NASA selects Rocket Lab to launch composite solar sail

NASA’s Advanced Composite Solar Sail System is expected to launch from Rocket Lab’s Electron carbon fiber composite launch vehicle in mid-2022.

Rocket Lab USA Inc. (Long Beach, Calif., U.S.), a leader in launch services and space systems, has been selected to launch NASA’s (Washington D.C., U.S.) Advanced Composite Solar Sail System (ACS3) on its Electron launch vehicle.

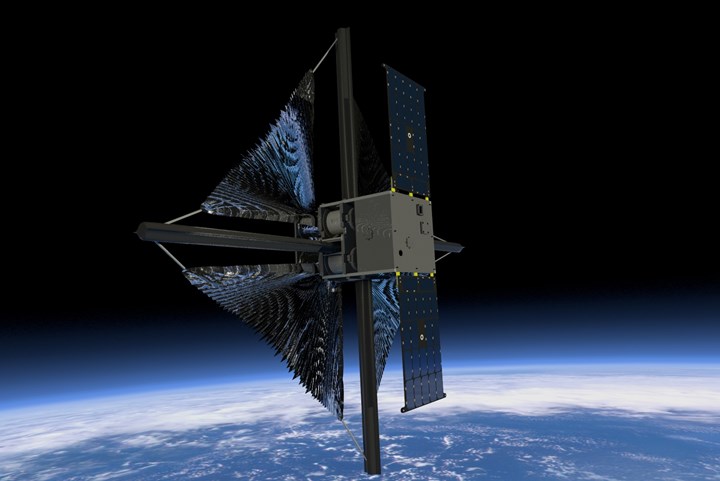

NASA’s ACS3 technology uses composite materials in its novel, lightweight booms that deploy from a CubeSat to support a solar sail. Solar sails are designed to employ the pressure of sunlight for propulsion, eliminating the need for a conventional rocket propellant.

ACS3 is scheduled for lift-off from Rocket Lab Launch Complex 1 in mid-2022. The Electron launch vehicle’s Kick Stage is capable of deploying individual satellites to unique orbits even when flying as part of a rideshare, which was a key factor in Rocket Lab being selected as the launch provider. ACS3 requires a higher altitude than the other rideshare payloads launching on the same mission, so after deploying the first payloads, the Kick Stage will perform another burn with its 3D-printed Curie engine to raise the orbit and deploy ACS3.

According to NASA, data obtained from the ACS3 demonstration will guide the design of future larger scale composite solar sail systems that could be used for space weather early warning satellites, near-Earth asteroid reconnaissance missions or communications relays for crewed exploration missions.

Peter Beck, Rocket Lab’s founder and chief executive, says, “It seems fitting to launch NASA’s Advanced Composite Solar Sail System on Electron, the world’s first full carbon [fiber] composite orbital launch vehicle. We’re excited to see composites used yet again to unlock new capabilities in space.”

Related Content

-

Otto Aviation launches Phantom 3500 business jet with all-composite airframe from Leonardo

Promising 60% less fuel burn and 90% less emissions using SAF, the super-laminar flow design with windowless fuselage will be built using RTM in Florida facility with certification slated for 2030.

-

Plant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

-

Prepreg compression molding supports higher-rate propeller manufacturing

To meet increasing UAV market demands, Mejzlik Propellers has added a higher-rate compression molding line to its custom CFRP propeller capabilities.