U.K. companies join Team Tempest project to advance future air combat

Bombardier, GKN Aerospace, and more have signed agreements to progress design, manufacture and operation of the U.K.’s combat air system technologies.

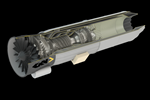

Source | GKN Aerospace

It was recently reported that seven U.K. companies have signed agreements to progress opportunities to contribute future combat air concepts and underpinning technologies to the Team Tempest project, a collaboration between BAE Systems (Farnborough, U.K.), Leonardo (London, U.K.), MBDA (Stevenage, U.K), Rolls-Royce (London, U.K.) and the UK Ministry of Defence, to develop game-changing technologies at an affordable pace and manner. The companies involved include Bombardier (Belfast, Ireland); Collins Aerospace in the U.K.; GE Aviation (Eastleigh, U.K.); GKN Aerospace (Redditch, U.K.); Martin-Baker (Uxbridge, U.K.), QinetiQ (Farnborough, U.K.); and Thales U.K. (Belfast, Ireland). It is said that the additional expertise represents a significant step forward.

GKN Aerospace notes that the companies will now seek opportunities to join forces on established projects and developments with the core Team Tempest partners, bringing the best of British expertise and ingenuity to designing, manufacturing and operating combat air systems.

“This announcement demonstrates further progress in delivering the U.K.’s combat air strategy, with more companies collaborating on the future of the U.K.’s air defense,” says Jeremy Quin, the U.K. Minister for defense procurement. “This is a highly innovative project based around cutting-edge technology and drawing on a skills base where the U.K. excels in. I am delighted that the success and strengths of Team Tempest are being enhanced through working with industrial partners and a highly capable international team.”

Collectively, the companies will look to support more than 60 technology demonstration activities currently underway, which is said will demonstrate and de-risk world-leading processes and technology in half the time and at significantly lower cost than previous complex combat air programs.

Related Content

-

Scaled Composites Model 437 aircraft to be flown for Beacon autonomy testbed

Northrop Grumman subsidiary part of Digital Pathfinder development of stealth aircraft with wings using continuous carbon fiber additive manufacturing and determinate assembly.

-

MATECH C/ZrOC composite is deployed in hypersonic aeroshells

Ultra high-temperature insulating CMC targets hypersonics, space heat shields and other demanding applications, tested up to 2760°C under extreme stagnation pressures.

-

Carbeon C/C-SiC ceramic matrix composites without fiber coating

Dutch startup Arceon is working with leaders in space, hypersonics and industry to test its Carbeon CMC, validating near-net-shape parts with <3% porosity and performance at 1600ºC, targeting UHTCMC and a presence in the U.S. in 2025.