GWEC 2024 report highlights positive momentum in wind installation

Global Wind Report describes a record year for wind energy in 2023, but highlights the need for policy-driven action to meet COP28 and 1.5°C pathway targets.

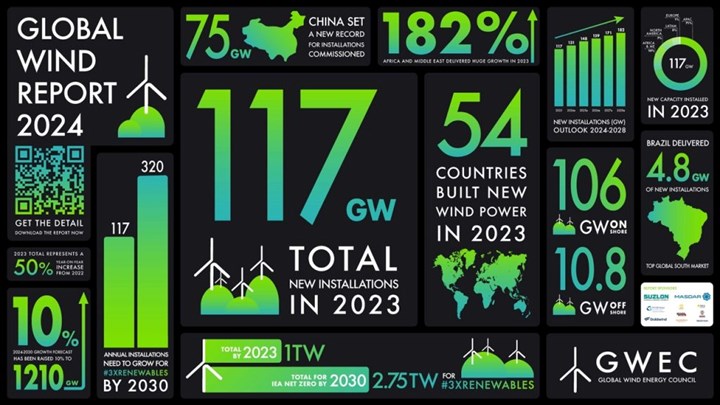

The Global Wind Energy Council (GWEC, Brussel, Belgium) has announced the release of the “Global Wind Report 2024,” which cites the installation of 117 gigawatts (GW) of new capacity in 2023, making it the best year for new wind energy. Despite a turbulent political and macroeconomic environment, GWEC says that the wind industry is entering a new era of accelerated growth driven by increased political ambition, manifested in the historic COP28 adoption of a target to triple renewable energy by 2030.

The report highlights increasing momentum on the growth of wind energy worldwide:

- Total installations of 117 GW in 2023 represents a 50% year-on-year increase from 2022;

- 2023 was a year of continued global growth — 54 countries representing all continents built new wind power, with 10.8 GW total installed for offshore wind;

- Top five markets for new wind installations are China, the U.S., Brazil, Germany and India;

- China’s growth underpinned a record year for the Asia-Pacific region with year-on-year growth of 106%;

- Latin America also experienced record growth in 2023, with year-on-year growth of 21%, led by Brazil’s new installations of 4.8 GW, which registered as third globally;

- Wind installations in Africa and the Middle East increased by 182% compared with 2022;

- GWEC has revised its 2024-2030 growth forecast (1,210 GW) upwards by 10%, in response to the establishment of national industrial policies in major economies, gathering momentum in offshore wind and promising growth among emerging markets and developing economies.

Still, the wind industry must roughly triple its annual growth from a level of 117 GW in 2023 to at least 320 GW by 2030 to meet the COP28 and 1.5°C pathway targets.

The Global Wind Report provides a roadmap for how this can be done. GWEC calls on policymakers, investors and communities to work together across the key areas of investment, supply chains, system infrastructure and public consensus, to set the conditions for wind energy growth to take off through to 2030 and beyond.

“It’s great to see wind industry growth picking up, and we are proud of reaching a new annual record. However much more needs to be done to unlock growth by policymakers, industry and other stakeholders to get on to the three-times pathway needed to reach net zero,” Ben Backwell, GWEC CEO, says. “Growth is highly concentrated in a few big countries like China, the U.S., Brazil and Germany, and we need many more countries to remove barriers and improve market frameworks to scale up wind installations.”

Geopolitical instability may continue for some time, Backwell notes, but as a key energy transition technology, the wind industry needs policymakers to be laser-focused on addressing growth challenges such as planning bottlenecks, grid queues and poorly designed auctions. “These are the measures that will significantly ramp up project pipelines and delivery, rather than reverting to restrictive trade measures and hostile forms of competition,” he says.

Visit this link for access to the full report.

Related Content

-

Drag-based wind turbine design for higher energy capture

Claiming significantly higher power generation capacity than traditional blades, Xenecore aims to scale up its current monocoque, fan-shaped wind blades, made via compression molded carbon fiber/epoxy with I-beam ribs and microsphere structural foam.

-

Materials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

-

Materials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.