XlynX’s PlastiLynx PXN crosslinking primer enhances polymer adhesion

PFAS-free diazirine primer makes surfaces receptive to all manner of adhesives, including epoxies and polyurethanes, outperforming alternative options by 150-350%.

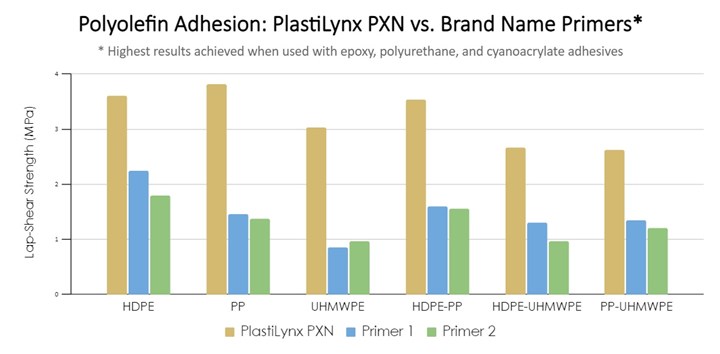

Head-to-head comparison of PlastiLynx PXN versus brand name polyolefin primers. Source | XlynX Materials

XlynX Materials (Victoria, Canada) announces the launch of PlastiLynx PXN, an advanced PFAS-free universal primer that modifies the surfaces of hard-to-bond polyolefins to enable strong adhesion with glues, coatings and dyes. This chemical crosslinking technology provides compatibility with low surface energy polymers like polypropylene (PP) and polyethylene (PE), aiming to surpass conventional primers and surface treatments.

PlastiLynx PXN is the latest and most advanced version of XlynX’s polymeric diazirine primer, providing improved adhesion while also eliminating fluorine from its chemical composition. Head to head against the established brand name polyolefin primers, PlastiLynx PXN reportedly provided between 150% to 350% stronger adhesion in PP/PE substrate tests. Moreover, it showed strong compatibility with every type of bulk adhesive tested.

XlynX says that the primer will work with composite materials provided the matrix is either an epoxy, polyurethane, amine reactive polymer or a polyolefin that can be crosslinked to. The fibers used also need to be compatible with diazirine insertion, such as UHMWPE fiber.

Unlike commercial polyolefin primers, which are designed to function primarily with cyanoacrylate-type adhesives, PlastiLynx PXN is a universal primer that makes surfaces receptive to all manner of adhesives, including epoxies and polyurethanes. XlynX Materials tested PlastiLynx PXN with more than 15 different leading adhesives — many specifically designed for polymers — and in every case, polymer adhesion was significantly improved. By being able to select the right adhesive for the job, manufacturers can choose from a variety of cost-effective adhesives that work with a much broader range of substrates and applications.

The product’s versatility is a result of the permanent covalent bonds it forms with the substrate surface, leaving a reactive amine layer that is receptive to adhesives, dyes and coatings. Compared to traditional surface modification techniques for polyolefins like plasma and corona, PlastiLynx PXN is a long-lasting treatment that remains active for months and does not damage the substrate surface.

Topically applied and cured rapidly with UV light or moderate heat, PlastiLynx PXN unlocks new design opportunities, manufacturing efficiencies and dissimilar bonding applications. With the release of PlastiLynx PXN, XlynX Materials is now able to offer a full suite of advanced PFAS-free diazirine adhesives and primers designed specifically for polyolefin applications.

Related Content

-

Epoxy-based structural film adhesive intended for aerospace, MRO

CAMX 2023: Park Aerospace is presenting its new aerospace-grade film adhesive material Aeroadhere FAE-350-1, in addition to other product offerings intended for aerospace, defense and spacecraft.

-

Pro-Set named official materials supplier for New York Yacht Club American Magic

Competitive sailing team prepares for the 37th America’s Cup beginning in August 2024 with adhesives, resins and laminate testing services for its AC75 monohull construction.

-

Scott Bader partners with Elixir for Crestabond distribution in India

Crestabond MMA structural adhesives range will continue to drive advanced composites growth in India, in addition to Scott Bader’s global expertise and local technical support.