Element Materials Technology invests in hydrogen capabilities

Backed by recently acquired Filton Systems’ digital engineering and aerospace capabilities and composite tanks testing, and NTS Laboratories’ H2 facility, Element adds new equipment, expands team for H2 advancement.

Element Materials Technology (London, U.K.), a testing, inspection and certification (TIC) services provider, has completed the first part of its $10 million investment into new hydrogen state-of-the-art testing equipment and expanding its dedicated global hydrogen team, in an effort to meet increasing demand from its customers who are transitioning to cleaner energy solutions and using hydrogen throughout various product lifecycles and systems.

These efforts complement Element’s existing services, encompassing areas such as digital modeling and simulation, support for carbon capture usage and storage (CCUS) projects, the development of aerospace and transportation fuel tanks and systems, and the establishment of pipeline and storage facilities for the energy sector.

To bolster its capabilities, Element has developed specialized static and dynamic fracture mechanics equipment for its laboratories in the U.K. and Europe. This equipment enables hydrogen testing at pressures of up to 100 barg, frequencies below 1 hertz and at cryogenic temperatures of up to -269ºC, in a variety of test frame configurations. The equipment will be used to assess hydrogen infrastructure and storage systems under different in-situ temperatures and pressures.

At Element’s Malvern, U.K. facility, 11 chambers conduct electromagnetic compatibility (EMC) testing to ensure the seamless operation of complex electronic components in modern vehicles. Recently, Element has upgraded its large equipment chamber with safety systems to test hydrogen-fueled vehicles and other equipment using hydrogen as fuel, catering to customers entering this emerging market.

Element’s recent acquisition of Filton Systems Engineering (FSE, Bristol, U.K.), an aerospace engineering and testing services business, further enhances and complements these hydrogen-related offerings. Filton, with its team of 50 experts, brings extensive expertise in gaseous and liquid hydrogen, supported by a dedicated facility in Kemble, U.K., featuring an in-house-designed liquefaction plant. FSE also has experience developing and testing Type III and IV tanks. This complements the acquisition of NTS Laboratories in the U.S. last year, which has a dedicated hydrogen facility in San Bernardino, Calif., U.S. that was previously used to support the space market with fluid flows and liquid hydrogen.

A dedicated hydrogen team has been established at Element, comprising experts in fuel cells, infrastructure, electrolyzers, cryogenics, process and functional safety. Working across a variety of market sectors for hydrogen, they are situated to coordinate services across Element’s laboratories worldwide. This team, in conjunction with the skills and capabilities of FSE, forms a wealth of knowledge and experience that can be applied to customer projects related to hydrogen, carbon capture and infrastructure transition — across the full value chain and product life cycles.

“As hydrogen takes center stage in the global clean energy market, the materials and infrastructure involved present new challenges and contexts for use,” Mark Eldridge, director of hydrogen at Element, says. “With our deep expertise in materials science, corrosion, coatings and electrochemistry, we offer state-of-the-art testing, certification and consulting services for various aspects of hydrogen-related technologies. Coupled with our digital engineering expertise, these services expedite time-to-market, crucial in achieving stringent net-zero targets.”

Safety remains a paramount concern at Element, with a focus on advancing safe, hydrogen-related technologies within this team. This commitment is also evident across the wider Element service offering in physical testing, including engineering critical assessments covering welds, corrosion, coatings, electrochemistry, fracture mechanics, fatigue testing, permeation analysis and materials validation. Hydrogen digital engineering, including modeling, simulation and computational fluid dynamics, supports these testing efforts.

Related Content

JEC World 2022, Part 1: Highlights in sustainable, digital, industrialized composites

JEC World 2022 offered numerous new developments in composites materials, processes and applications, according to CW senior editor, Ginger Gardiner, most targeting improved sustainability for wider applications.

Read MoreCummins debuts 15-liter hydrogen engine and partners with Daimler for fuel cell trucks

Full-scale production of H2 ICE expected in 2027 while Daimler Truck will have initial fuel cell trucks available to select North American customers in 2024.

Read MoreNCC reaches milestone in composite cryogenic hydrogen program

The National Composites Centre is testing composite cryogenic storage tank demonstrators with increasing complexity, to support U.K. transition to the hydrogen economy.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreRead Next

Report addresses advancements, challenges in hydrogen value chain

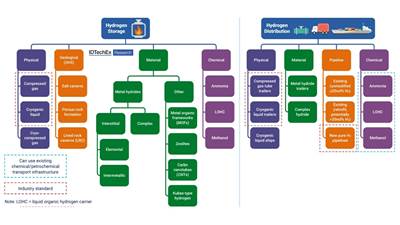

IDTechEx gives an overview of the solutions that currently exist for hydrogen storage and distribution, and how these two components are vital to ensuring the full potential of this rapidly growing sector.

Read MoreForvia begins Type IV hydrogen tank rollout from mass production plant

From tank manufacturing to complete storage systems, the automotive technology company cites a mid-term capacity of 100,000 tanks per year.

Read MoreNCC composite cryogenic tanks successfully tested with LH2

Thirty-liter single-piece and split-piece tank constructions underwent various pressures and test cycles while maintaining full integrity. End boss design testing is underway.

Read More