where they’re tested by actual riders,” Heider says. “We do mechanical tests on the component separately, then test real-world performance on the motorcycle.”

The real-world testing is key, von Czarnecki notes. “You can predict or simulate a lot of scenarios but there are a range of situations — impacts, weather events, stone chipping — that you can’t guess.”

According to Heider, the CO2 footprint of the materials is reduced by up to 60% by switching to flax fiber from carbon fiber. “We wanted to show that we can use our Conexus technology to produce aesthetic and performance parts on the one hand, and to be able to fulfill sustainability targets on the other hand. By using established manufacturing methods where we can easily implement other fibers or thermoplastic materials, we have an innovative joining technology ready for the market, which can adapt easily to the needs of every customer without the necessity to invest in additional machinery,” Heider says.

Next: Flax fiber and bio-based resin, scale-up

The JEC Award-winning flax fiber/epoxy part was only the first step toward demonstrating the use of sustainable materials for brake disc covers. In October 2022, KTM Technologies was awarded an SPE (Society of Plastics Engineers) Automotive Award in the “Body Exteriors” category for a new version of the cover that uses flax fiber in combination with a bio-based glass-filled polyamide.

For this part, KTM Technologies partnered with Akro-Plastic GmbH (Niederzissen, Germany), a company that specializes in plastic compounds and that recently introduced a product line of bio-based thermoplastics. Again, the teams began by testing materials at the coupon level, and for the SPE-presented part, decided to demonstrate the brake disc cover using Akro-Plastic’s Akromid Next 5.10 3 GF 30 glass fiber-filled PA6, chosen for its high bio-based content and higher mechanical properties due to the additional glass fiber. This version of the brake disc cover is said to enable up to 70% CO2 reduction for the materials used compared to the series model.

Of the overall process, von Czarnecki explains, “We start our parts basically as a demonstrator as a first step, then to small series application, then to higher volumes. This is how we enable and qualify new technologies for the company and then scale it up.”

The carbon fiber version of the brake disc cover is now available for the aftermarket and will be equipped on some special edition motorcycles beginning in 2023. About 5,000 CFRP covers will be produced annually for KTM’s MX and enduro full-size models, Heider says. The company says the natural fiber cover may be introduced into KTM’s PowerParts portfolio as an aftermarket option once tests are completed.

“The strategy driving the whole process on our side was to enable us to use these materials together, and to use each material for what it does best,” von Czarnecki explains. “That is, to use the thermoset for the mechanical properties where they were needed, and where the customer can see it to really appreciate [the flax fiber], and to use thermoplastic for functions such as ribs and integration of inserts, and by this we achieve the most cost-efficient design.”

End of life: Recycling vs. energy recuperation

In addition to demonstrating natural fiber materials, thanks to the Conexus coupling layer, the flax fiber composite cover “has a drastically reduced global warming potential, and a very nice end-of-life scenario compared to the carbon fiber version,” Heider says.

The Conexus coupling layer is designed to have a lower melting temperature than the thermoplastic part in a given application, he explains. At the part’s EOL, if heat is introduced at the coupling layer’s melting temperature, the Conexus layer will melt and allow the thermoset and thermoplastic parts to be easily separated without damaging or melting either part.

In this case, the thermoplastic component could then be melted and reformed for additional uses, while the flax fiber component would ideally be pyrolyzed, with the energy recaptured for another use such as cement kiln coprocessing or waste-to-energy cogeneration plants.

Why not recycle or repurpose the flax fiber thermoset component? Johann Wacht, manager of motorsports and supercars at Bcomp, explains, “With recycling, you need to think about your base materials.” He claims that the company’s flax fiber materials are produced as CO2-negative materials, whereas any of today’s recycling methods would consume energy and result in a larger overall carbon footprint. “In this case, simply recovering energy from the natural fiber and epoxy [at the part’s EOL] is the better solution, because you can recuperate 80% of the energy stored in the material. It makes a lot of sense from a CO2 footprint perspective.”

However, with the carbon fiber version of the brake disc cover, “it’s another game,” Wacht says, “because carbon fiber is very energy-intensive to produce. Carbon fiber makes absolute sense to recycle.” Depending on the specific recycling method, the energy consumption that goes into recycling carbon fiber generally still results in a lower overall carbon footprint for the material, he notes.

Heider notes that the Conexus technology both assures a strong chemical bond between the thermoplastic and thermoset materials involved, and, because it is thermoplastic-based, enables separation at the correct temperature.

Future applications: Urban air mobility and more

Production-ready. KTM Technologies plans to produce its carbon fiber and flax fiber composite brake disc covers commercially. Beyond motorsports, the company plans to use its now-proven Conexus technology for automotive and even urban air mobility (UAM) applications in the future.

The brake disc cover project, and motorsports in general, is only the first step for Conexus technology, says von Czarnecki. “This enables the possibility to combine materials without bonding, increasing sustainability and reducing complexity in the process. It is offering a whole new range of applications.”

Currently, KTM Technologies is investigating several racing motorsports projects and exterior automotive non-structural parts using the Conexus technology. In addition, as demonstrated in a joint research project with Airbus’ Composite Technology Center (CTC, Stade, Germany) which focused on the use of Conexus technology with ultrasonic welding (see video below for a demonstration of this technology), one goal for Conexus is to enable smart and efficient manufacturing in emerging industries such as advanced air mobility (AAM).

Von Czarnecki emphasizes that the process and technology haven’t only been designed for use by KTM itself. “Our strategy is to qualify the technology and de-risk it for ourselves, and then enable our production partners to use it in other industries,” he says.

This project also demonstrated natural fiber composites as a good fit for Conexus. Von Czarnecki notes, “Expecting carbon fiber shortages, the Conexus technology offers an opportunity to use less carbon fiber on one side [of the part] and more natural fiber on the other — still light and cost-efficient.”

For Bcomp, Wacht says that this project has been “a perfect example to show the design freedom you have thanks to this process. When you think about the potential of this technology, you can see how it could be used for an even more complex shape, such as in a supercar interior or in larger bodywork components.”

Related Content

Airbus works to improve the life cycle of composites in future aircraft

This companion article to CW's September 2024 Airbus Illescas plant tour discusses recycling, LCA, biocomposites, Fast Track technologies, qualification and more.

Read MorePlant tour: Hexagon Purus, Kassel, Germany

Fully automated, Industry 4.0 line for hydrogen pressure vessels advances efficiency and versatility in small footprint for next-gen, sustainable composites production.

Read MoreComposites end markets: Sports and recreation (2025)

The use of composite materials in high-performance sporting goods continues to grow, with new advancements including thermoplastic and sustainability-focused materials and automated processes.

Read MoreASCEND program completion: Transforming the U.K.'s high-rate composites manufacturing capability

GKN Aerospace, McLaren Automotive and U.K. partners chart the final chapter of the 4-year, £39.6 million ASCEND program, which accomplished significant progress in high-rate production, Industry 4.0 and sustainable composites manufacturing.

Read MoreRead Next

JEC World 2022, Part 2: Recycling, natural fibers and additive manufacturing

CW associate editor Hannah Mason recaps several technologies seen on display at JEC World 2022, including new developments from Bcomp, Massivit 3D, Gen 2 Carbon and more.

Read MoreThermoplastic composite structure replaces metals on safety-critical brake pedals

First all-composite brake pedals developed by Boge Rubber & Plastics Group are lighter, stiffer, stronger and offer improved driving haptics.

Read MoreScaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg)