Qarbon Aerospace successfully completes icing tunnel test for Helios system

Patented Helios Ice Protection technology uses an embedded heated graphite layer to heat composite structures significantly faster than legacy systems.

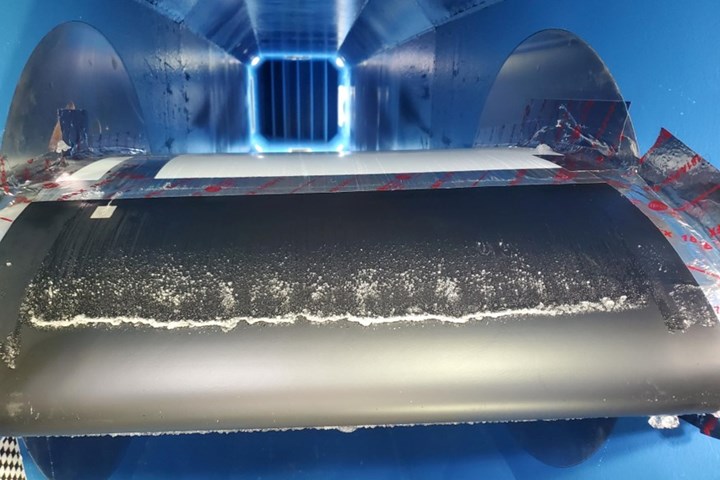

This image illustrates an ice shape at the maximum time between shed cycles at a relatively mild appendix C condition. The purpose is to determine a safe pulsing sequence to avoid large enough ice shape that could cause the aircraft to stall. Helios can pulse in such a way that has proven greater than 50% power efficiency since inception thanks to continuous development. Photo Credit, all images: Qarbon Aerospace.

Qarbon Aerospace Inc. (Red Oak, Texas, U.S.) has successfully completed another icing tunnel test of the company’s patented Helios Ice Protection system. The technology uses a heated graphite layer embedded in a thermoplastic composite leading edge. The graphite’s thermal conductivity is said to produce heat significantly faster than legacy ice protection systems, which is a crucial benefit in ice protection technologies.

The Helios test articles used for the icing tunnel test used Teijin (Tokyo, Japan) carbon fiber materials and Web Industries’ (Marlborough, Mass., U.S.) Precision BiasPly technology. The patented technology produces bias-ply composites that enable high-scale production in application-specific formats, increasing efficiency and reducing waste.

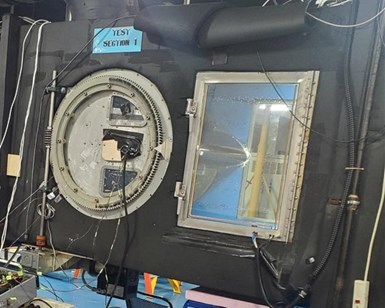

Illustrated here is Qarbon’s test article mounted to a closed-loop icing wind tunnel able to test various CFR part 25 appendix C and few appendix O conditions.

According to Qarbon Aerospace, the successful Helios icing tunnel test validated a manufacturing concept for advanced manufacturing processes and low electrical power requirements. The Helios Ice Protection electro-thermal system replaces bulky rubber pneumatic boots, gates, valves, tubing, controller, hardware and nacelle heating systems.

Qarbon Aerospace is a provider of large, complex composite and metallic structural components and assemblies such as fuselages, wings, flight control surfaces, and engine nacelles and components. Qarbon Aerospace operates nearly two million square feet of factory space across three facilities located in Red Oak, Texas; Milledgeville, Georgia; and Rayong, Thailand.

The company has vertically integrated manufacturing capabilities from component fabrication through large-scale assembly as well as proprietary thermoplastics technologies. Such technologies are being used to inform or develop advanced structures in civilian vertical life vehicles, the HEXA eVTOL aircraft and Virgin Galactic’s Delta-class spaceships.

Related Content

-

Materials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

-

One-piece, one-shot, 17-meter wing spar for high-rate aircraft manufacture

GKN Aerospace has spent the last five years developing materials strategies and resin transfer molding (RTM) for an aircraft trailing edge wing spar for the Airbus Wing of Tomorrow program.

-

Materials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.