AnalySwift improves simulation of composite helicopter, air mobility blades and other slender structures

VABS 4.0 now enables users to evaluate cross section strength and safety under given loads.

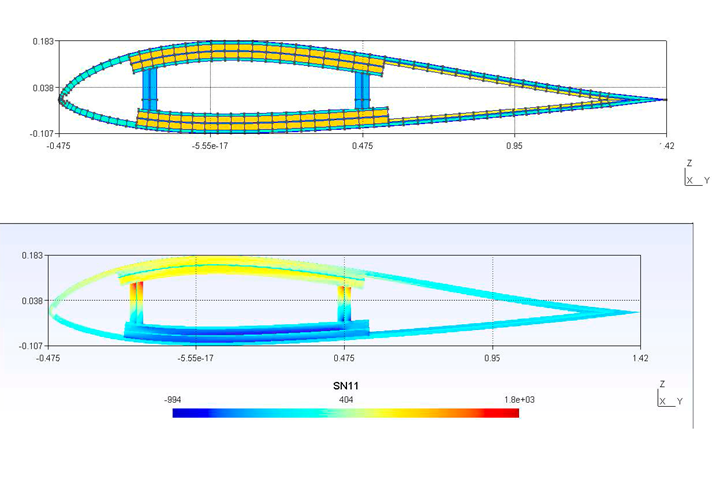

Air foil meshed cross-section viewed in Gmsh and Contour plot of recovered nodal stress SN11. Photo Credit: AnalySwift

AnalySwift LLC (West Lafayette, Ind., U.S.) has released the newest version of VABS, the company’s general-purpose composite blade modeling software. Originally developed to address the challenge of quickly and accurately modeling complex helicopter rotor blades, the VABS software has rapidly found applications for wind turbines, urban air mobility (UAM), landing gear, industrial tubes and golf clubs.

VABS 4.0 can now perform the following capabilities, in addition to existing ones critical to modeling slender shapes made from composites:

- Compute point-wise distributions of failure indexes and strength ratios over the cross section under given load.

- Compute the safety margin of the cross section under a given load.

- Output the nodal stress/strain values according to the original numbering of the finite element nodes.

- Output the complete set of engineering properties commonly used in conventional beam analysis including extension stiffness (EA), torsional stiffness (GJ), principal bending stiffness (EI22; EI33), principal shear stiffness (GA22; GA33), tension center, shear center, principal inertia axis, principal bending axis and principal shear axis.

VABS is a cross-sectional analysis tool for predicting structural properties and 3D stresses/strains/failure status of slender composite structures. It is able to compute all composite rotor blade properties efficiently and accurately using composite beam theory, which can handle arbitrary sections and calculates the most accurate beam properties and layer-wise 3D stresses/strains/failure status.

Related Content

-

3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

-

Thermoset-thermoplastic joining, natural fibers enable sustainability-focused brake cover

Award-winning motorcycle brake disc cover showcases potential for KTM Technologies’ Conexus joining technology and flax fiber composites.

-

Protecting EV motors more efficiently

Motors for electric vehicles are expected to benefit from Trelleborg’s thermoplastic composite rotor sleeve design, which advances materials and processes to produce a lightweight, energy-efficient component.