Mechnano trademarks CNT dispersion process for AM materials

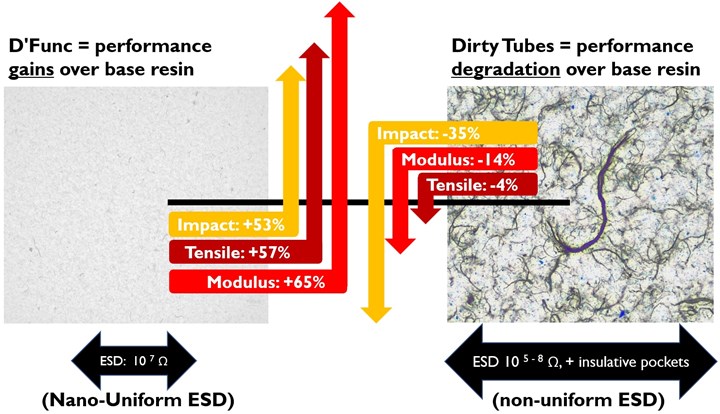

D’Func dispersions eliminate clumped and roped CNTs, leading to increased electrical and mechanical performance in 3D-printed parts.

3D printing startup Mechnano (Mesa, Ariz., U.S.) has trademarked its proprietary process that eliminates clumped and roped carbon nanotubes (CNTs) and makes CNT dispersions discrete, dispersed and functionalized, leading to increased electrical and mechanical performance in the company’s additive manufacturing (AM) masterbatches and materials.

The process, called D’Func, is represented by more than 130 issued patents, reportedly solving the problems caused by dispersions of “dirty tubes” (clumped CNTs) into materials. Dirty tube dispersions are mechanically inferior to their base formulas — resulting in broken parts or processes that need to be shut down as replacements are put in place. In contrast, D’Func dispersions improve mechanical properties of AM materials.

In electrostatic discharge (ESD) applications, dirty tubes leave insulative pockets that reject charges trying to dissipate to the ground, clump into ropes that create lightning rod effects that destroy electronics and leave residual metals from the CNT creation process that cause additional electrical and mechanical part failures.

“Mechnano’s D’Func dispersions are by nature clean and are the answer for today’s increasingly stringent requirements for true static dissipation by AM fabricated parts from resins, powders, pellets and beyond,” Mechnano President Bryce Keeler says. “D’Func provides nano-uniform ESD protection throughout the part, regardless of the process, which is why it is becoming the industry standard for AM providers who want consistent, reliable, nano-uniform ESD properties.”

The term “D’Func” stems from the firm’s research and development (R&D) lab, playfully named “Funkytown” for the work performed there to functionalize and disperse Mechnano’s discrete CNTs. While its scientists have fun with their naming conventions, Keeler says they’re serious about developing new solutions that leverage Mechnano’s D’Func technology.

Trademarking D’Func helps clearly differentiate Mechnano’s intellectual property and R&D advances.

Related Content

-

Price, performance, protection: EV battery enclosures, Part 1

Composite technologies are growing in use as suppliers continue efforts to meet more demanding requirements for EV battery enclosures.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

Thermoplastic composites welding advances for more sustainable airframes

Multiple demonstrators help various welding technologies approach TRL 6 in the quest for lighter weight, lower cost.