Graphene used to extend rechargeable battery life

Researchers from Western University finds that adding a carbon-based graphene layer extends lithium-ion rechargeable battery life up to 50%.

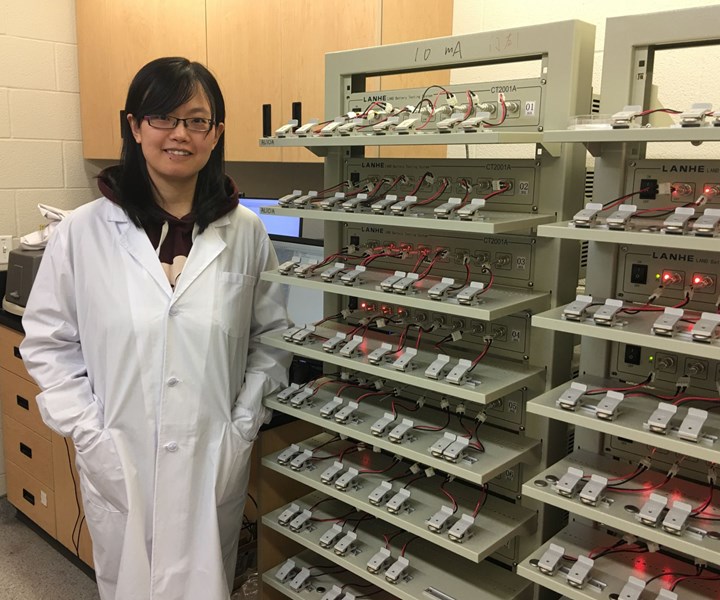

Xia Li, Mitacs Postdoc Fellow in Western’s Faculty of Engineering Source | Western Universityh

Researchers from Western University (London, Ontario, Canada), using the Canadian Light Source (CLS) — a synchotron powered light source — at the University of Saskatchewan (Saskatoon, Saskatchewan, Canada), has found that adding a carbon-based layer to lithium-ion rechargeable batteries extends their life up to 50%.

Aluminum foil is commonly used on the cathode as current collector where electricity leaves the battery of rechargeable lithium-ion batteries. This foil has high electronic conductivity and is lightweight and low cost, but the new generation of batteries brings new challenges to the current collectors, which will need even more chemical stability to protect against the corrosion of electrolyte in the cathode. Rather than find an entirely new material for cathodes, the Western team tested a super-thin carbon coating, also known as graphene, produced by 3M Canada (London, Ontario, Canada).

“We added a thin layer of carbon coating to the aluminum foil that conducts electric current in rechargeable batteries,” says Xia Li, a Mitacs postdoc fellow in Western’s Faculty of Engineering and lead researcher of the study. “It was a small change, but we found the carbon coating protected the aluminum foil from corrosion of electrolyte in both high voltage and high energy environments — boosting the battery capacities up to 50% more than batteries without the carbon coating.”

In addition to the graphene coating, 3M Canada supplied the CLS, which uses extremely bright X-rays to identify the chemical changes occuring on delicate battery surfaces as they are operating. Analysis showed that the carbon-based coating is effective in both high-voltage and high-energy environments, which would be important for applications like electric vehicles.

Related Content

-

Low-cost, efficient CFRP anisogrid lattice structures

CIRA uses patented parallel winding, dry fiber, silicone tooling and resin infusion to cut labor for lightweight, heavily loaded space applications.

-

Bladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

-

Plant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.