People in Composites: April 2019

CW’s monthly roundup of people news in the composites industry.

AOC Aliancys

AOC Aliancys (Collierville, Tenn., U.S.) has promoted Fletcher Lindberg to vice president, Sales & Marketing for the Americas region. Lindberg has been with the company since 1996, most recently serving as vice president, Marketing for the Americas.

Lindberg graduated from Auburn University with a Bachelor of Science in Marketing and earned a Masters of Business Administration from the University of Memphis.

ASTM International

ASTM International’s (W. Conshohocken, Pa., U.S.) committee on composite materials (D30) in April presented its top annual award – the Award of Merit – to Adam J. Sawicki, technical fellow, structures technology, at Boeing (Ridley, Pa., U.S.). The prestigious award, which includes the accompanying title of fellow, is ASTM’s highest recognition for individual contributions to developing standards.

The committee honored Sawicki for exceptional leadership and dedication and with a commitment to excellence in the development, evolution and use of standards related to composite materials and their structures.

An ASTM International member since 2000, Sawicki has previously been awarded the Distinguished Service Award (2006), the Award of Appreciation (2007, 2009), the Service Award from the committee on standards (2008), and the Outgoing Chairman Award (2018). In addition to the committee on composite materials, Sawicki is a member of the committees on adhesives (D14) and additive manufacturing technologies (F42).

Sawicki has been with Boeing since 1990, serving in a variety of roles. He holds a bachelor’s degree and master’s degree in science of aeronautics and astronautics from the Massachusetts Institute of Technology and an MBA from Villanova University.

National Composites Centre

The University of Bristol (Bristol, U.K.) and the National Composites Centre (NCC, Bristol, U.K.) have announced Professor Ole Thybo Thomsen as NCC Chair in Composites Design and Manufacturing.

Thomsen will lead composites manufacturing and design research activities at Bristol Composites Institute (ACCIS), the collaboration between the University and the National Composites Centre and with the EPSRC Future Composites Manufacturing Research Hub (CIMCOMP).

Previously Thomsen was Professor of Structures and Materials at the University of Southampton (Southampton, U.K.) where he was also Head of the Infrastructure Research Group. His experience includes positions at Aalborg University, Denmark; the European Space Agency, European Space Research and Technology Centre, the Netherlands. In addition, he has held visiting professor positions with the Department of Mechanical Engineering and Center for Composite Materials, University of Delaware and Israel Institute of Technology.

Prof Thomsen has a distinguished record of research in composites design and methodologies that bridge design, manufacturing, modeling, validation and certification. He is Principal Investigator of the recently awarded £6.7M EPSRC Programme Grant ‘Certification for Design – Reshaping the Testing Pyramid’.

Scaled Composites

Scaled Composites (Mojave, Calif., U.S.) has announced Cory Bird as the company’s new president. Scaled Composites is an industry leader with broad experience in vehicle design, tooling, and manufacturing; specialty composite structure design, analysis and fabrication; and developmental flight test.

Bird has over 33 years of experience at Scaled Composites, holding multiple positions, including project engineer, program manager, Stratolaunch chief engineer, vice president/general manager and executive vice president/chief technical officer.

Over the course of his career, Bird has held increasing roles of responsibility directly supporting design, development and execution of over 45 prototype vehicles including milestone aircraft like SpaceShipOne, WhiteKnightOne and GlobalFlyer.

Shape

Shape Machining Ltd. (Witney, U.K.) has announced that Brian Campbell has joined the company as operations manager.

Campbell joins Shape from respected Formula One team Williams Grand Prix Engineering, where he spent 29 years, starting as a pattern maker and working his way up through the company to manufacturing manager.

Shape primarily machines complex patterns, molds, jigs & fixtures from epoxy tooling boards and intricate composite cores from Rohacell foam.

Tooling Tech Group

Tooling Tech Group (TTG, Macomb, Mich., U.S.) has announced that Lee Childers, former TTG COO, has been named company CEO. Childers will lead the Tooling Tech Group’s operations that provide a vast array of highly engineered design, tooling solutions and automation equipment to the company’s Tier 1 and OEM customers and will report directly to the board of directors.

Childers joined TTG as COO in early 2018, bringing 33 years’ experience in developing business plans, growth strategies and leading operations for Tier-1 suppliers including United Technologies, Lear Corporation, IAC Group and, most recently, as COO of Crowne Group.

Lee Childers is a graduate of Southern Illinois University, Carbondale with degrees in chemistry and business administration as well as being a current member of the Mechanical Engineering Advisory Board for Lawrence Technological University (Southfield, Mich.).

Anthony C. Seger, founder and former CEO of the Tooling Tech Group will be moving into a board role to continue advising and supporting the Tooling Tech management team. Seger has spent his entire career in the tooling field and is recognized as an industry leader in several areas, including thermoforming and foundry innovation, while also holding multiple United States patents.

Tooling Tech Group provides die cast and stamping dies; composite compression, rotational and blow molds; thermoform and waterjet tooling; trim dies and fixtures; and automation solutions.

Related Content

PRF Composite Materials introduces primer, adhesive films

Novel RFA570 eXpress cure adhesive film and RF Primer are compatible with PRF’s full range of epoxy prepregs formulations.

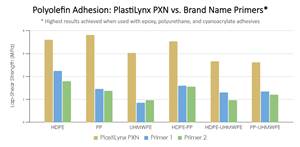

Read MoreXlynX’s PlastiLynx PXN crosslinking primer enhances polymer adhesion

PFAS-free diazirine primer makes surfaces receptive to all manner of adhesives, including epoxies and polyurethanes, outperforming alternative options by 150-350%.

Read MoreMaterials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

Read MoreMaterials & Processes: Tooling for composites

Composite parts are formed in molds, also known as tools. Tools can be made from virtually any material. The material type, shape and complexity depend upon the part and length of production run. Here's a short summary of the issues involved in electing and making tools.

Read MoreRead Next

Composites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read More

.png;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)