Avient launches reclaimed nylon-based long fiber composites

The post-consumer recycled nylon 6 material is reclaimed from end-of-life fishing nets, reducing ocean-bound plastic waste while fostering material deployment for demanding environments.

Photo Credit: Avient Corp.

Avient Corp. (Avon Lake, Ohio, U.S.) announces the commercial availability of Complēt R long fiber-reinforced composites, which incorporate post-consumer recycled nylon 6 material reclaimed from end-of-life (EOL) fishing nets.

“We’re delighted to be introducing our first recycled content long fiber composite material in a planned larger portfolio based on recycled resin,” says Eric Wollan, general manager for long fiber technologies at Avient. “Historically, it has been a challenge to source streams of recycled resins that are compatible with the pultrusion process used to manufacture long fiber composites. But we’re committed to leading the industry by offering sustainable options even in our performance-critical materials like long fiber composites.”

Aiming to create a positive environmental impact by reducing ocean-bound plastic waste, Complēt R nylon 6 long fiber composites can help OEMs to meet their goals for using materials containing recycled content, Avient says. Potential markets contain those whose products involve structural applications often deployed in demanding environments. Examples include lighter weight adventure gear for outdoor recreation, next-generation vehicles that go further using fewer energy resources and recycled content office furnishings that contribute towards LEED certification for buildings.

Complēt™ R nylon 6 long fiber composites provide stiffness, strength and toughness performance on par with standard nylon 6 long fiber formulations using virgin resin. Using these composites as a metal replacement also reportedly fosters significant weight reductions along with the time and cost saving benefits of single-step injection molding.

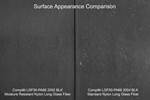

Formulations are available globally in a standard black color at typical weight percentages of long glass fiber, long carbon fiber or hybrid combinations. Levels of post-consumer resin content vary within the offerings, which allows end products to meet different performance and sustainability requirements.

Related Content

-

Thermoplastic composites welding advances for more sustainable airframes

Multiple demonstrators help various welding technologies approach TRL 6 in the quest for lighter weight, lower cost.

-

The state of recycled carbon fiber

As the need for carbon fiber rises, can recycling fill the gap?

-

Plant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.