Teijin aramid, carbon fibers used for museum façade panels

The new wing of the Stedelijk Museum Amsterdam is the first and largest composite building constructed from Teijin’s Twaron and Tenax fibers.

Source | Teijin

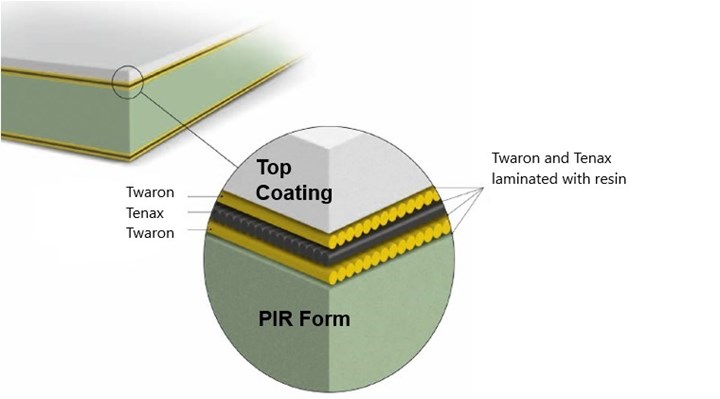

The Teijin Group (Tokyo, Japan) announced that its Twaron para-aramid fiber and Tenax carbon fiber were used to build 185 composite panels for the façade and canopy of a new wing of the Stedelijk Museum Amsterdam (Amsterdam, Netherlands). Measuring 100 meters by 25 meters, it is the world’s first and largest-scale composite building using Twaron and Tenax, Teijin says.

The new wing of the museum is known as the “bathtub” due to its distinctive shape. Twaron para-aramid fiber produced by Netherlands-based Teijin Aramid B.V. and Tenax carbon fiber produced by Teijin Carbon Europe GmbH in Germany were combined with vinyl ester resin in composite laminates, forming the outer skins of a composite sandwich construction with a core of PIR foam. Twaron and Tenax fibers are said to contract as temperature rises, unlike expanding resins, reportedly ensuring minimal thermal expansion of the panels while offering structural stability.

Source | Teijin

The Teijin Group has been sponsoring the Stedelijk Museum Amsterdam since 2007, as a cultural initiatives based on the company’s corporate philosophy to grow and evolve in harmony with society. Teijin is sponsoring the Colorful Japan exhibition, which opens Sept. 7, to emphasize the strong bonds between Japan, Teijin and the Netherlands.

Related Content

-

Plant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

-

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

-

Otto Aviation launches Phantom 3500 business jet with all-composite airframe from Leonardo

Promising 60% less fuel burn and 90% less emissions using SAF, the super-laminar flow design with windowless fuselage will be built using RTM in Florida facility with certification slated for 2030.

.jpg;width=70;height=70;mode=crop)