MAXBlade project to advance tidal energy generation with 13-meter composite blades

Recently launched 66-month MAXBlade project aims to harness tidal energy in the U.K. through a 70% increase in rotor swept area.

Her Royal Highness, The Princess Royal, addresses guests during her visit to FastBlade on Jan. 17. Photo Credit: Neil Hanna

MAXBlade, a €10 million project, funded by the European Union (EU) and UK Research and Innovation, has been launched to deliver a range of innovations to improve the performance of tidal turbines and reduce costs. The project was inaugurated in the presence of Her Royal Highness, The Princess Royal, at the University of Edinburgh’s (U.K.) FastBlade facility, reported to be the world’s first rapid testing facility for tidal turbine blades.

MAXBlade will investigate the full lifecycle of tidal turbine blades, from materials, manufacture and operation, to decommissioning and recyclability. The project’s long-term aim is to ensure the European composite sector becomes the international leader in tidal blade manufacture.

The project plans to increase the area harnessed by Scottish tidal technology company Orbital Marine Power (Edinburgh) to generate power — known as the rotor swept area — by 70%, to more than 1,000 square meters. To achieve this, MAXBlade will increase the length of tidal turbine blades from 10 to 13 meters — making them the longest of their kind. The team says that boosting blade length will have the single greatest impact on reducing the cost of tidal energy.

“This [the MAXBlade project] will help the tidal energy industry to de-risk their ongoing turbine developments and provide low-cost, reliable renewable energy to the grid.”

Modeling by the University of Edinburgh’s Institute of Energy Systems estimates £40 billion could be generated for the U.K. economy by harnessing wave and tidal energy.

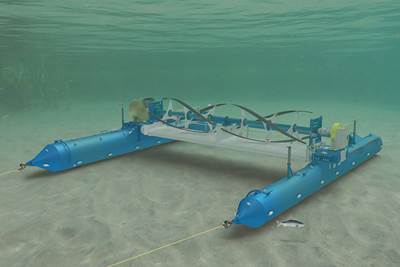

MAXBlade will involve a two-year design and development phase, followed by an 18-month build, during which blades will undergo advanced structural testing at FastBlade. The technology will then undergo two years of real-world testing at the European Marine Energy Centre (EMEC) in Orkney. Two of Orbital Marine Power’s O2 floating tidal turbine platforms will each be fitted with four of the newly developed blades. In total, the project is expected to run from 66 months (January 2023 to June 2028).

The team aims to generate 120,000 hours of performance data that will be assessed by EMEC and project partner Tecnalia (Derio, Biscay, Spain), a research and technological development center.

Innovations from MAXBlade will be integrated with findings from its sister project, FORWARD2030, to enable large-scale production of Orbital’s O2 turbine technology. This will pave the way to the tidal energy sector making significant contributions towards Europe’s energy systems, energy security and industrial development by 2030 and beyond to 2050, the team says.

“The University of Edinburgh is delighted to be a partner in the MAXBlade project, where we will demonstrate the unique rapid testing capability of the FastBlade facility,” Professor Conchúr Ó Brádaigh, head of school and chair of materials engineering at Edinburgh University, says. “This will help the tidal energy industry to de-risk their ongoing turbine developments and provide low-cost, reliable renewable energy to the grid. We will also lead the development of thermoplastic resins in MAXBlade and the circular economy roadmap needed for future tidal blade manufacturing and recycling.”

MAXBlade is led by TechnipFMC and includes Orbital Marine Power, Marasoft, Tecnalia, University of Edinburgh, EMEC, Laborelec and the European Composites Industry Association. It is supported by Edinburgh Innovations, the University of Edinburgh’s commercialization service.

Related Content

Carbon fiber composite hydrofoils to enable “world’s fastest” electric ferry

The Candela P-12 Shuttle, set to launch in Stockholm, Sweden, in 2023, will incorporate lightweight composites and automated manufacturing to combine speed, passenger comfort and energy efficiency.

Read MorePlant tour: Avel Robotics, Lorient, France

From AFP hydrofoils to more efficient aircraft parts, Avel uses digital design, multiprocess production and a rule-breaking approach for complex 4D composites.

Read MoreMaterials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

Read MoreJEC World 2022, Part 1: Highlights in sustainable, digital, industrialized composites

JEC World 2022 offered numerous new developments in composites materials, processes and applications, according to CW senior editor, Ginger Gardiner, most targeting improved sustainability for wider applications.

Read MoreRead Next

Éirecomposites and ORPC to use recycled carbon fiber in tidal turbine foils

Development part of €3M CRIMSON project to advance tidal energy for clean electricity.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read More