Rock West Composites completes composites-intensive EOI Space telescope structure

Delivery of mirror mountings and stress-free module support meets LEO constellation optical payload requirements within six-month design, analysis and fabrication schedule.

Share

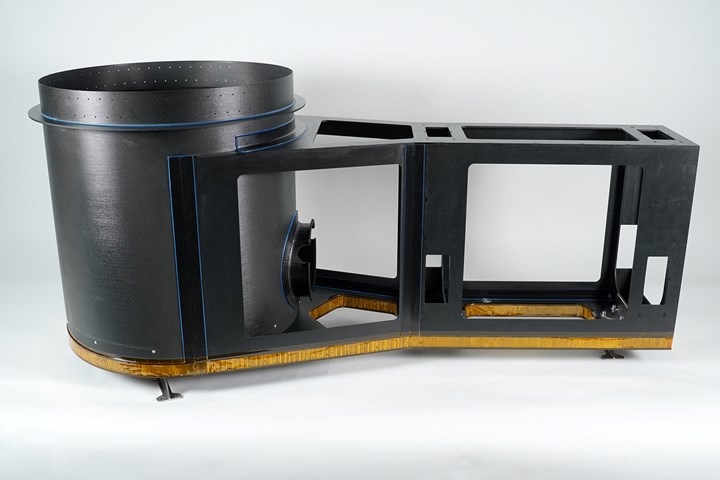

Large aperture telescope structure delivered to EOI Space. Photo Credit, all images: Rock West Composites (RWC)

Rock West Composites (RWC, San Diego, Calif., U.S.) announces that it has delivered a large apeture space telescope structure to its customer, EOI Space (Louisville, Colo., U.S.) for its very low Earth orbit (LEO) constellation that is currently in development.

RWC provided engineering design, analysis and fabrication services for this stable structure within a compressed 6-month schedule while meeting tight requirements. Once integrated with its optics and detectors, the telescope will provide near-real-time ultrahigh-resolution earth imaging services to EOI Space’s wide customer base.

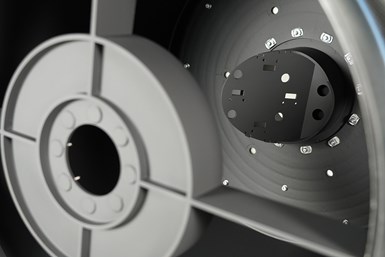

The telescope structure features mountings for three separate mirrors, as well as stress-free support of the imaging module and a decoupled mount to the spacecraft bus structure. Constructed of high modulus unidirectional carbon fiber-reinforced cyanate ester prepreg, aluminum honeycomb core and metallic inserts, the telescope was fabricated to meet the specific needs of EOI Space’s distinctive optical payload. While using the commonality of composite components to cut down on part count for the first deliverable, future iterations will be optimized for weight and producibility.

RWC provided clean sheet engineering and design for this telescope structure including static, quasi-static, modal, acoustic, thermal and deflection analysis to ensure all requirements were met for launch, orbital and operational conditions.

According to Geoff Pinto, program manager for the space telescope project at RWC, “We leveraged our deep background in stable space structure fabrication to achieve the demanding requirements of this program, and we were able to exceed those demands for our customer.”

For related content, read “Rock West Composites delivers composite assembly fixtures for NASA PASS program.”

Related Content

-

Bladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

-

MFFD longitudinal seams welded, world's largest CFRTP fuselage successfully completed

Fraunhofer IFAM and partners have completed left and right welds connecting the upper and lower fuselage halves and sent the 8×4-meter full-scale section to ZAL for integration with a cabin crown module and testing.

-

JEC World 2024 highlights: Thermoplastic composites, CMC and novel processes

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.